Tower crane standard section rotating tool

A tower crane and standard section technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to achieve tailor-welded integration, affecting product quality, and low positioning accuracy, improving processing accuracy and reducing labor. Effects of strength, guaranteed accuracy and verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

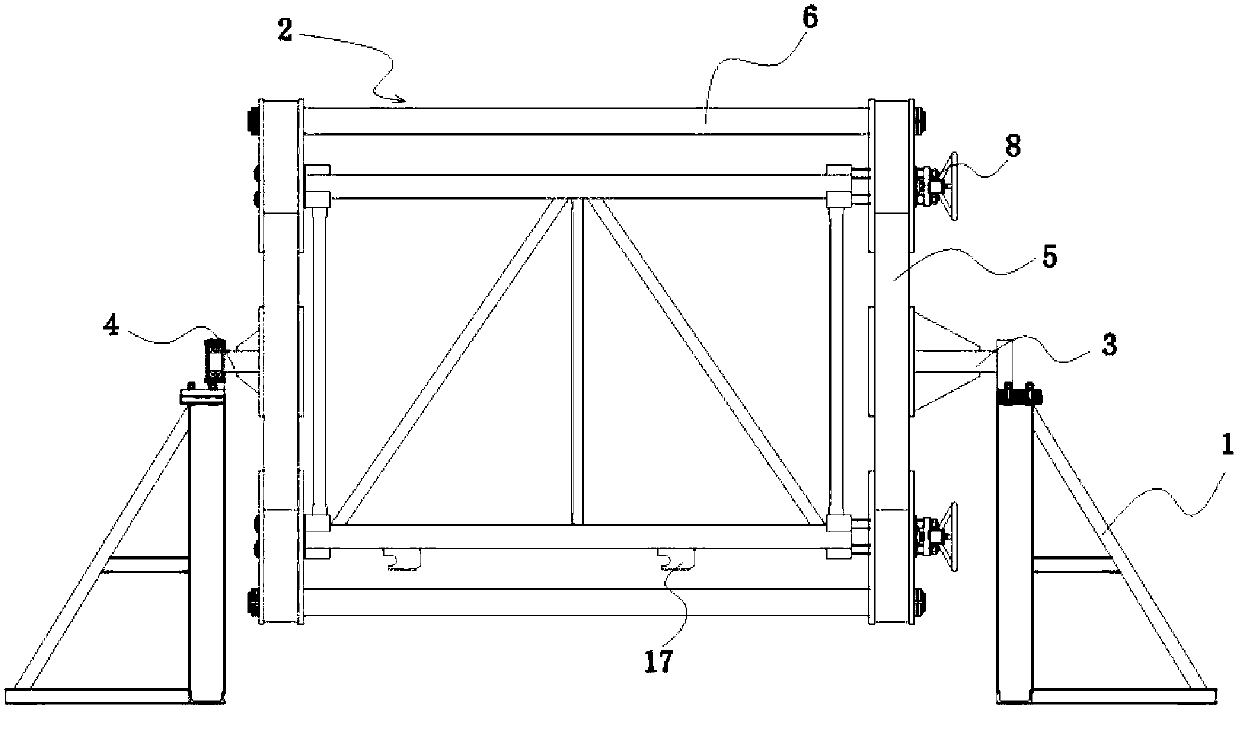

[0024] Such as Figure 1-3 As shown, the rotating tooling of the standard section of the tower crane includes an underframe 1 and a rotating mechanism 2. The rotating mechanism is rotatably connected to the underframe 1 through the long axis 3 and the short axis 4 at both ends of the rotating mechanism. It is composed of connecting columns 6 connected to the four corners of the wall panels at both ends. One end wall panel is provided with a fixed main rotary rod positioning shaft 7, and the other end wall panel is correspondingly provided with a main rotary rod jacking mechanism 8 for telescopic positioning.

[0025] Such as Figure 4 As shown, the jacking mechanism includes a hand wheel 9, a linkage plate 10, a screw mandrel 11, a positioning shaft 12, a positioning bushing 13, a screw mandrel overcoat 14 and a top tightening sleeve 15, and the positioning bushing 13 and the screw mandrel overcoat 14 are fixed on In the reserved hole of the wallboard, the positioning shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com