A kind of wood fiber reinforced gypsum board

A gypsum board and wood fiber technology, applied in the field of wood fiber reinforced gypsum board, can solve the problems of not being able to meet market demand, insufficient expansion rate compressive strength, unsatisfactory compressive strength, thermal conductivity, and unsatisfactory screw-holding force, and achieve the The effect of good thermal waterproof effect, large screw holding force and flexural modulus of elasticity, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A wood fiber reinforced gypsum board, which is prepared from the following raw materials in parts by weight:

[0018] Wood fiber 20, gypsum powder 100, humic acid 8, silicon carbide powder 10, corundum 10, calcium chloride 8, polyvinyl alcohol 6, starch ether 3, borax 2, ethanol 1 and 0.05% (according to 0.05g citric acid: 100ml Proportioning mode of water) citric acid aqueous solution 50.

[0019] The preparation method of the above-mentioned wood fiber reinforced gypsum board is carried out according to the following steps:

[0020] Weigh the raw materials according to the above order, put them into the mortar mixer one by one, add the raw materials while stirring evenly to obtain the mixed slurry, and let it stand for 30 minutes; then pour the mixed slurry into the mold and cast it into a plate, and demould after the plate is solidified, and finally The board is placed in a hot and humid environment with a temperature of 60°C and a humidity of 80% for 10 hours.

[...

Embodiment 2

[0023] A wood fiber reinforced gypsum board, which is prepared from the following raw materials in parts by weight:

[0024] Wood fiber 30, gypsum powder 120, humic acid 10, silicon carbide powder 15, corundum 15, calcium chloride 10, polyvinyl alcohol 8, starch ether 5, borax 4, ethanol 2 and 0.05% (according to 0.05g citric acid: 100ml Proportioning mode of water) citric acid aqueous solution 60.

[0025] The preparation method of the above-mentioned wood fiber reinforced gypsum board is carried out according to the following steps:

[0026] Weigh the raw materials according to the above order, put them into the mortar mixer one by one, add the raw materials while stirring evenly to obtain the mixed slurry, and let it stand for 30 minutes; then pour the mixed slurry into the mold and cast it into a plate, and demould after the plate is solidified, and finally The board is placed in a hot and humid environment with a temperature of 60°C and a humidity of 80% for 10 hours.

...

Embodiment 3

[0029] Test and detection of technical parameters of wood fiber reinforced gypsum board:

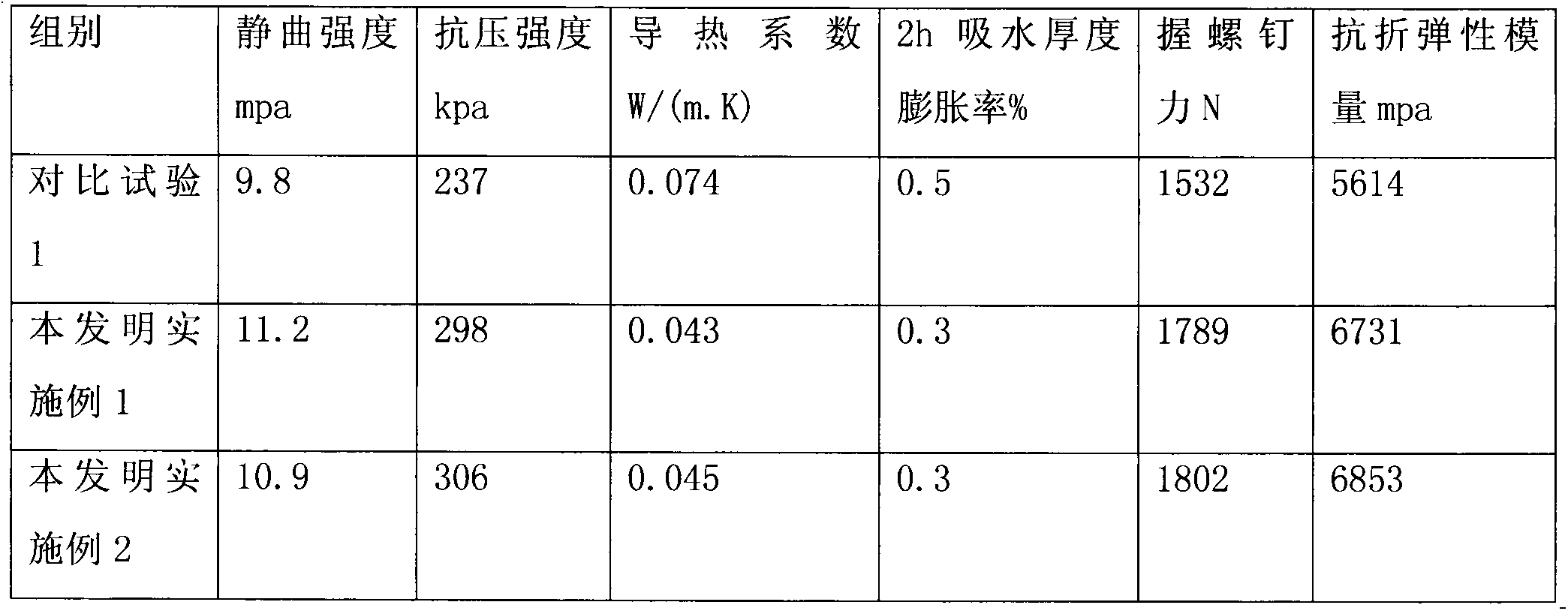

[0030] Comparative test 1: the wood fiber reinforced gypsum board prepared by the applicant earlier (see CN2007100974028); the gypsum board prepared in Example 1; the gypsum board prepared in Example 2.

[0031]

[0032] Through comparison, it is found that the wood fiber reinforced gypsum board prepared by the present invention is greatly improved in performance parameters such as static bending strength, compressive strength, thermal conductivity, 2h water absorption thickness expansion rate and flexural elastic modulus, and is completely superior to similar products in the market. It will have a better market prospect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com