Device and method of main shaft flange end connecting hole machining in water pump

The technology of a processing device and processing method, which is applied in the field of processing devices for connecting holes at the flange end of the pump main shaft, can solve problems such as inability to guarantee product consistency and inconsistent equipment, and achieve reduced processing time and processing costs, low cost, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

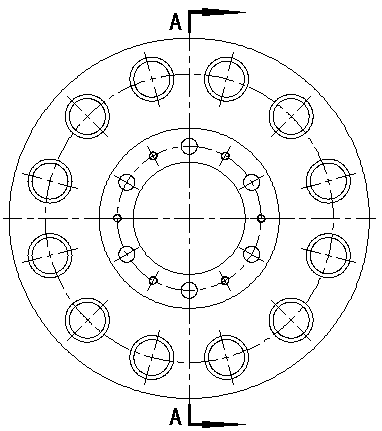

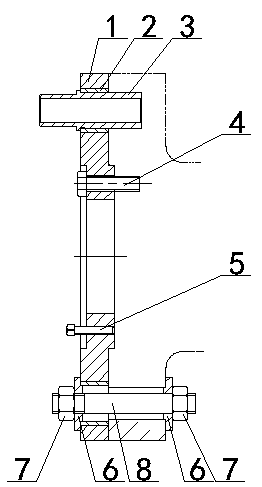

[0017] Embodiment 1: as figure 1 , 2 As shown, a connection hole processing device for the flange end of the water pump main shaft, the device includes a template 1, a plurality of positioning holes are uniformly distributed on the upper edge of the template 1, and a boring sleeve 2 is arranged in the positioning hole, In the positioning hole, a bolt 3 or / and a screw 8 with nuts 7 and washers 6 at both ends are arranged; on the template 1, a plurality of screw holes are evenly distributed inside the positioning hole, and in the screw holes A connecting screw 4 is arranged inside.

[0018] In order to facilitate disassembly, installation holes are provided between the adjacent screw holes, and jacking screws 5 are provided in the installation holes.

[0019] A method for processing a connection hole at the flange end of a water pump main shaft, the method steps are as follows: 1) Fasten the water pump main shaft and the motor main shaft with the connecting screw 4 after posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com