Material for fiber manufacturing and fiber

A technology of fiber and liquid crystal polyester, which is applied in the field of fiber manufacturing materials and fibers, can solve problems such as viscosity increase, achieve high fiber strength, and improve fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

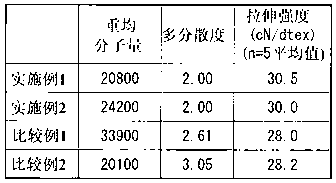

[0147] The present invention is illustrated by examples below, but the present invention is not limited to these examples.

[0148] [Melt Viscosity]

[0149] Melt viscosity is measured by using a flow characteristic tester (Capirograph) 1B manufactured by Toyo Machinery Seisakusho Co., Ltd., using a nozzle with a hole diameter of 0.5 mm and a shear rate of 1000 s for each measurement temperature. -1 conditions are measured.

[0150] [Flow start temperature]

[0151] The flow initiation temperature of the liquid crystal polyester, which is a raw material for fiber production, was measured using a flow characteristic evaluation device "Flow Tester CFT-500" manufactured by Shimadzu Corporation. Fill about 2 g of the sample into a capillary rheometer equipped with a die with an inner diameter of 1 mm and a length of 10 mm. 2 ) under a load of 4°C / min to extrude the liquid crystal polyester from the nozzle, the temperature at which the melt viscosity was 4800 Pa·s (48000 poise) ...

Embodiment 2

[0198] The liquid crystal polyester (A)-2-1 was pelletized in the same manner as in Example 1.

[0199] The obtained pellets had a melt viscosity of 35 Pa·s at 350° C. when measured under the above conditions. Generally, as the temperature increases, the melt viscosity of liquid crystal polyester decreases. Therefore, when the melt viscosity of liquid crystal polyester (A)-2-1 is measured at 360°C, a value lower than 35 Pa·s obtained as the above measurement result can be obtained. Value of melt viscosity. That is, it can be seen that the melt viscosity measured at 360° C. of the liquid crystal polyester (A)-2-1 is 70 Pa·s or less.

[0200] Using the obtained pellets, spinning was carried out in the same manner as in Example 1, and the tensile strength of the heat-treated yarn was measured.

[0201]

[0202] The liquid crystal polyester (A)-3-1 was pelletized in the same manner as in Example 1.

[0203] The obtained pellets had a melt viscosity of 35 Pa·s at 350° C. when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com