Numerically-controlled multi-station composite processing special machine tool for valve body of butterfly valve

A technology of composite processing and special machine tools, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of unsuitable for mass product processing, high price, low processing efficiency, etc., to achieve high practicability and promotion Value, simple and convenient operation, the effect of improving product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

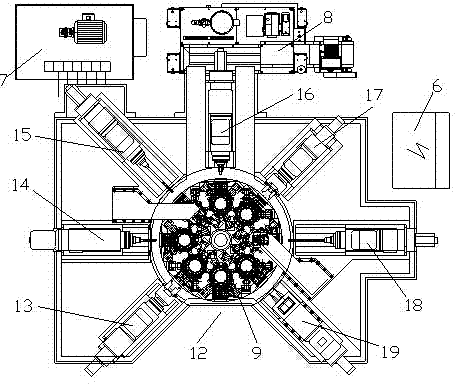

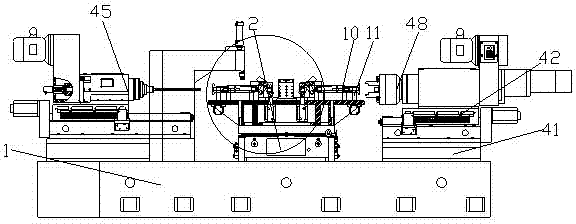

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

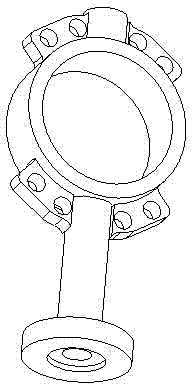

[0027] as attached Figure 2-9The shown special machine tool for multi-station composite processing of butterfly valve body according to the present invention includes a base 1, a workbench 2, a pressing fixture and a plurality of processing devices; the base 1 is provided with a workbench 2; The workbench 2 is a multi-station indexing and rotating workbench; the workbench 2 is provided with a compression fixture; The pressing device of the station and the rotary oil separator 4 located at the center of the clamp body 3; the processing devices are arranged around the workbench 2 according to the order of the processing procedures, and each processing device is arranged correspondingly to a station; The workbench 2 is an eight-station indexing hydraulic rotary workbench; the pressing device includes a pressing mechanism, a positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com