Copper oxidation discoloration resistant agent and preparation method thereof

A discoloration agent and copper oxidation technology, applied in the field of metal corrosion protection, can solve the problems of chromate mutagenic cytogenetics, toxicity, carcinogenicity, etc., and achieve the effects of good anti-oxidative discoloration, simple process and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

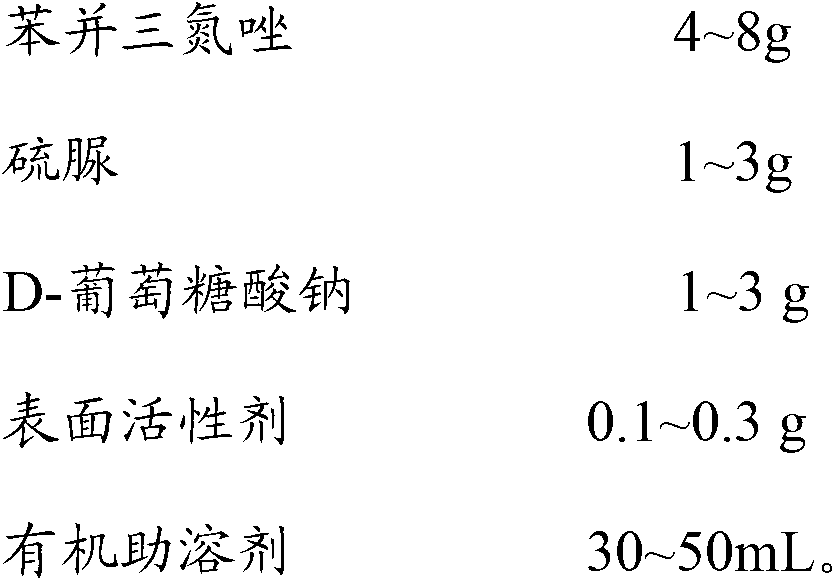

[0030] (1) Use deionized water as the solvent, and weigh each component according to the following ratio:

[0031] Benzotriazole 4g;

[0032] Thiourea 1g;

[0033] Sodium D-gluconate 1g;

[0034] Sodium lauryl sulfate 0.2g;

[0035] Ethanol 30mL;

[0036] (2) Dissolve 4g of benzotriazole in 30mL of ethanol to obtain solution 1;

[0037] (3) Dissolve 1g of thiourea in 200mL of deionized water to obtain solution 2;

[0038] (4) Dissolve 1g of sodium D-gluconate in 200mL of deionized water to obtain solution 3;

[0039] (5) After uniformly mixing the above solution 1, solution 2 and solution 3, add 0.2g of sodium lauryl sulfate, and use deionization to make the volume to 1L, keep stirring for 15 minutes, then let stand for 30 minutes and filter to obtain the obtained The anti-copper oxidation discoloration agent.

[0040] Heat the above-mentioned anti-copper oxidation and discoloration agent to 60°C, put the copper-plated parts into it and soak for 2 minutes, then take it ...

Embodiment 2

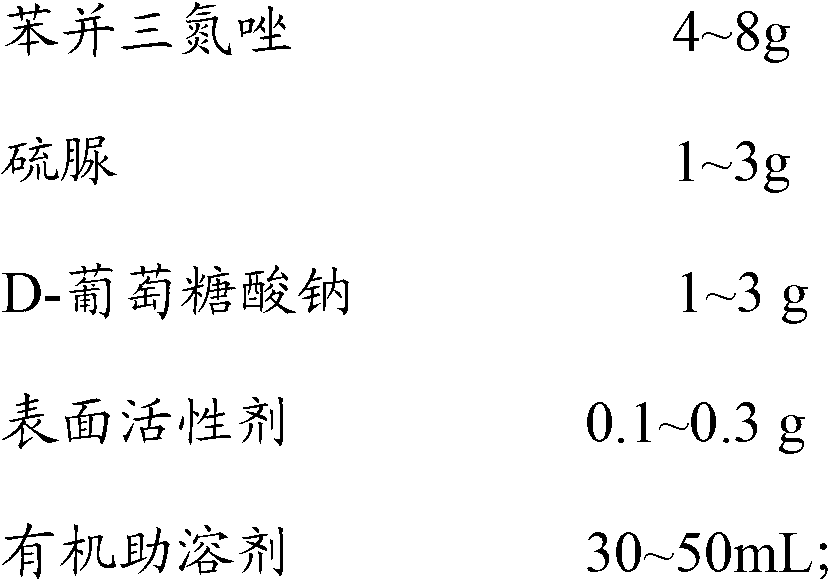

[0042] (1) Use deionized water as the solvent, and weigh each component according to the following ratio:

