Wire rope extensometer protective device for monitoring tension stress of prestressed reinforcement

A technology of prestressed steel bars and tensile stress, applied in measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems such as loss of function, achieve good protection, small size, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

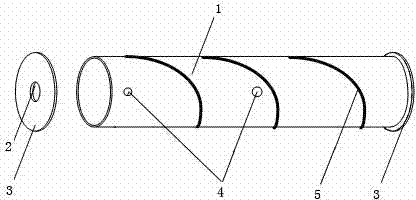

[0019] like figure 1 The present invention is shown as a steel cable gauge protection device for monitoring the tensile stress of prestressed steel bars. Both ports of the columnar hollow pipe body 1 are provided with plugging 3; one end is a fixed port plugging; the other end is a movable The port is blocked, and the plug 3 is provided with a through hole 2, and the outer diameter of the plug 3 is larger than the outer diameter of the pipe body 1. The pipe body 1 is made of round steel pipe, with an outer diameter of 8-12 cm, a length of 0.6-1.0 m, and a thickness of 3-5 mm. The outer surface of the pipe body 1 is welded with a φ6 spiral steel bar 5 to strengthen the anchorage between the pipe body 1 and the concrete. Two through holes 4 are provided at the matching position of the pipe body 1 , one of which is provided in the middle as an oil injection hole, and the other is provided at the edge as a lead-out hole.

Embodiment 2

[0021] The pipe body 1 is made of a square steel pipe, and the outer surface of the pipe body 1 is welded with a φ6 spiral mechanical notch 5 to enhance the anchorage between the pipe body 1 and the concrete. Others are the same as in Embodiment 1, and will not be repeated.

[0022] When using it specifically:

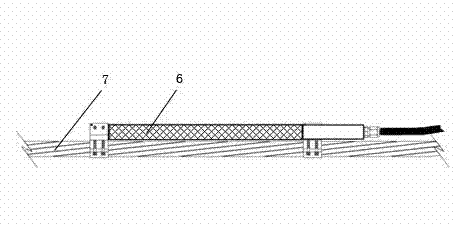

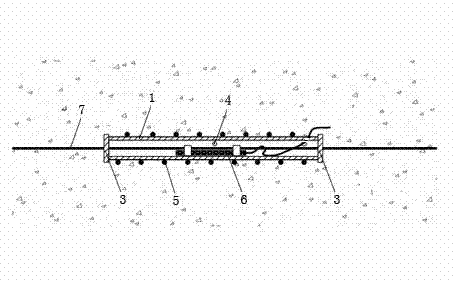

[0023] like figure 2 , image 3 As shown, first the fixed port is blocked and welded to the center of the pipe body 1, and then the prestressed steel bar 7 is penetrated from the through hole 2 blocked by the movable port, and passed out from the through hole 2 blocked by the fixed port. When the prestressed steel bar 7 is 0.6~1m away from the design position, stop threading the bar. At this time, the outer cladding of the prestressed steel bar 7 is peeled, and the steel cable gauge 6 is installed according to the design position of the steel cable gauge. Then the prestressed steel bar 7 and the steel cable meter 6 are inserted into the suitable position in the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com