Nano-silver PVC (polyvinyl chloride) lamellar membrane and preparation method thereof

A technology of nano-silver and sheet film, which is applied in the field of antibacterial materials, can solve the problem of no antibacterial effect of PVC sheet film, achieve good sterilization effect, strong practicability, and increase practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

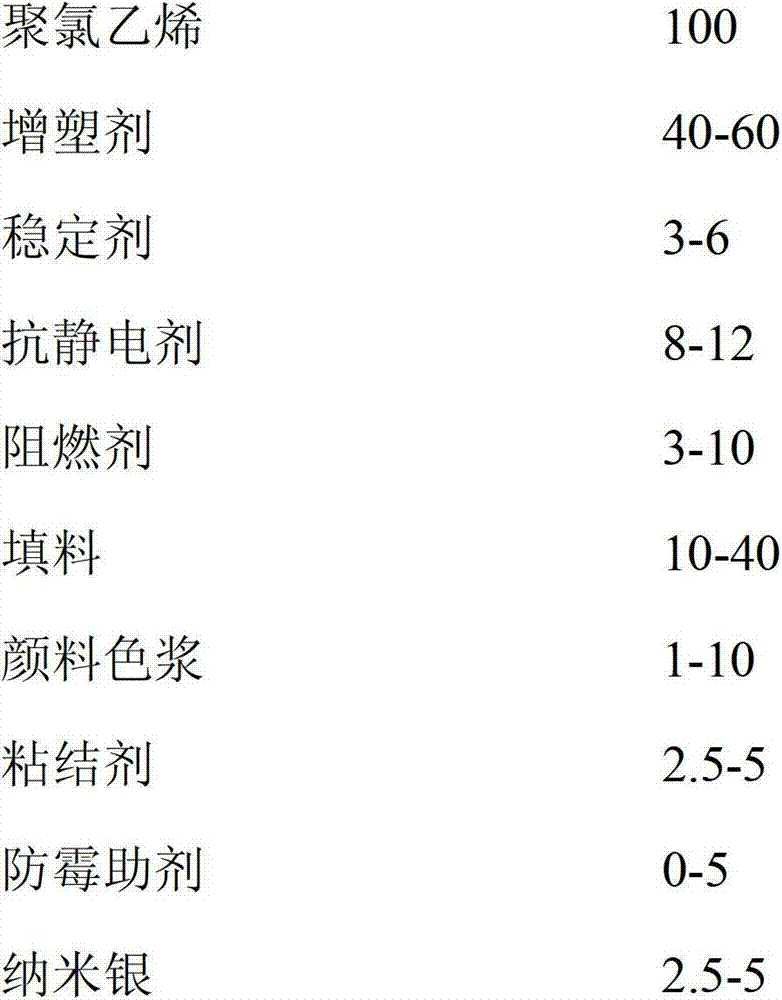

[0031] We weigh each component of the following parts by weight:

[0032]

[0033] Then do the following:

[0034] After mixing the above-mentioned components weighed, they are kneaded in a high-speed mixer through a conveying system;

[0035] After kneading, the components are sent to an internal mixer (closed rubber mixer) for internal mixing;

[0036] The components after internal mixing are transported into the open mixer (open rubber mixer) for open mixing;

[0037] After the refining, the components enter the planetary extruder and then extruded by the planetary system;

[0038] The components of the planetary extrusion are calendered into a sheet film through a calender

[0039] Extraction, cooling, and winding of the calendered film to obtain the finished product 1

