Material transfer unit for automobile production lines

A technology of automobile production line and equipment, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of prone to errors and omissions, mixed placement, and failure to meet the production requirements of batch assembly lines, so as to reduce storage, improve error prevention and protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples illustrate the technical solutions of the present invention in detail. It should be understood that the following embodiments can only be understood as explanations and descriptions of the technical solutions of the present invention and cannot be construed as limitations on the technical solutions of the present invention.

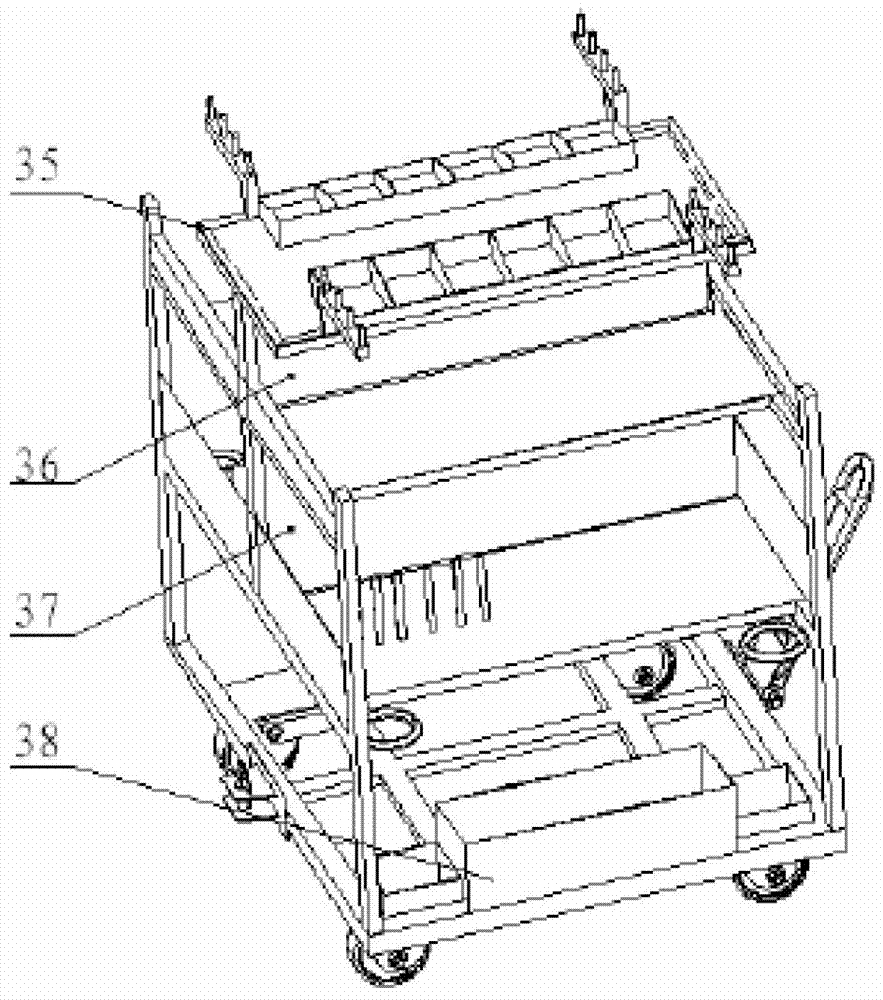