[0043] Benzotriazole 6g;

[0044] Thiourea 2g;

[0045] Sodium D-gluconate 2g;

[0046] Sodium lauryl sulfate 0.1g;

[0047] Ethanol 40mL;

[0048] (2) Dissolve 6g of benzotriazole in 40mL of ethanol to obtain solution 1;

[0049] (3) Dissolve 2g of thiourea in 200mL of deionized water to obtain solution 2;

[0050] (4) Dissolve 2g sodium D-gluconate in 100mL deionized water to obtain solution 3;

[0051] (5) After uniformly mixing the above solution 1, solution 2 and solution 3, add 0.1g of sodium lauryl sulfate, and use deionization to make the volume to 1L, keep stirring for 15 minutes, then let stand for 30 minutes and filter to obtain the obtained The anti-copper oxidation discoloration agent.

[0052] Heat the above-mentioned anti-copper oxidation and discoloration agent to 60°C, put the copper-plated parts into it and soak for 2 minutes, then take it out, w...

Embodiment 3

[0054] Dissolve 8 g of benzotriazole in 50 ml of ethanol to obtain solution 1, dissolve 3 g of thiourea in 200 ml of deionized water to obtain solution 2, dissolve 3 g of sodium D-gluconate in 100 ml of deionized water to obtain solution 3, and dissolve solution 1 , Solution 2 and Solution 3 were mixed evenly, and 0.3 g of sodium lauryl sulfate was added, and deionized water was added to make the volume to 1 L, and the final solution was stirred for 15 minutes and then allowed to stand for 30 minutes to obtain the required anti-copper discoloration agent product .

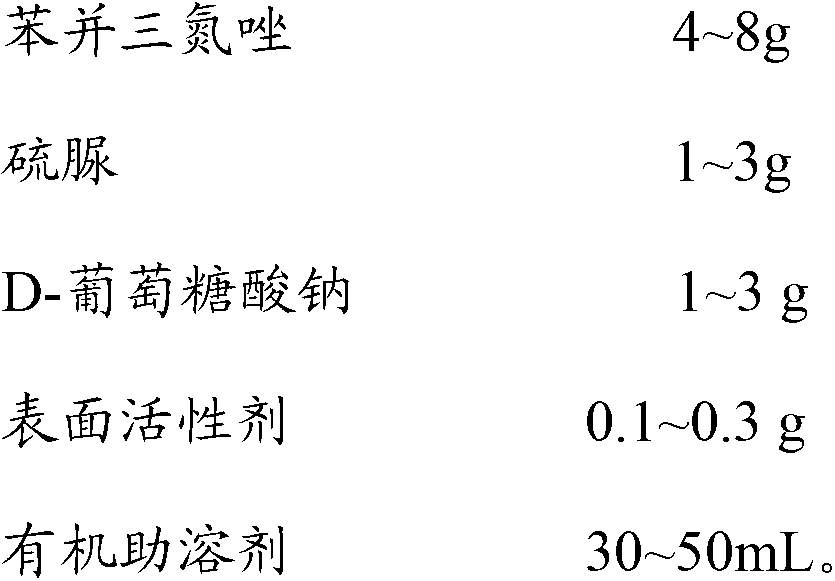

[0055] (1) Use deionized water as the solvent, and weigh each component according to the following ratio:

[0056] Benzotriazole 8g;

[0057] Thiourea 3g;

[0058] Sodium D-gluconate 3g;

[0059] Sodium lauryl sulfate 0.3g;

[0060] Ethanol 50mL;

[0061] (2) Dissolve 8g of benzotriazole in 50mL of ethanol to obtain solution 1;

[0062] (3) Dissolve 3g of thiourea in 200mL of deionized water to obtain solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com