Nickel-plated carbon fiber shielding paper and preparation method thereof

A technology of nickel-plated carbon fiber and bleached wood pulp, which is applied in the fields of shielding technology, papermaking and composite materials, can solve the problems of not involving waterproof and fireproof, limited application scope, decreased mechanical properties, etc., and achieves good electromagnetic shielding effect and comprehensive performance. , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

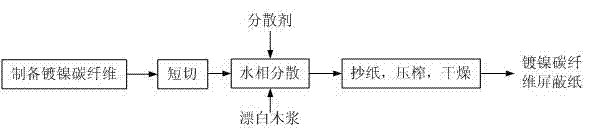

[0027] A preparation method of nickel-plated carbon fiber shielding paper, comprising the following steps:

[0028] A. Preparation of nickel-plated carbon fibers. The nickel-plated carbon fiber is formed by electroplating nickel on the surface of the carbon fiber. The process flow of electroplating nickel is carbon fiber→surface degumming→water washing→electroplating→water washing→drying. Burn for 5 minutes to remove the organic binder on the carbon fiber surface. The current density for electroplating is 100 mA / dm 2 , electroplating time is 6 min, pH value is 4, nickel sulfate 270g / L, boric acid 40g / L, nickel chloride 70g / L are used. At the same time, 0.1g / L sodium dodecylsulfonate should be added, the pH value is 3-4, the temperature is 25°C, and the thickness of the nickel coating is 0.4μm.

[0029] B. Prepare bleached wood pulp. The beating degree of bleached wood pulp is 38°SR, the length of the nickel-plated carbon fiber after chopping is 2-6mm, and the dispersant is ...

Embodiment 2

[0033] A preparation method of nickel-plated carbon fiber shielding paper, comprising the following steps:

[0034] A. Preparation of nickel-plated carbon fibers. The nickel-plated carbon fiber is formed by electroplating nickel on the surface of the carbon fiber. The process flow of electroplating nickel is carbon fiber→surface degumming→water washing→electroplating→water washing→drying. Burn for 5 minutes to remove the organic binder on the carbon fiber surface. The current density for electroplating is 100 mA / dm 2 , the plating time is 8 min, the pH value is 4, nickel sulfate is 280g / L, boric acid is 45g / L, and nickel chloride is 70g / L. At the same time, 0.1 g / L of sodium dodecylsulfonate was added, the pH value was 4, the temperature was 25° C., and the thickness of the nickel coating was 0.5 μm.

[0035] B. Prepare bleached wood pulp, the beating degree of bleached wood pulp is 38°SR, the length of the nickel-plated carbon fiber after chopping is 2 ~ 6mm, the dispersan...

Embodiment 3

[0039] A preparation method of nickel-plated carbon fiber shielding paper, comprising the following steps:

[0040] A. Preparation of nickel-plated carbon fibers. The nickel-plated carbon fiber is formed by electroplating nickel on the surface of the carbon fiber. The process flow of electroplating nickel is carbon fiber→surface degumming→water washing→electroplating→water washing→drying. Burn for 5 minutes to remove the organic binder on the carbon fiber surface. The current density for electroplating is 100 mA / dm 2, plating time 8 min, pH value 4, use nickel sulfate 270g / L, boric acid 40g / L, nickel chloride 70g / L, add sodium dodecylsulfonate 0.1g / L at the same time, pH value 4, temperature 25 ℃, nickel coating thickness is 0.5μm

[0041] B. Prepare bleached wood pulp. The beating degree of bleached wood pulp is 35°SR. The length of the nickel-plated carbon fiber after chopping is 2-6 mm. The dispersant is APAM, which is added in an amount of 1% volume fraction. The nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com