Socket and spigot type pipeline connector with anchoring structure

A pipe interface, socket-type technology, applied in the direction of pipes/pipe joints/fittings, through components, mechanical equipment, etc., can solve the problems of anchor teeth breakage, inconvenient optimization design, limiting pipeline transportation capacity, etc., to reduce meshing. The effect of tooth fracture, improving anchoring reliability, and safe anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

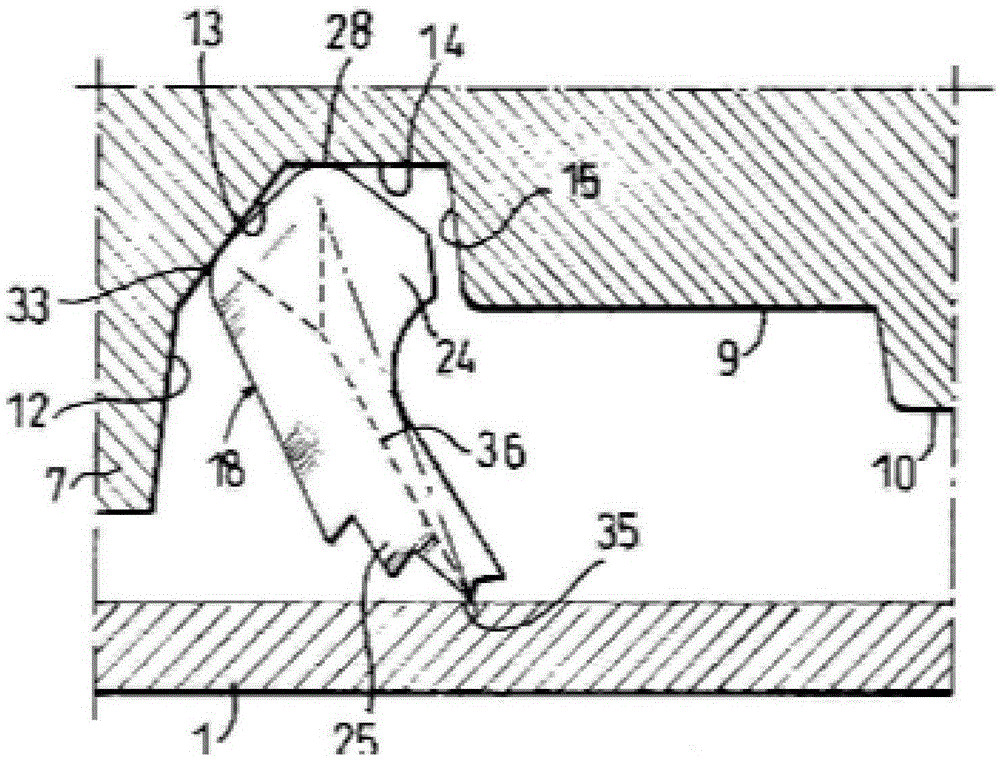

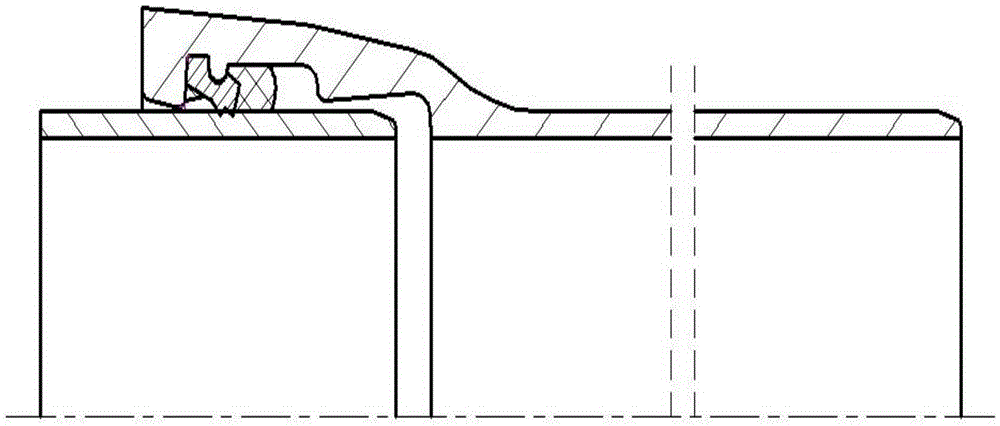

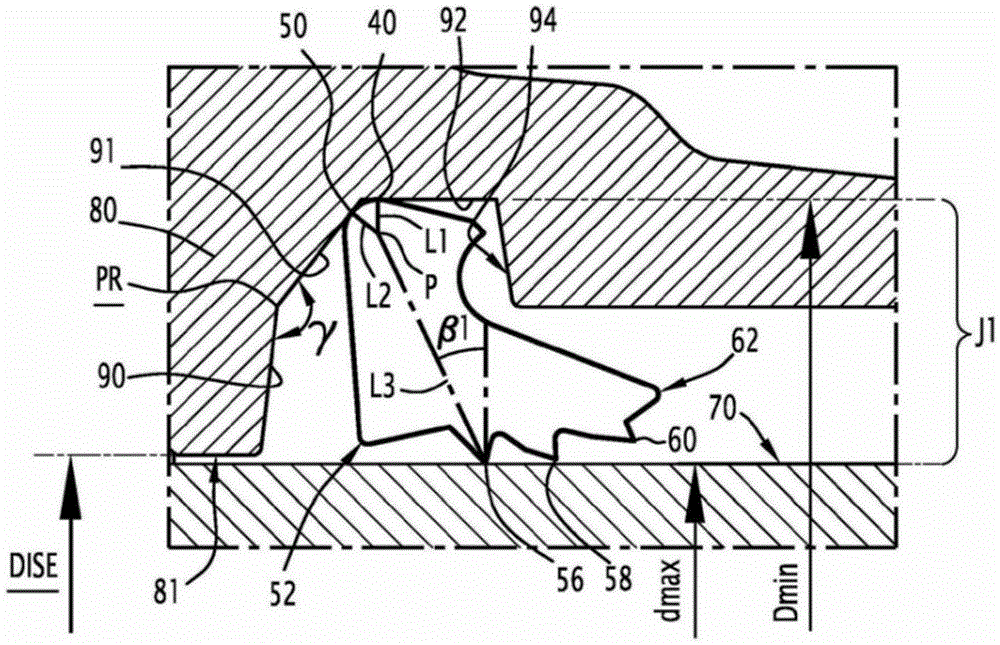

[0064] combine Figure 2-5 As shown, the socket-and-socket pipe connection with anchoring structure of the present invention includes a socket 67, a socket 66, a seal 65 between the socket 67 and the socket 66 for sealing and locking the pipe connection, wherein the socket 67 and The sockets 66 belong to two pipes respectively, and the two pipes are plugged in through the sockets and the sockets.

[0065] The socket 67 includes an annular groove 5 which is sequentially connected and defined by the first annular vertical wall 1, the tapered wall 2, the cylindrical inner wall 3 and the second annular vertical wall 4. The annular groove 5 is used to support the sealing member 65, and the sealing member 65 includes an elastic material ring 69 and a plurality of anchors 68 embedded therein, and a plurality of anchors 68 can be annular and embedded in the elastic material ring 69 at equal intervals. Of course, a plurality of anchors 68 can also be annular and not Elastomeric rings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com