Multi-station automatic scale division combination numerical control machine tool

An automatic indexing and CNC machine tool technology, applied in the field of CNC machine tools, can solve the problems of reducing product accuracy, workpiece shape and position tolerance, and low processing efficiency, and achieve the effect of improving processing efficiency and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

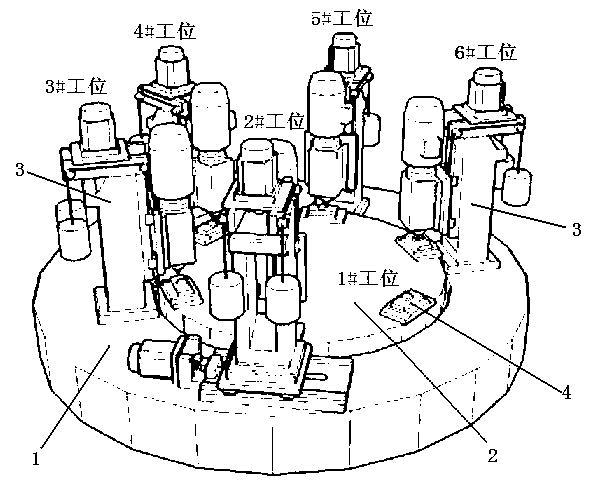

[0011] Such as figure 1 As shown, 1. Body, 2. Workbench, 3. Processing head, 4. Fixture.

[0012] Multi-station automatic indexing combined CNC machine tools, such as figure 1 As shown, it belongs to a kind of mechanical equipment that can carry out drilling, milling, reaming, tapping and other cycle processing of the workpiece in sequence. Machine head 3 and fixture 4 etc. constitute.

[0013] The fuselage 1 is a fixed circular platform structure, which is mainly used as the installation basis for other parts of the machine tool; the workbench 2 is installed in the installation groove provided on the fuselage 1, and the workbench 2 is a circular workbench , can also be designed as a rectangular or triangular workbench according to actual needs, and the top surface of the workbench is higher than the top surface of the fuselage. At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com