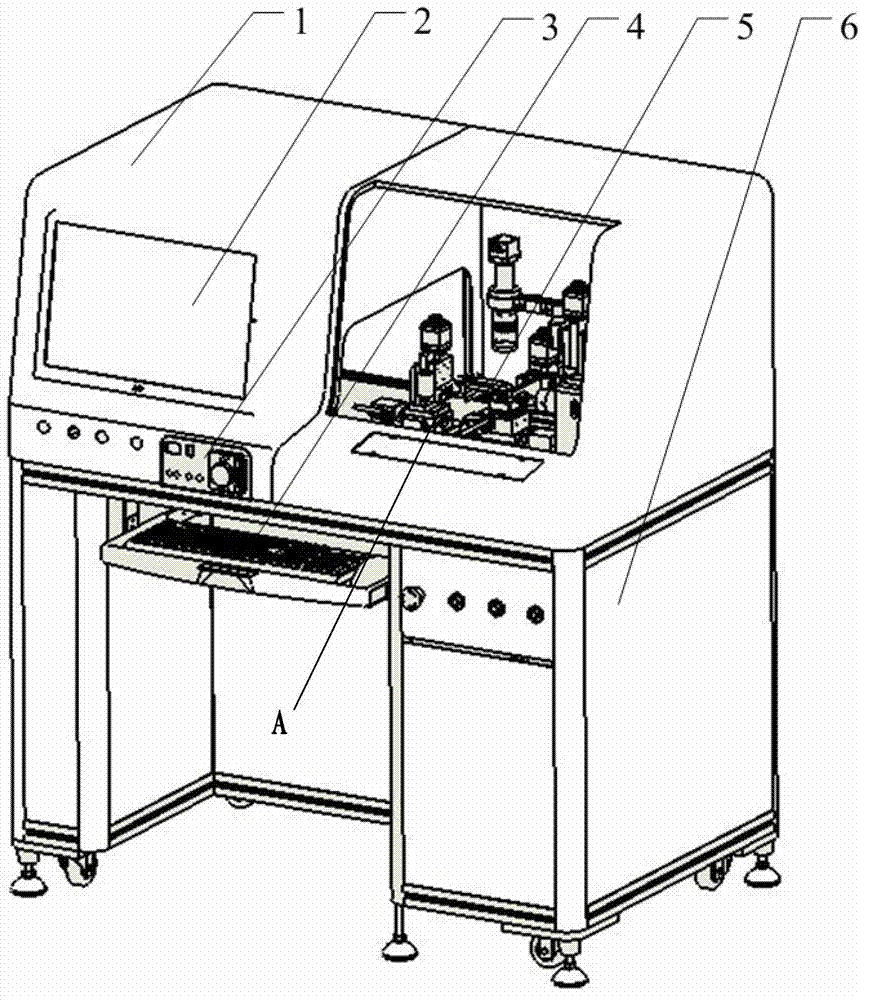

Thin-wall structural member automatic arranging and positioning machine and arranging and positioning method before finish machining

A technology of thin-walled structural parts and automatic arrangement, applied in metal processing, metal processing equipment, manufacturing tools, etc., to reduce labor intensity, solve the inevitable introduction of processing and assembly stress, and reduce production and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

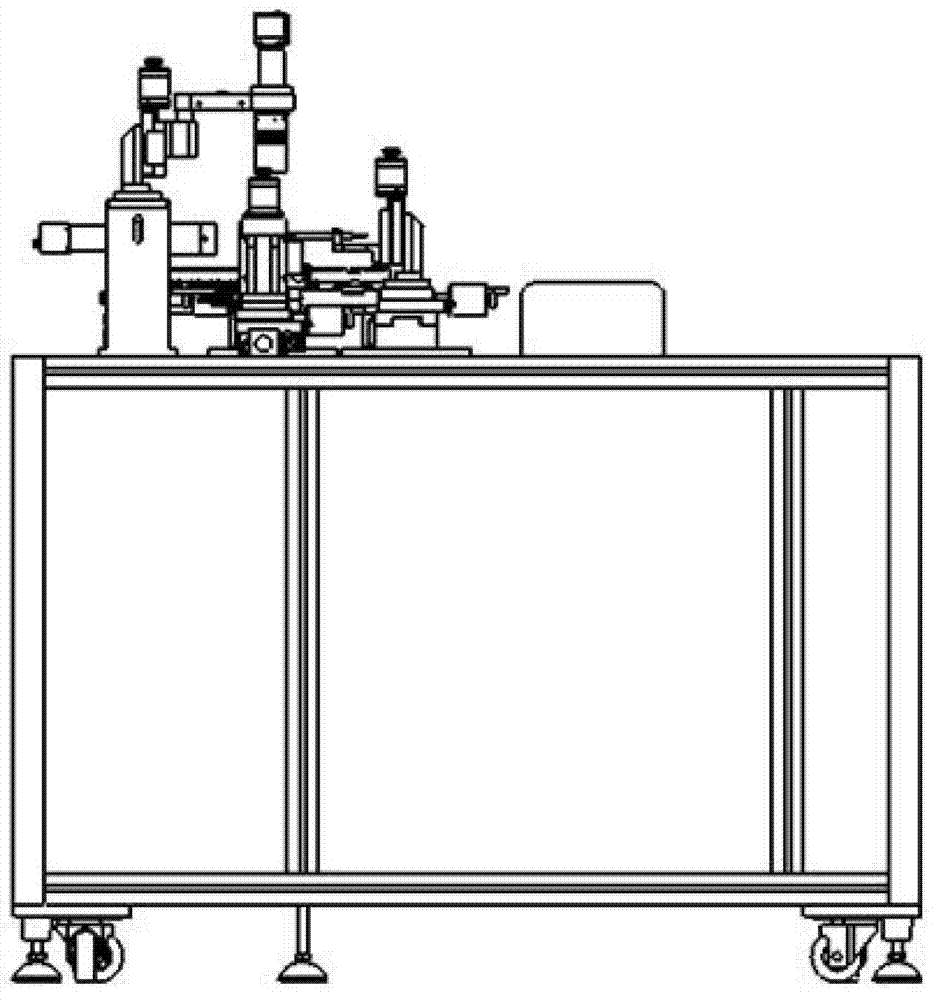

[0040] Since the processing technology of micro and small parts has reached a certain level of development, the development of the corresponding assembly technology is still relatively slow. The qualified rate of products is greatly restricted, and the requirements for the skills of operators are very high. Not only is the operation process complicated and inefficient, but it will also cause problems and deficiencies such as subsequent processing and assembly stress.

[0041]Aiming at the deficiencies in the prior art, the present invention proposes an automatic alignment and positioning machine and an alignment and positioning method for thin-walled structural parts before finishing. The cost of production and assembly can greatly reduce the labor intensity of operators, and at the same time, it can effectively solve the problem of inevitably introducing processing and assembly stress in manual assembly.

[0042] The technical solutions of the present invention will be clearl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com