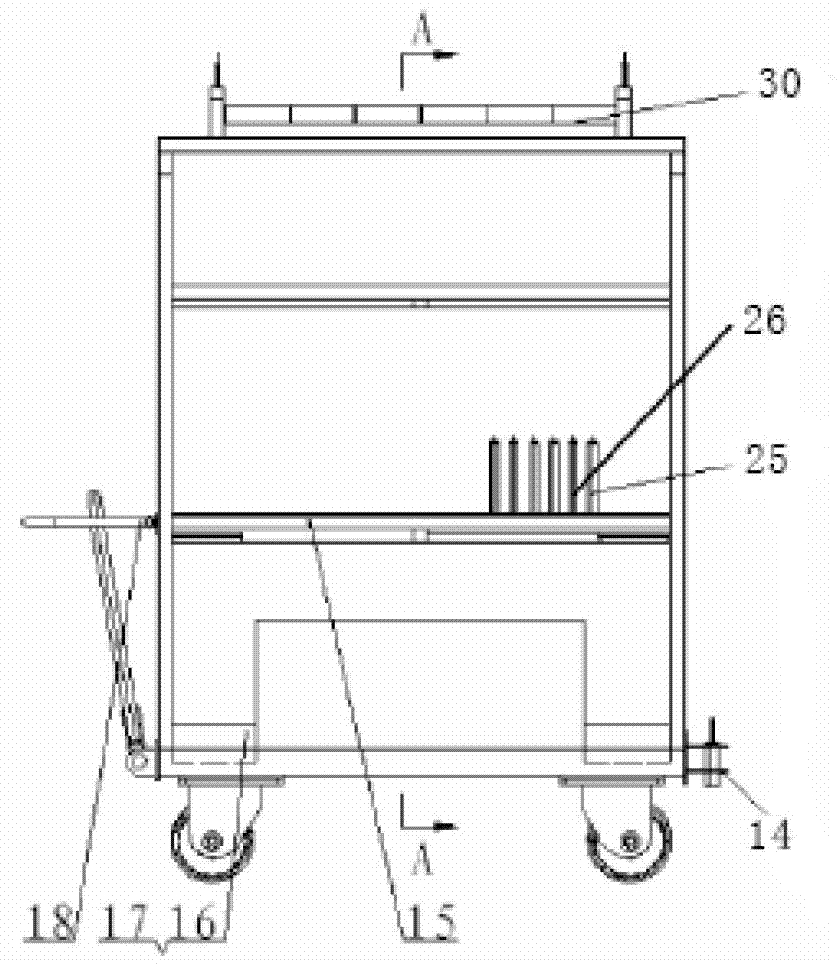

[0021] figure 1 This is a schematic diagram of the structure of the material transfer equipment for the automobile production line of the present invention; the figure shows the large material box 38 located in the bottom frame, the lower middle partition 37 and the upper middle partition 36 arranged on the second layer frame and the third layer frame, The uppermost frame 35.

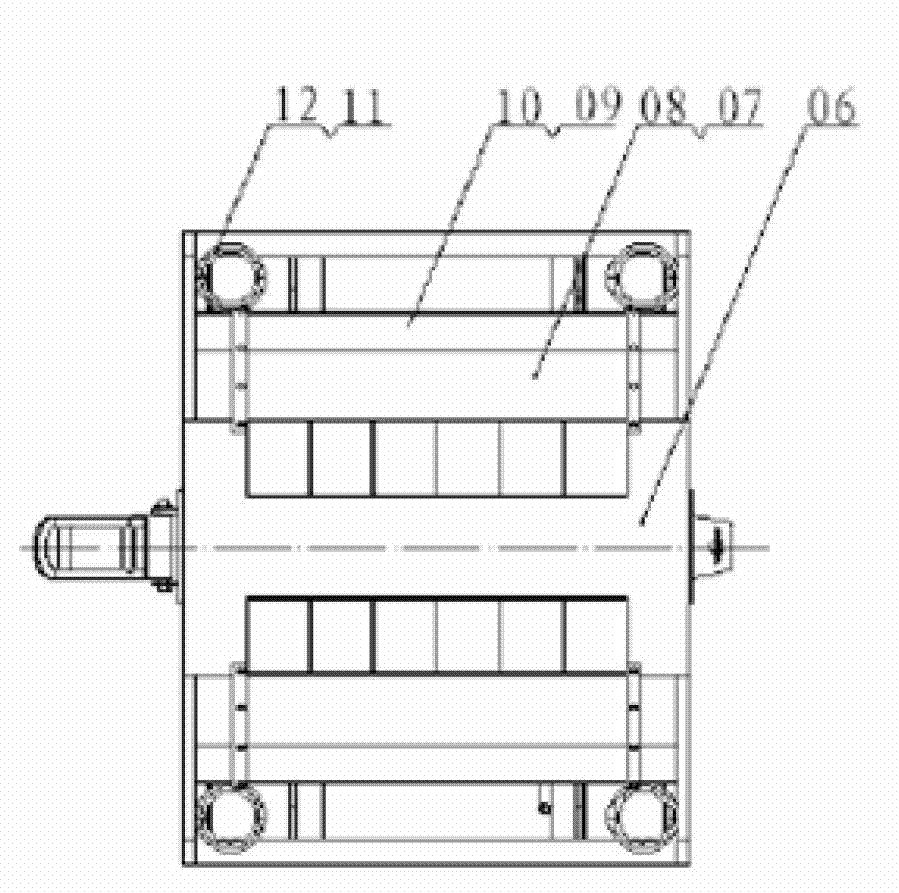

[0022] figure 2 for figure 1 The top view of the transfer equipment, which shows the first layer 6, the second layer 7 and the third layer 9 between two adjacent frames; the second layer 7 is provided with the second layer The board protection pad 8 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com