Diesel engine back pressure control valve assembly

A technology for controlling valve assemblies and diesel engines, which is applied in engine control, mechanical equipment, machines/engines, etc. It can solve the problems of poor protection ability, high stress, and poor reliability, and achieve strong environmental resistance, good rigidity, and guarantee long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

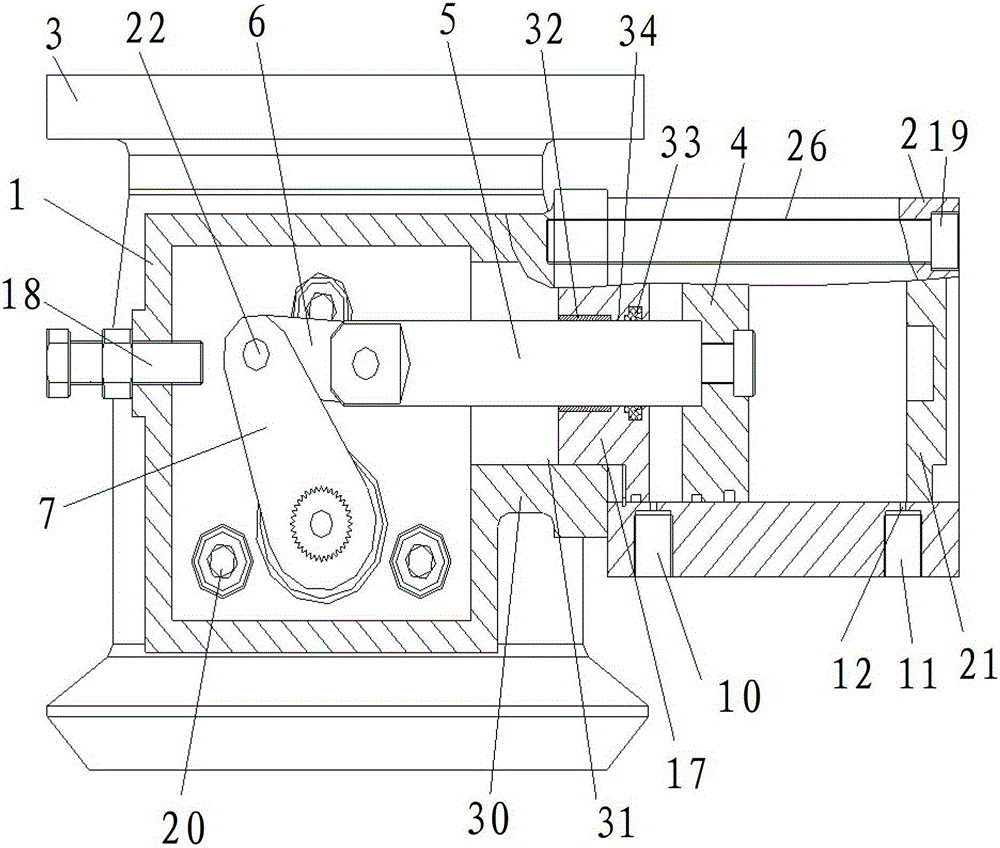

[0030] Attached below Figure 1-7 Embodiments of the present invention are described.

