Small size environmental protection paper box folding machine

A folding machine, an environmentally friendly technology, applied in the direction of carton/carton manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of cumbersome manual folding carton steps, irregular and regular carton shapes, and long-term hands-on ability. Large market promotion space and application prospects, easy installation and layout, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

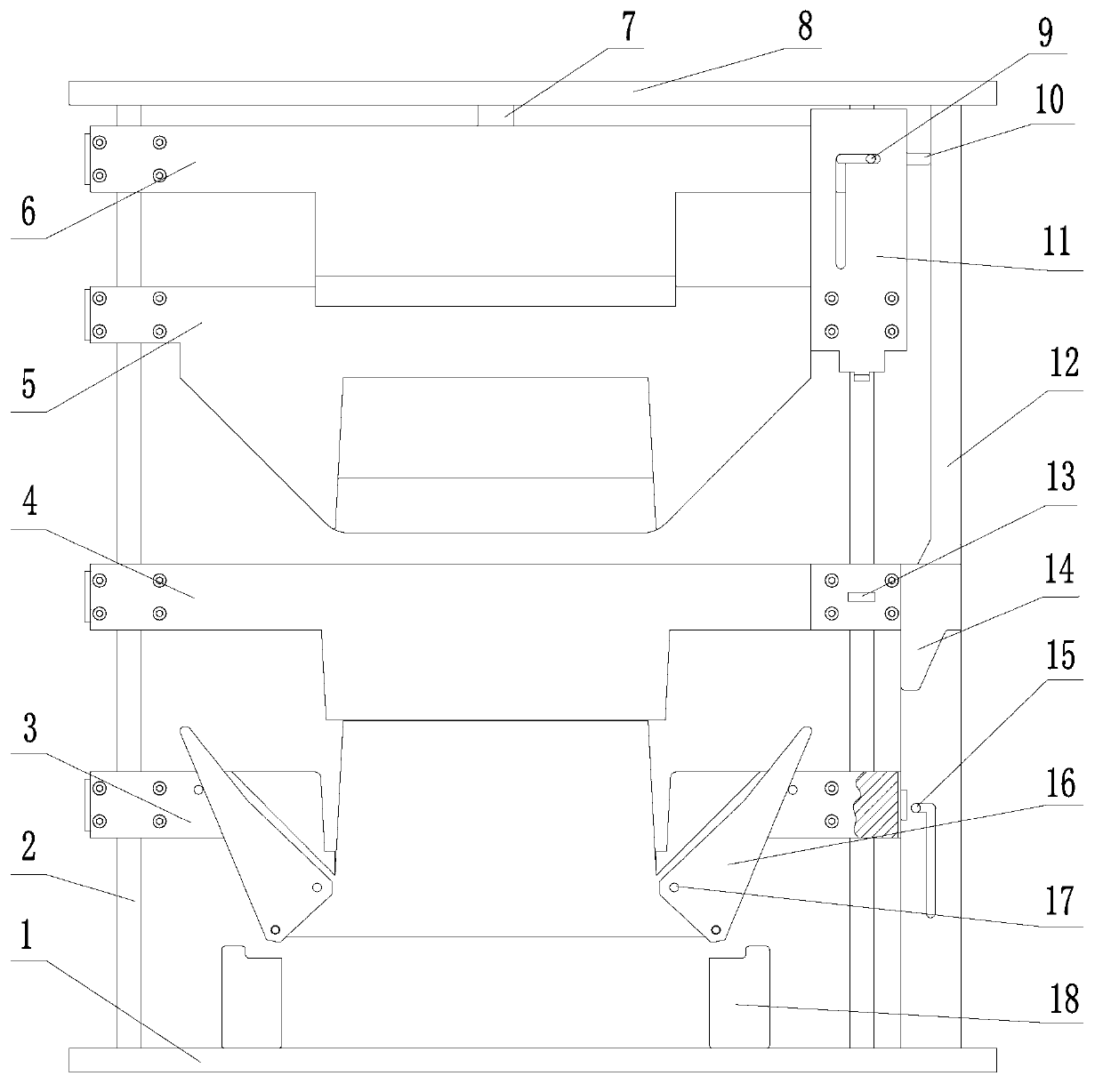

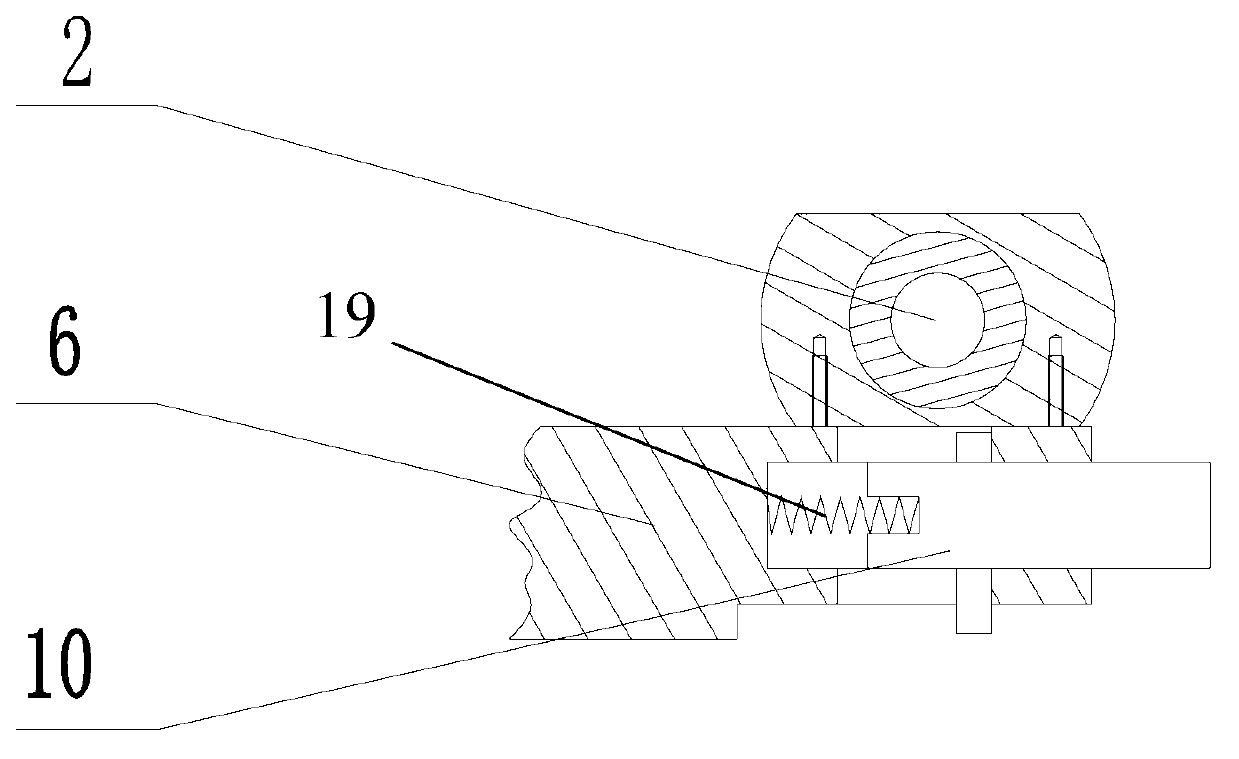

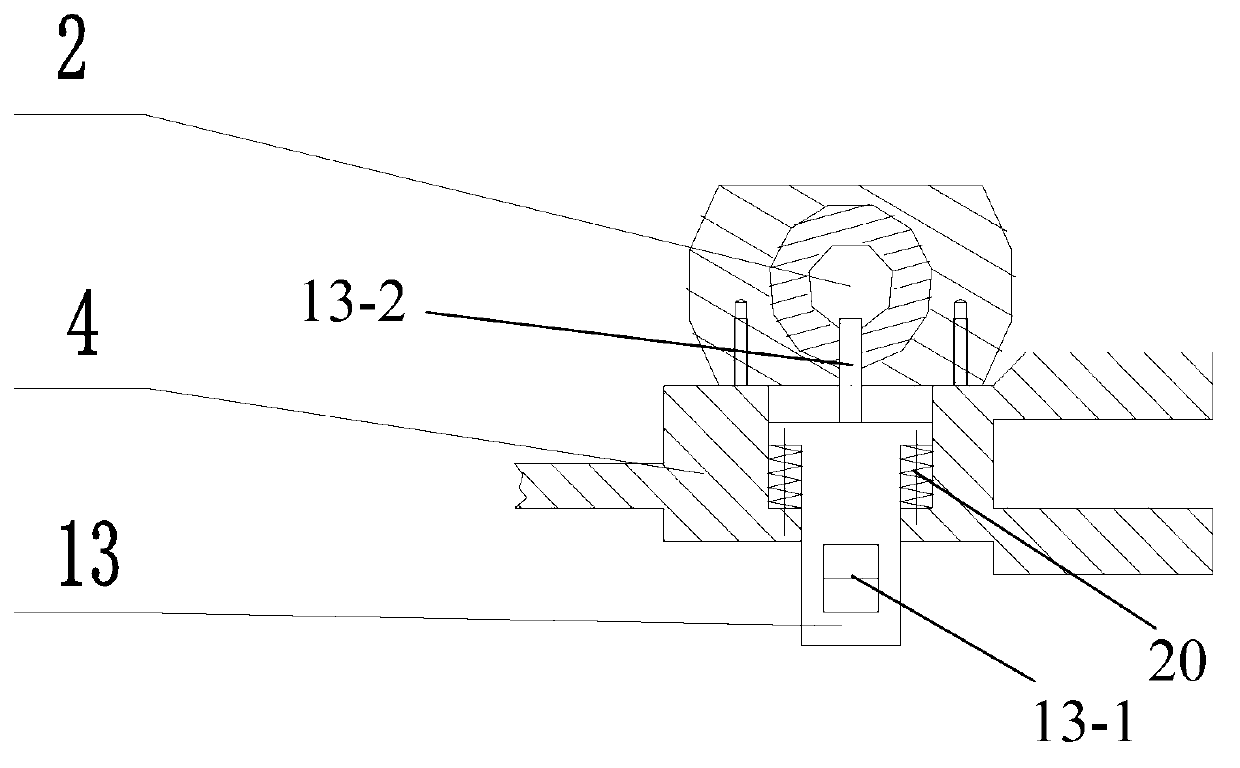

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] see Figure 1-3 , The small environmental protection carton folding machine in this embodiment includes a forming mold mechanism, a timing action mechanism, and a frame. The forming mold mechanism is arranged on the frame, and the action timing mechanism is installed on each sub-part of the forming mold mechanism. With the assistance of the sequential action mechanism, the forming die mechanism turns over the paper in a certain order, so as to fold the flat paper into an environmentally friendly open carton.

[0023] The frame includes a lower base plate 1, guide rails 2 on both sides, and an upper cover plate 8. The lower base plate 1 and the upper cover plate 8 are arranged in parallel, and two ends of the two are respectively fixed and vertically connected to a guide rail 2. A magnet 7 is fixedly installed downwards in the middle of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com