Prism sheet and backlight unit using same

A prism sheet, prism technology, applied in prisms, optical components, optics, etc., can solve the problem of reducing frontal brightness, and achieve the effect of improving frontal brightness, reducing light-gathering characteristics, and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

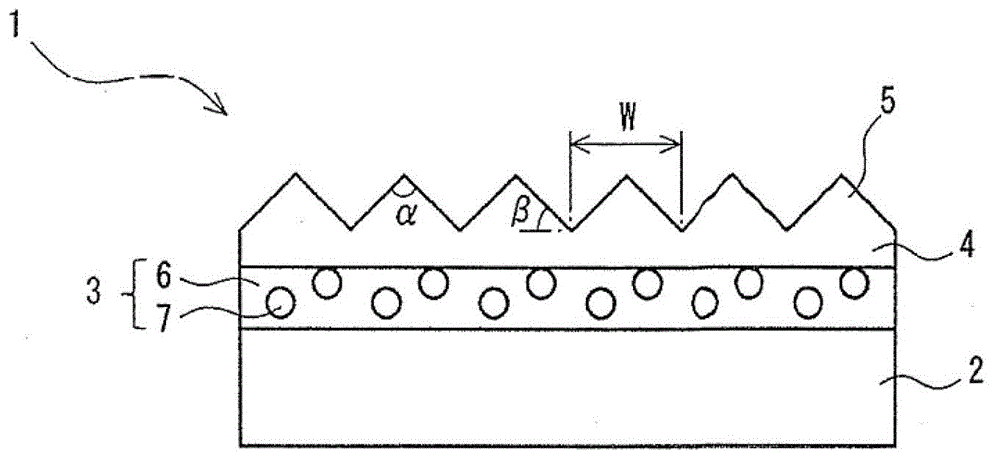

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 The prism sheet 1 has in order from the back side to the front side: a transparent base material layer 2, a microparticle coating layer 3 in which microparticles 7 are dispersed in an adhesive 6, and a sheet-like portion where the surface of the microparticle coating layer 3 is laminated. 4 and a plurality of strip-shaped protruding prism parts 5 .

[0041] Since it is necessary to transmit light, the base material layer 2 may be formed of a transparent, especially colorless and transparent synthetic resin. The synthetic resin used for the base material layer 2 is not particularly limited, and examples thereof include polyethylene terephthalate, polyethylene naphthalate, acrylic resin, polycarbonate, polystyrene, polyolefin, Cellulose acetate, weather-resistant vinyl chloride, active energy ray-curable resin, etc.

[0042] The average thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com