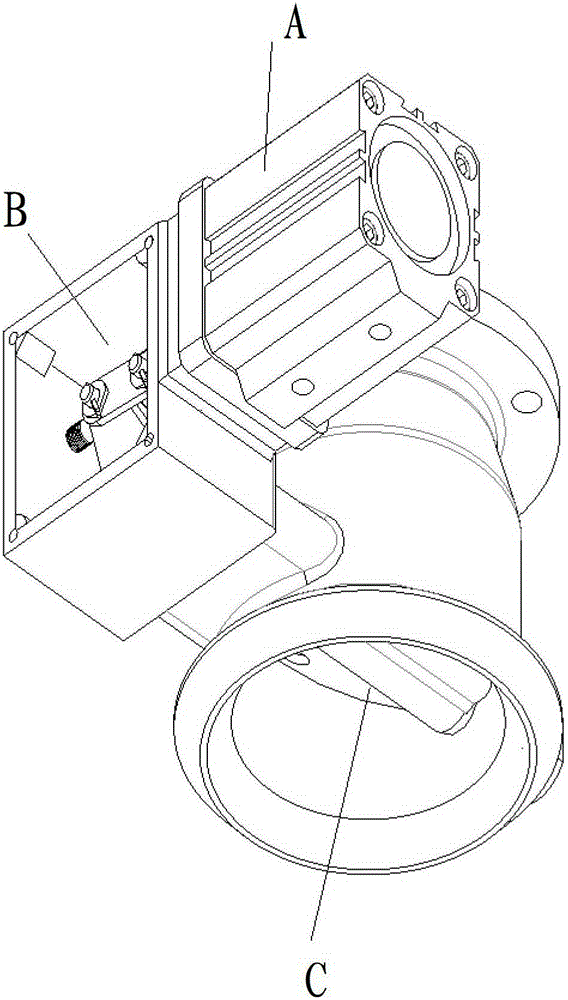

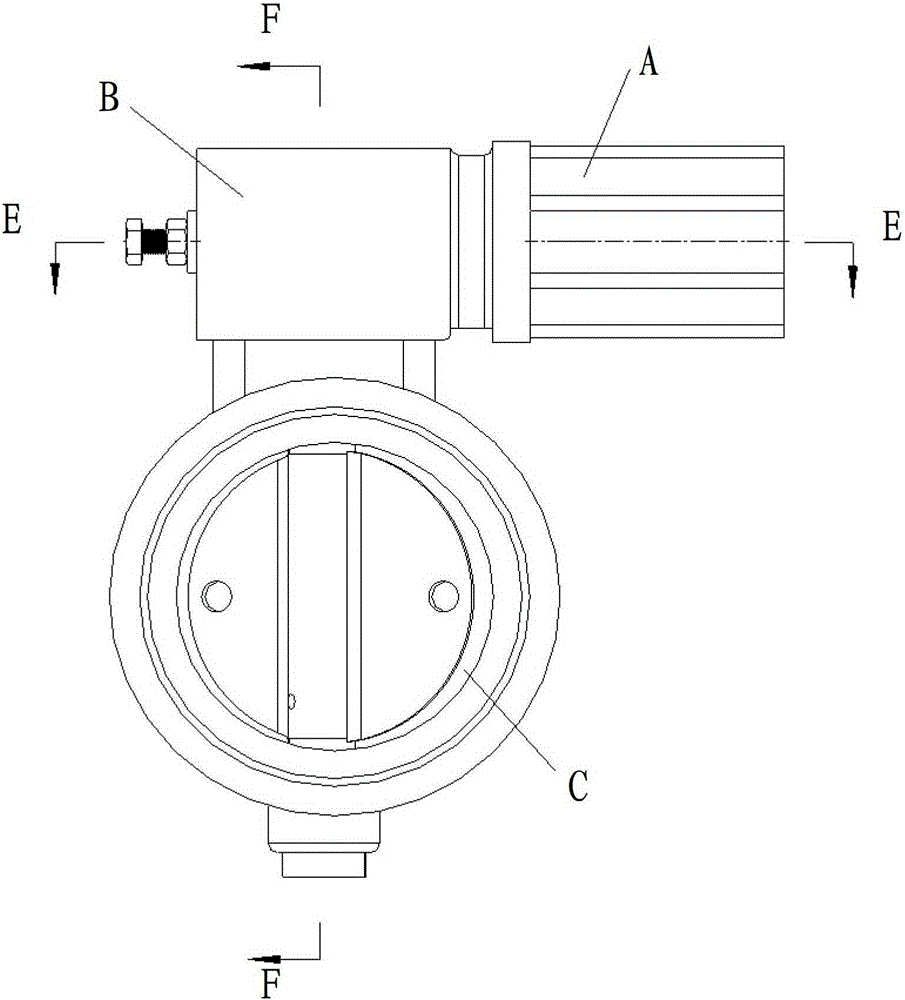

[0031] Diesel engine back pressure control valve assembly, the assembly is a unit combination structure, including drive unit A, transmission unit B and action unit C, one end of the cylinder body 2 of the drive unit A and the transmission housing 1 side of the transmission unit B The bottom of the transmission housing 1 of the transmission unit B and the top of the valve body 3 of the action unit C are connected as a whole through the seam seal, and the driving unit A is driven by the transmission unit B. The unit C is twisted to cover or open the air flow channel of the valve body 3 . The drive unit A, the transmission unit B and the action unit C have mutual installation positioning references, which can be processed separately and assembled according to each other's positioning. After the three are assembled, they are completely in a closed structure. Sand, dust, splash water, and rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com