Laser photovoltaic cell and production method thereof

A technology of laser photovoltaic cells and photovoltaic cells, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of PN junction leakage, conversion efficiency reduction, photovoltaic cell fill factor reduction, etc., to solve substrate leakage and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Taking into account the many shortcomings in the prior art, how to increase the parallel resistance, reduce the series resistance, increase the conversion efficiency of the laser battery, and solve the corresponding production technology is of great significance.

[0039] In order to solve the above problems, we propose to use a three-layer structure of polyimide layer, dielectric film SiN layer and metal light-shielding layer Au for isolation to reduce the parallel conductance of the battery PN junction, thereby improving the conversion efficiency of photovoltaic cells.

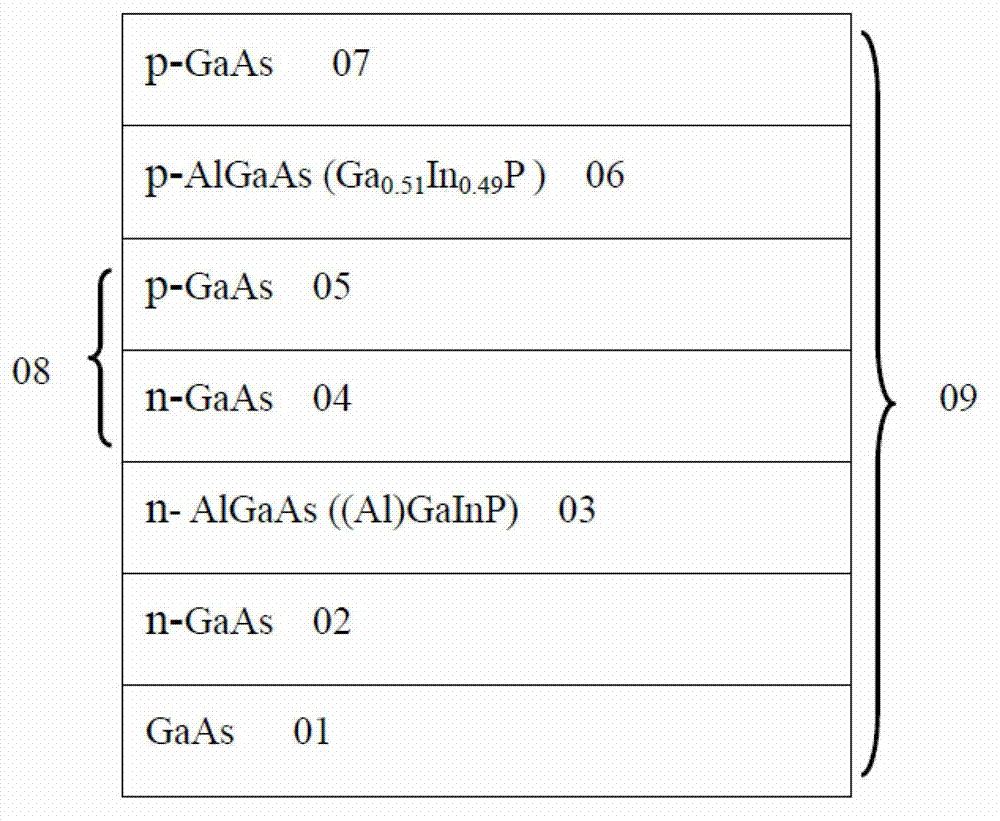

[0040] Specifically, the embodiment of the present invention discloses a laser photovoltaic cell, including an isolation groove that separates the photovoltaic cell into a plurality of battery cells, the battery cells are connected in series, and the inner wall surface of the isolation groove A polyimide layer, a dielectric film layer and a metal light-shielding layer are sequentially formed thereon.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com