Unsupported hydrodemetallization catalyst and preparation method thereof

A hydrodemetallization and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve complex temperature control, poor product stability, and hole expansion Poor effect and other problems, to achieve the effect of reducing diffusion limitation, improving mass transfer and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

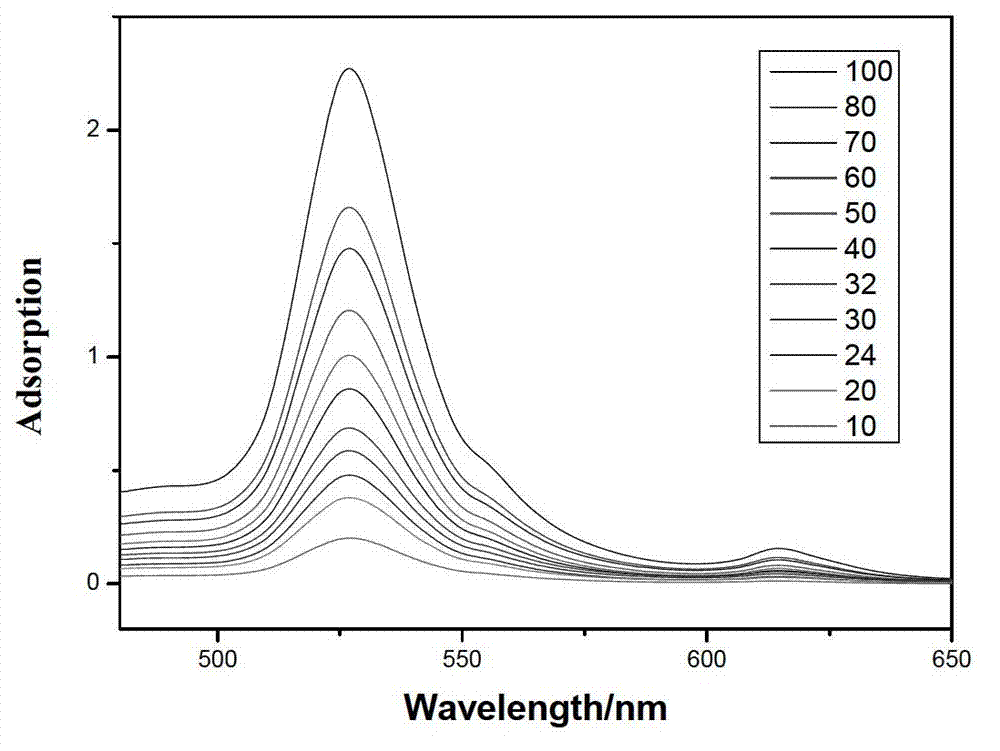

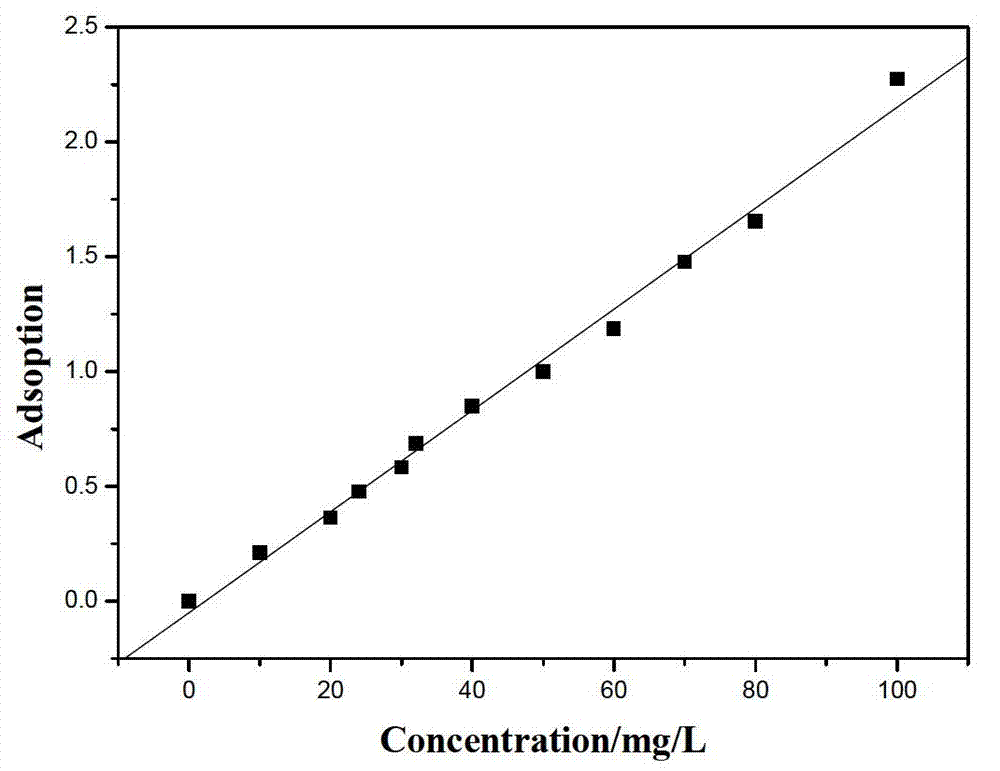

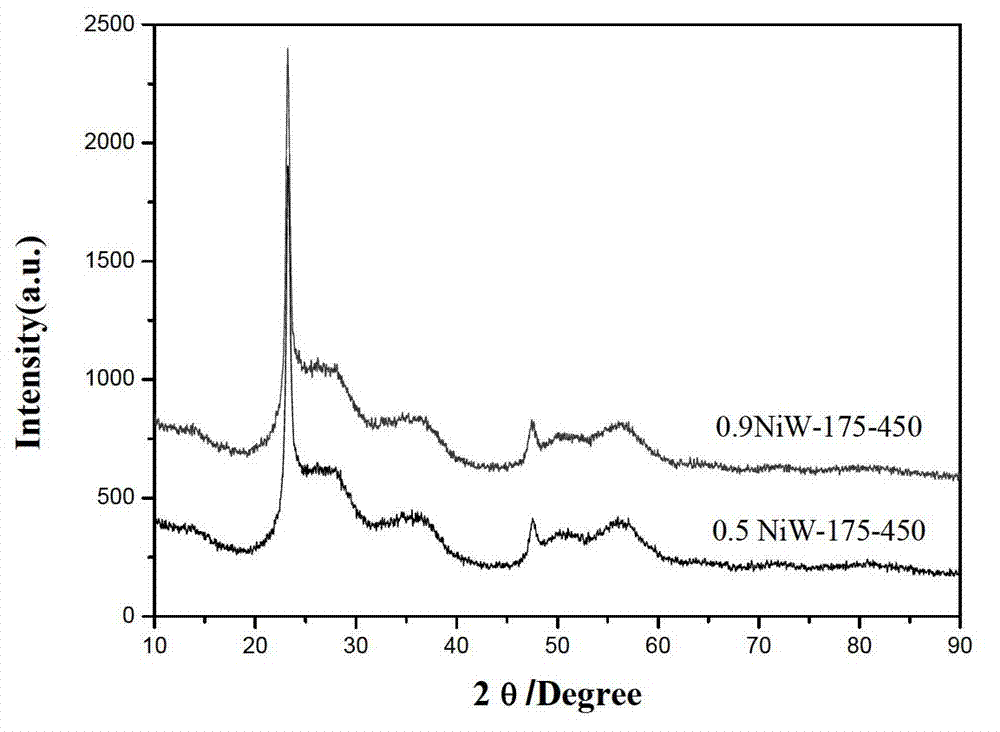

[0031] Embodiment 10.5NiW-175-450 catalyst

[0032] Weigh 3.1g of nickel nitrate hexahydrate and 6.0g of ammonium metatungstate respectively, add 30mL of deionized water, and stir until they are completely dissolved. After 30 min, the two solutions were mixed evenly, and after stirring for 1 h, they were transferred to a 100 ml hydrothermal synthesis kettle, and subjected to hydrothermal action at a temperature of 175° C. for 48 h. Then directly cool to room temperature with cold water, wash 3 times with deionized water, and dry at 100° C. for 12 h to obtain a catalyst precursor. Then it is placed in a muffle furnace and calcined at 450°C for 4h. The prepared catalyst sample is recorded as 0.5NiW-175-450, the average pore diameter of the catalyst is 13-20nm, the pore volume is 0.2-0.3ml / g, and the specific surface area It is 50-70m2 / g.

[0033] The performance of the catalyst was evaluated by the hydrodemetallation reaction of nickel porphyrin. Get 5,10,15,20-tetramethyl-21...

Embodiment 20

[0037] Embodiment 20.7NiW-175-450 catalyst

[0038] The preparation method of the catalyst is the same as in Example 1, but the addition of nickel nitrate hexahydrate is 4.4g, and the other compositions are unchanged, and the 0.7NiW-175-450 catalyst is prepared, and the performance evaluation and product analysis of the catalyst to the hydrodemetallization catalytic reaction Condition is the same as embodiment 1, and the results are shown in Table 1.

Embodiment 30

[0039] Embodiment 30.9NiW-175-450 catalyst

[0040] The preparation method of the catalyst is the same as in Example 1, but the addition of nickel nitrate hexahydrate is 5.6g, and the other compositions are constant, and the 0.9NiW-175-450 catalyst is prepared, and the performance evaluation and product analysis of the catalyst to the hydrodemetallization catalytic reaction Condition is the same as embodiment 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com