Embodiment 2

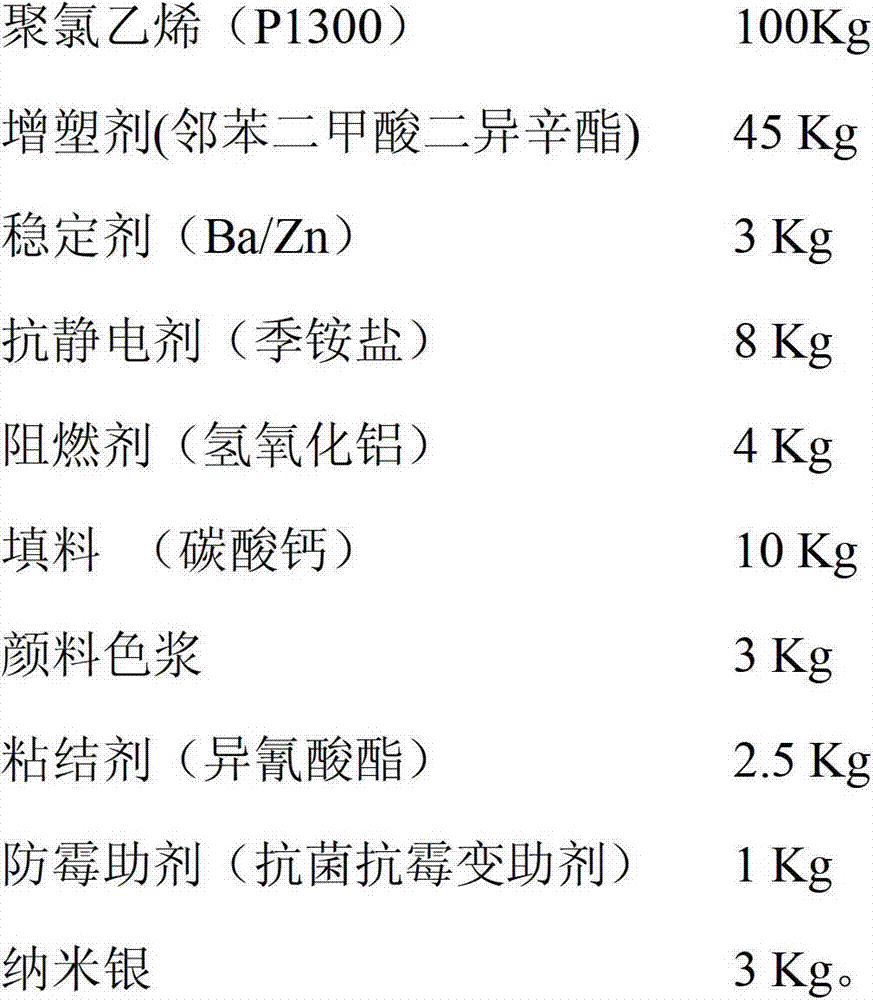

[0041] We weigh each component of the following parts by weight:

[0042]

[0043] Then we carry out operation with the operation step in embodiment 1 to above-mentioned each component, obtain finished product 2.

Embodiment 3

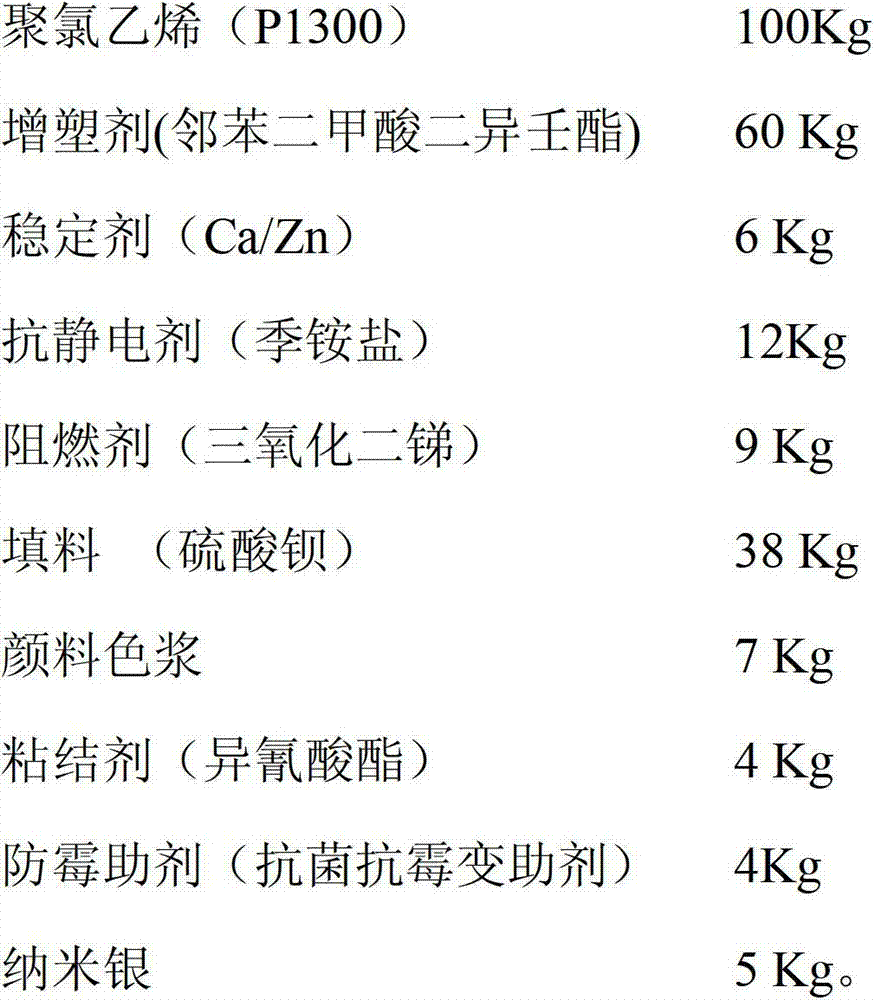

[0045] We weigh each component of the following parts by weight:

[0046]

[0047]

[0048] Then we carry out operation with the operation step among the embodiment 1 to above-mentioned each component, and its difference is, in the embodiment 3, also comprise composite section, it comprises the following steps:

[0049] a. Select fabric as the base material for unwinding (according to actual needs, it can also be other base materials);

[0050] b. Then preheat the fabric substrate;

[0051] c. After preheating, introduce the base cloth for compounding;

[0052] d. At this time, it is pasted with the components calendered in step 5;

[0053] e. Then continue to operate with step 6 to carry out extraction, cooling, and winding to obtain the finished product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com