Staged vacuum drying treatment process and treatment device for oilfield drilling cuttings

A processing device and oilfield drilling technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problems of insufficient dryness of discharged cuttings, harsh operating conditions, high cost, etc., and achieve cuttings treatment High efficiency, compact device structure, and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

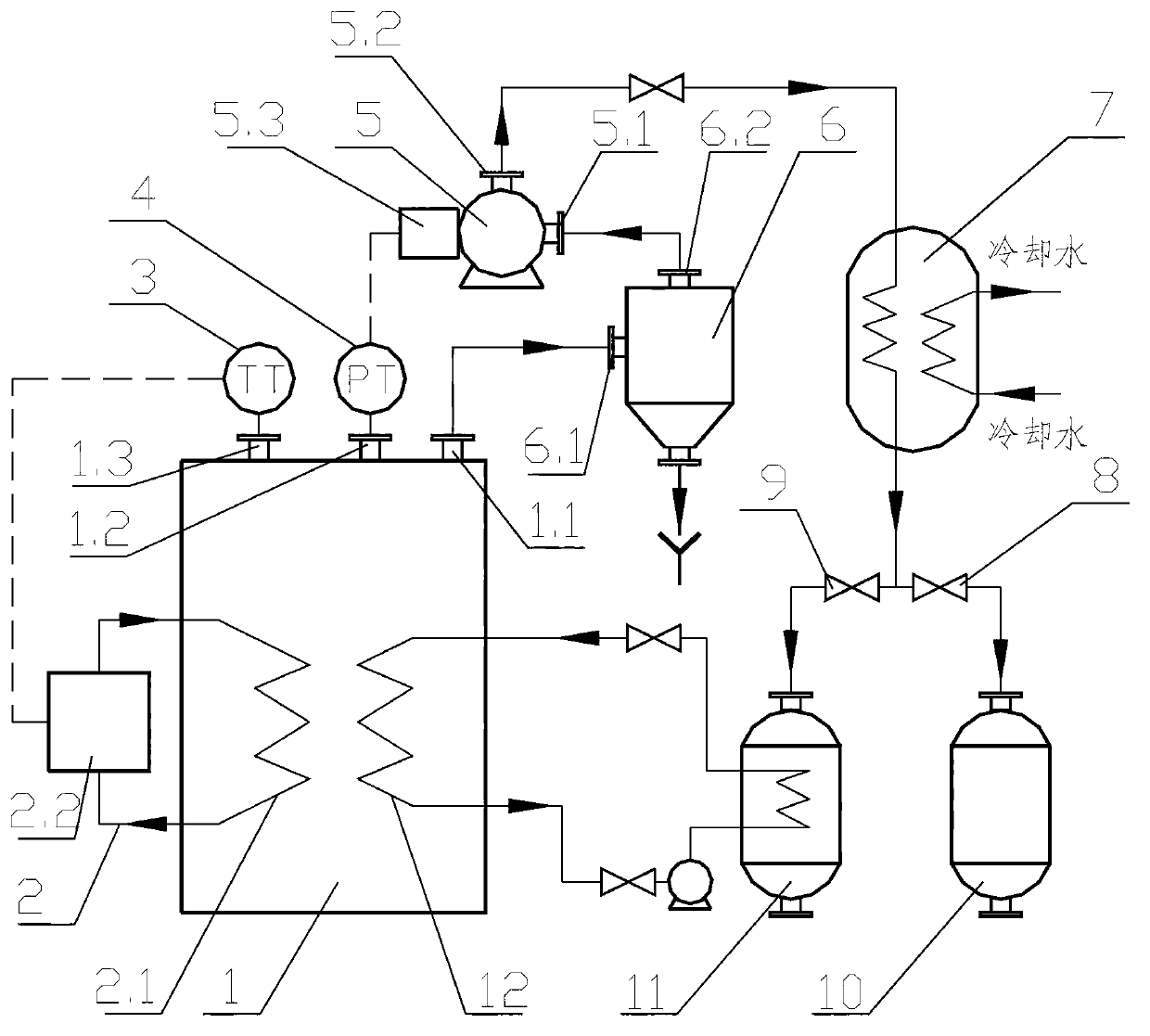

[0019] refer to figure 1 , the temperature measuring port 1.3 of the vacuum dryer 1 is installed with a temperature sensor 3, the temperature sensor 3 is connected to the heating controller 2.2, and the signal of the temperature sensor 3 is fed back to the heating system 2; the pressure measuring port 1.2 of the vacuum dryer 1 is installed with a pressure sensor 4, a pressure sensor 4 Connect with the vacuum unit controller 5.3, and the pressure sensor 4 signals back to the vacuum unit 5; the heater 2.1 of the heating system 2 is installed in the vacuum dryer 1, and the steam extraction port 1.1 of the vacuum dryer is connected to the dust collector material inlet 6.1 of the dust collector 6 Connection, the dust collector gas outlet 6.2 is connected to the vacuum unit inlet 5.1, the vacuum unit outlet 5.2 is connected to the condenser 7, and the condenser 7 is connected to the oil storage tank 10 and the storage tank through the oil storage tank inlet valve 8 and the water stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com