A digital twin system for a production line

A production line and twinning technology, applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of lack of effective use of actual data, low technical difficulty in installation and deployment, and deviation of simulation results, so as to reduce manual sending instructions , improve the ability to prevent mistakes, and reduce the effect of layout costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

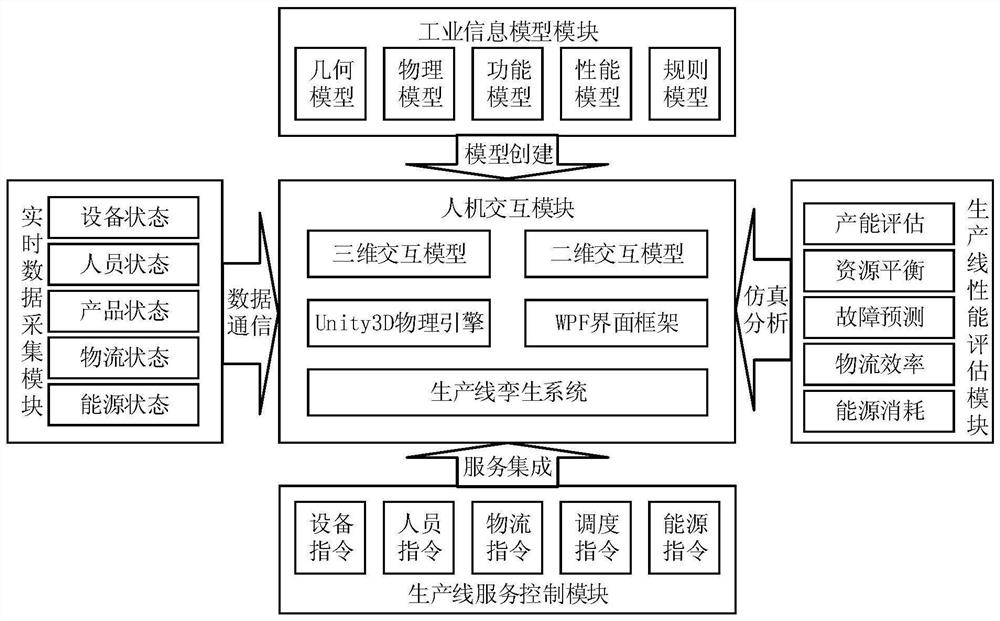

[0096] Refer below figure 1 , the principle and working process of the present invention will be described in detail through an embodiment: the digital twin production line in this embodiment includes 1 line edge warehouse and 2 processing units. Among them, the line side warehouse is composed of a finished product warehouse and 3 semi-finished product warehouses; one processing unit is composed of a three-degree-of-freedom manipulator, a return-shaped conveyor belt and two machine tools, and the other processing unit is composed of a six-degree-of-freedom manipulator Composed of manipulator and 3 machine tools. It should be noted that the structural composition of the workshop production line is not limited to this, and may also have other structural forms.

[0097] Such as figure 1 As shown, the production line digital twin system in this embodiment specifically includes the following steps:

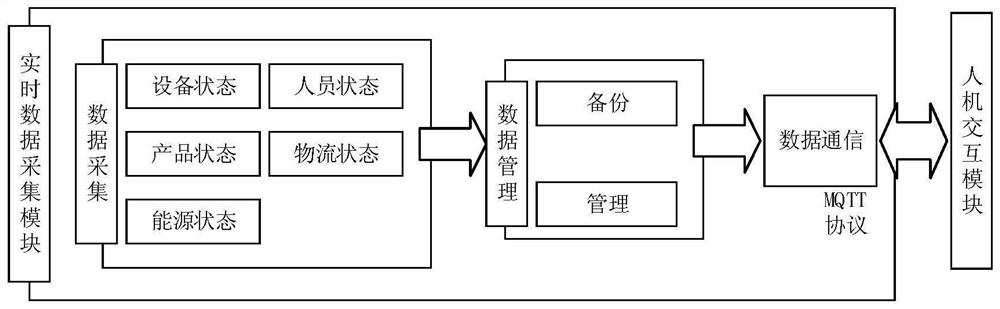

[0098] The real-time data acquisition module uses a variety of sensors and indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com