Self-propelled green bean combined harvester

A combine harvester and self-propelled technology, which is applied in the direction of harvesters, cutters, crop processors, etc., can solve the problems of high labor intensity, need for a lot of manpower, and high loss rate, so as to improve work efficiency, improve bean quality, Appropriate clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

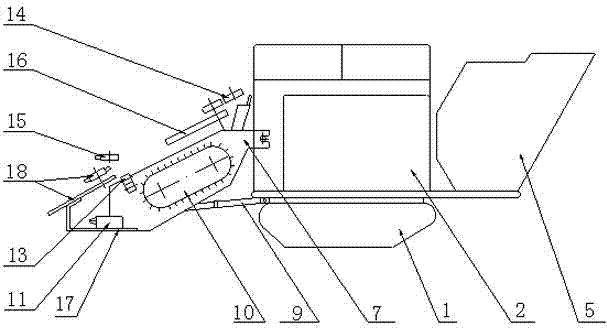

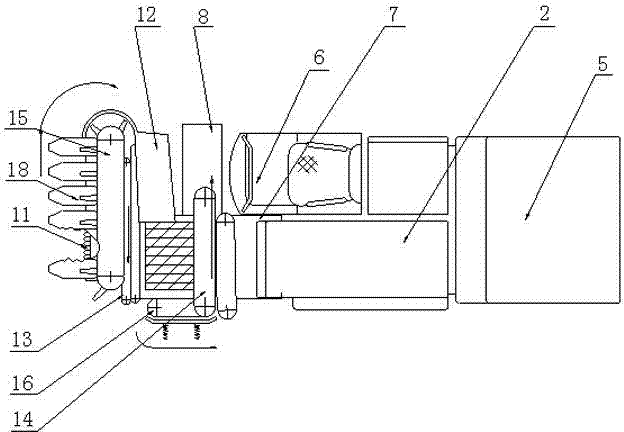

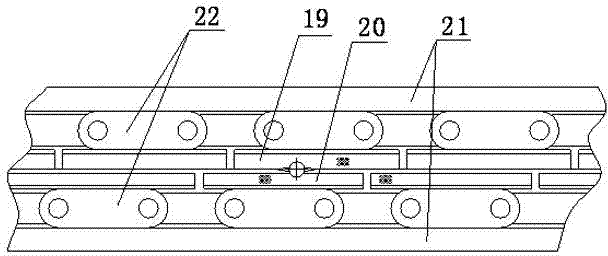

[0030] Such as Figure 1-9 As shown, the self-propelled green soybean combine harvester of the present invention includes a chassis 1, a sorting and cleaning mechanism 2, a harvesting platform 3, a straw pulverizer 4 and a self-unloading storage bin 5, and a power mechanism and a driving platform are installed on the upper end of the chassis 1. 6 and the sorting and cleaning mechanism 2, the lower end of the chassis 1 is equipped with a traveling mechanism, the lower end of the chassis 1 is equipped with a traveling mechanism, the tail end of the chassis 1 is connected with a self-unloading storage bin 5, and the front end of the sorting and cleaning mechanism 2 is hinged with a harvesting platform 7, The front end of the harvesting platform 7 is provided with a cutting and conveying mechanism, and the inside of the harvesting platform 7 is provided with a multi-indented toothed belt picker 10. An adjustment cylinder 9 is connected between the harvesting platform 7 and the sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com