Method and inflatable rag for cleaning washing gap of roller washing machine

A technology for drum washing machines and washing tanks, which is applied to cleaning methods and utensils, chemical instruments and methods, and cleaning hollow objects. Tackling difficult-to-clean effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

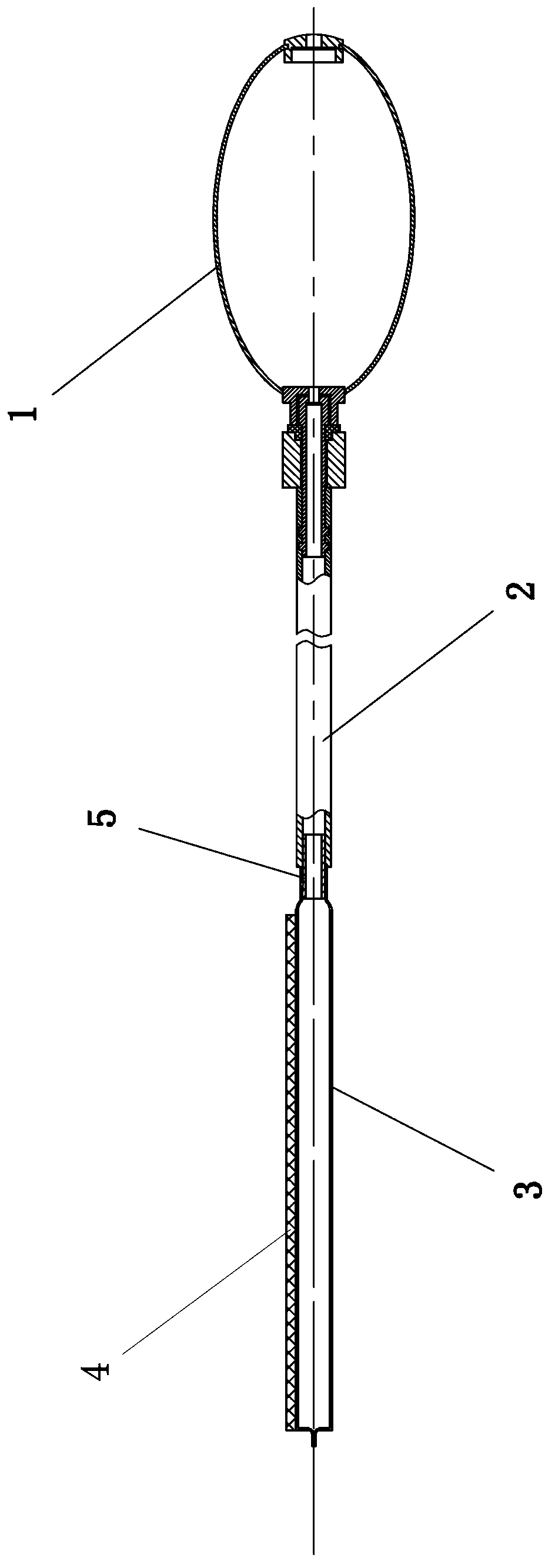

[0020] See figure 1 , the inflatable rag includes an inflation and deflation device 1 , a rubber hose 2 , an inflatable air bag 3 , a rag 4 and a connecting pipe 5 .

[0021] One end of the rubber hose 2 is fixedly connected to the inflation and deflation device 1 , and the other end is connected to the inflation air bag 3 through a connecting pipe 5 .

[0022] The materials of the inflation and deflation device 1 , the rubber hose 2 and the inflation air bag 3 are all rubber, and the material of the connecting pipe 5 is PMMA (polymethyl methacrylate). The inflation and deflation device 1 is provided with a valve.

[0023] Rag 4 is block, and its material is corduroy, and this rag 4 sews (also can adopt other ways to be fixedly connected) on inflatable air bag 3 side, and rag 4 is provided with dirt collection groove (not drawn among the figure).

[0024] The drum washing machine cleaned in this embodiment does not have the drum self-cleaning function, and the cleaning metho...

Embodiment 2)

