Automatic feeding device for grinding both sides of slip sheets

A technology of automatic feeding and double-sided grinding, which is applied to machine tools, grinding/polishing equipment, and grinding machines suitable for grinding workpiece planes. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

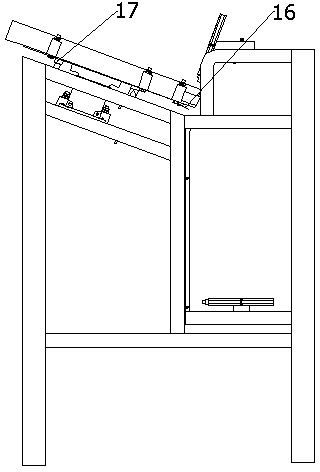

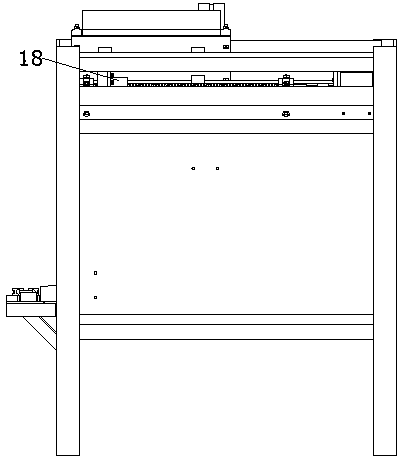

[0020] combine Figure 1~Figure 6 , the present embodiment is: the magazine box 9 that is filled with slide sheet to be processed is placed on the magazine box support 8 that is installed obliquely, takes off inserting piece 19 and magazine box lid 20. Take a hopper in the magazine 9 as a feeding cycle. Under the action of gravity, the sliding piece slides along the trough of the material box 9 to the lowest end of the material box 9, and the PLC controls the ejection cylinder 11 to push the sliding piece to push the spring piece 16 on the material box bracket 8 to the lowest end of the material box 9. The opening at the bottom of the end enters the slide track 15, and the slide automatically slides down to the lowest end of the slide track 15 due to gravity in the slide track 15, and enters the working area of the feeding cylinder 14, and the PLC controls the action of the feeding cylinder 14 Pushing slide sheet enters in the machine tool slide sheet support 13 of lathe 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com