A brass solid spherical roller bearing cage and its forming method

A technology of self-aligning roller bearings and cages, which is applied in the direction of roller bearings, bearings, bearing components, etc., and can solve the problem of cracking of the inner ring rigid rib oil groove, incomplete axial positioning of rollers, and the inability to apply reinforced type Design and other issues, to achieve the effect of long service life, good balance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

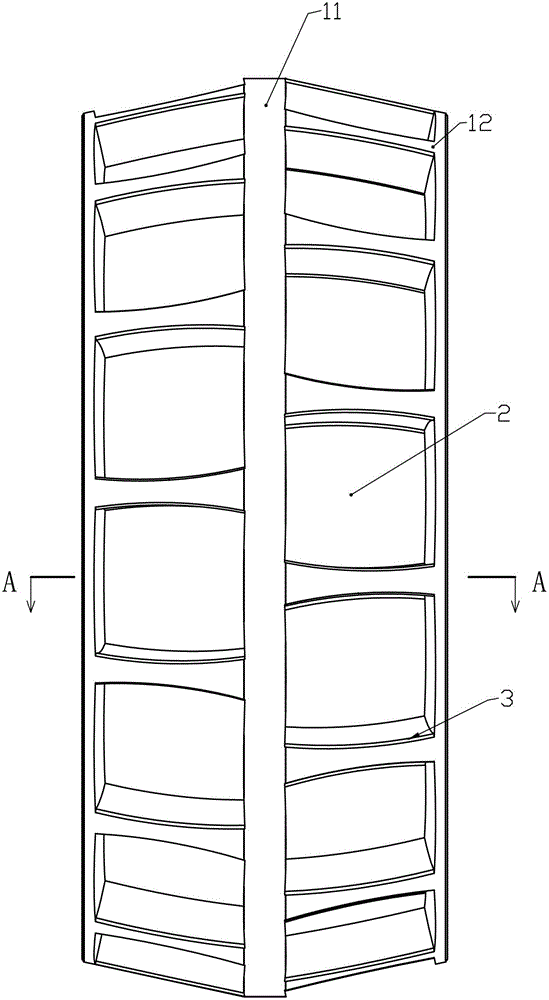

[0026] like Figure 1 to Figure 3 as shown,

[0027] A brass solid spherical roller bearing cage, including a cage body 1. The cage body is integrally formed by machining. First, a brass blank is prepared, and then its inner and outer surfaces are machined for the first time. An intermediate ring 11 with a thick middle and thinner sides and an inner conical cylinder 12. The inner and outer surfaces of the intermediate ring are annular surfaces concentric with the inner ring of the bearing, which is convenient for machining. The inner and outer surfaces of the inner tapered cylinder are parallel to each other and parallel to the axis of rotation of the roller. Then, two rows of roller installation holes 2 are formed on the brass blank by CNC milling process. The roller installation holes 2 are evenly distributed in the circumferential direction of the cage body and the axis normals of all roller installation holes intersect at one point. The roller installation In the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com