Novel technique for producing methyl acetate

A technology of methyl acetate and new process is applied in the new process field of continuous production of methyl acetate, can solve the problems of high energy consumption, poor extraction effect, large amount of extraction agent, etc., and achieves the effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

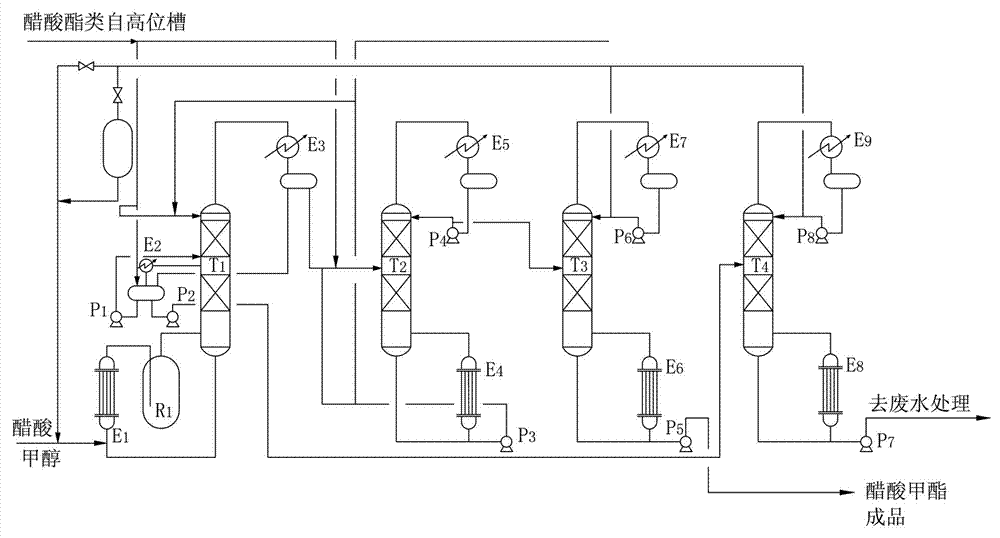

[0030] The new process for the production of methyl acetate described in Example 1, firstly carries out esterification reaction rectification, then carries out the removal of acetic esters, finally carries out methyl acetate rectification, and simultaneously carries out wastewater treatment to obtain methyl acetate finished product And by-products methanol and acetate, recycling by-products backflow continue to produce methyl acetate. The process includes the following steps:

[0031] (1) Esterification reaction rectification: the raw materials acetic acid and methanol are fed into the esterification tower reaction through the esterification reboiler at a molar ratio of 1:1.5; part of the products extracted from the middle of the esterification tower enter the esterification phase separator for separation Acetate esters and waste water are obtained by layering. The layered acetates are returned to the esterification tower, and the waste water enters the wastewater recovery tower;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com