Movable type suspension crane rocker arm drilling machine

A technology of radial drilling machine and cantilever crane, which is applied in the direction of boring/drilling, drilling/drilling equipment, large fixed members, etc. It can solve the problems of incompatibility, etc., and achieve convenient observation, small footprint, and clear solution sound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: ZQF3732, ZF3725, ZW3732, ZW3725 mobile cantilever hanging rocker drill with 1.5kW of main motors are examples:

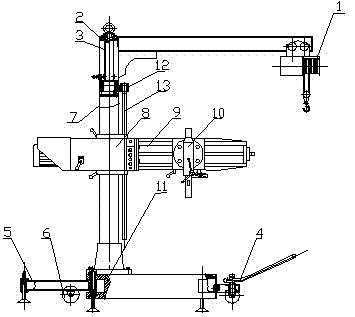

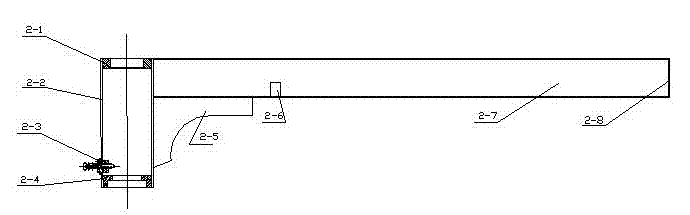

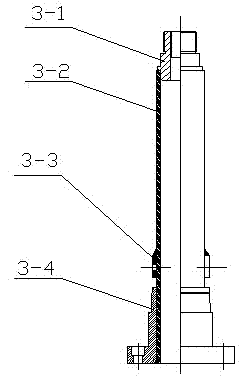

[0024] like figure 1 — 5 Shows, the new cantilever hanging ranging electric gourd on the basis of the rocker drilling machine 1. Gongcoura rocker assembly 2. Ten shaft 3, traction device 4. Auxiliary supporting legs 5 and rolling wheel 6, old rocker arm, old rocker arm armsThe original base components, column parts, diamond machine gearbox 8, horizontal arm 9, main axis box 10, but the structure of the base component 11, the structure of the base component 7 is different from the structure of the base 11 and the column 7 in this embodiment.EssenceNewly added cantilever hanging electric gourd 1. Gongcoullac rocker assembly 2. The image of the shaft 3 is to wear a hat project for drilling machine; traction device 4. Auxiliary supporting legs 5 and rolling wheel 6 are the boots of the drilling machine.; Pillar 7 has suffered a lot of bending moment, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com