Single-waterproof temperature-sensitive label-use paper

A heat-sensitive and labeling technology, which is applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of insufficient waterproof effect, long curing time, and low production efficiency, and achieve low cost, short curing time and fast production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings.

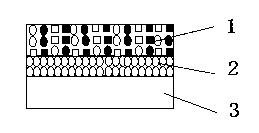

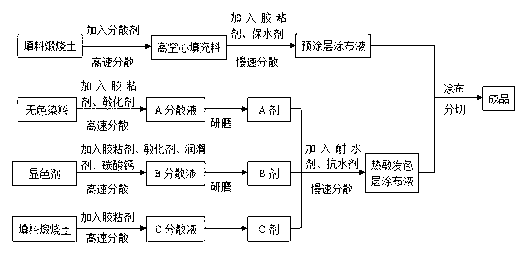

[0034] As shown in the accompanying drawings, the single waterproof thermal label paper of the present invention is composed of a thermal chromophoric layer 1, a precoat layer 2 and a high-quality base paper layer 3 in order from top to bottom. The thermal chromophoric layer 1 It is coated with a coating solution for a heat-sensitive chromophoric layer, and the coating solution for the heat-sensitive chromophore adopts a polycarbon-grade phenolic substance or a diphenyl sulfone substance as a color developer, and the single-waterproof heat-sensitive label paper is The production process is as follows:

[0035] (1) Preparation of pre-coating coating liquid:

[0036] Add a certain amount of water to the pre-coating batching tank, open the batching tank and stir, add calcined kaolin with a particle size of about 2um, the oil absorption value is 40~55, add a pigment dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com