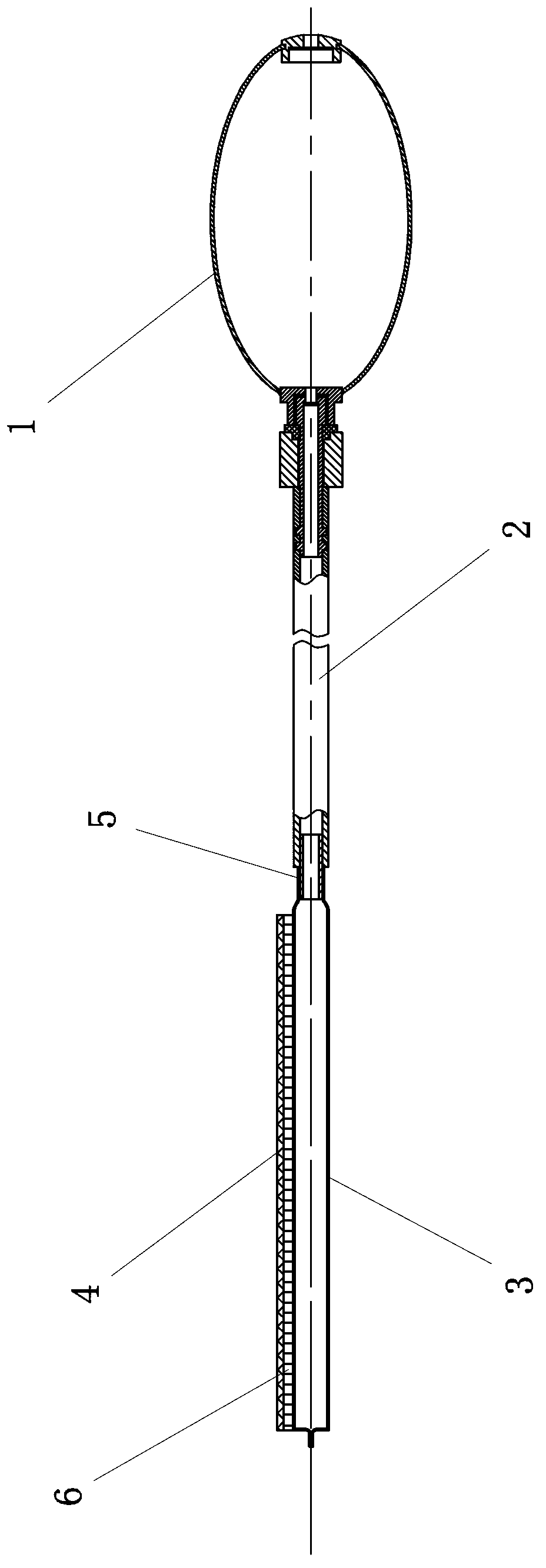

[0030] The inflatable rag of the present embodiment is basically the same as that of Embodiment 1, the difference is that (see figure 2 ): the rag 4 is bonded to one side of the inflatable airbag 3 through magic stickers 6 (commonly known as burrs), which facilitates the disassembly and cleaning of the rag 4 . The magic sticker 6 is made of nylon.

[0031] The cleaning method of this embodiment is the same as that of Embodiment 1.

Embodiment 3)

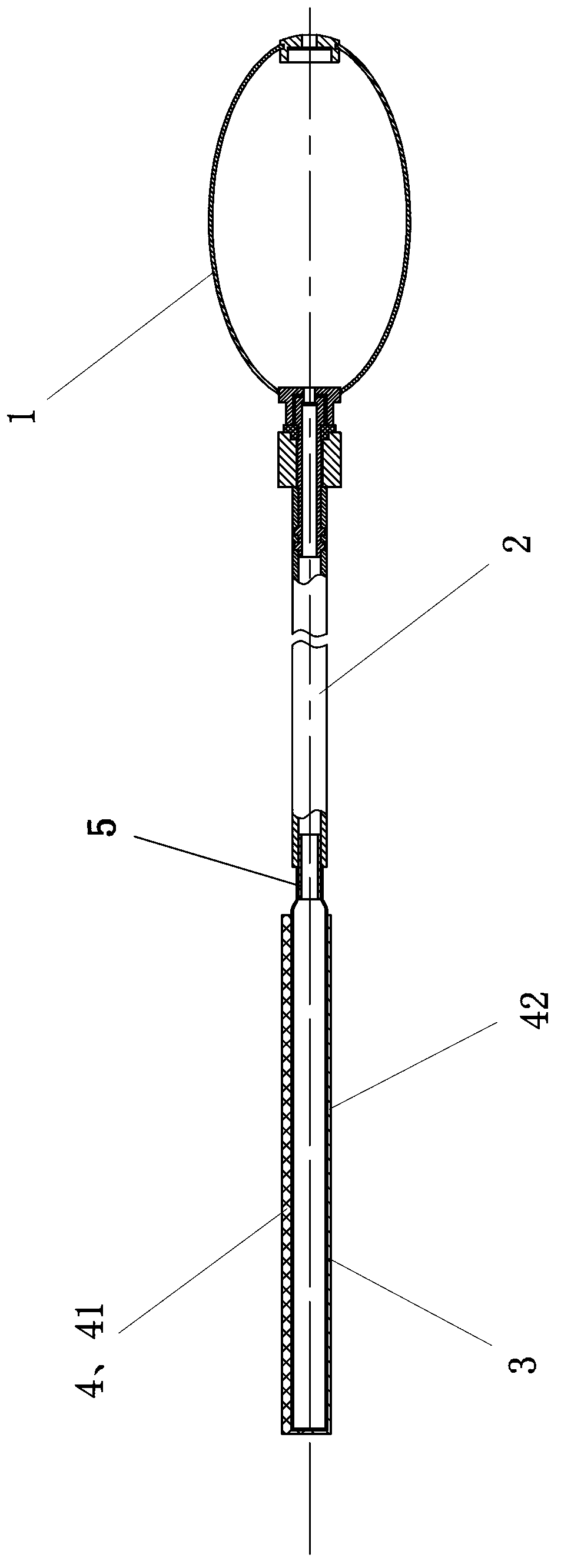

[0033] The inflatable rag of the present embodiment is basically the same as that of Embodiment 1, the difference is that (see image 3 ): the rag 4 is in the shape of a bag, so that it can be placed on the inflatable air bag 3, which is also convenient for disassembly and cleaning. The bag-shaped rag 4 is formed by pasting and sewing a rag piece 41 and a rubber sheet 42 , that is, one side is a rag piece 41 and the other side is a rubber sheet 42 .

[0034] The cleaning method of the present embodiment is basically the same as that of embodiment 1, the difference is:

[0035] The drum washing machine cleaned in this embodiment has a drum self-cleaning function.

[0036] The chemical cleaning process of step ② is as follows: pour 300g of sodium carbonate particles with a particle size of 3mm to 5mm into the washing tank of the drum washing machine, select the drum self-cleaning working state, and operate according to the drum self-cleaning program to complete a drum self-cleani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com