Control circuit of energy discharging of large magnetic moment magnetorquer

A magnetic torque device and discharge circuit technology, which is applied in the direction of electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve the problem of driving circuit operating voltage increase, power supply voltage increase, charging, etc. problem, to achieve the effect of simple and reliable circuit structure, improved service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

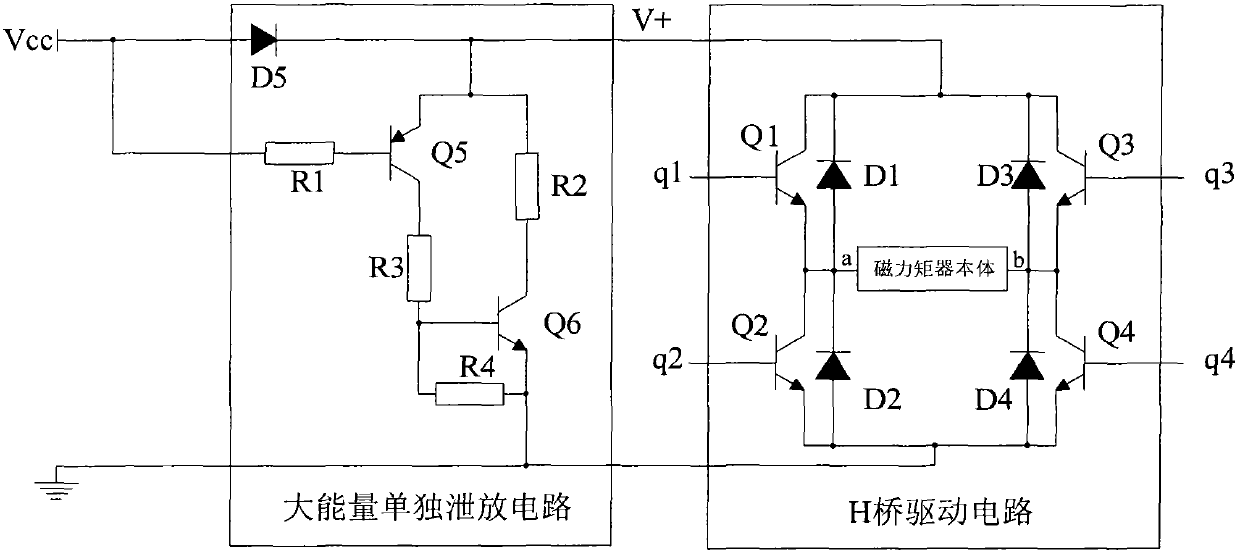

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

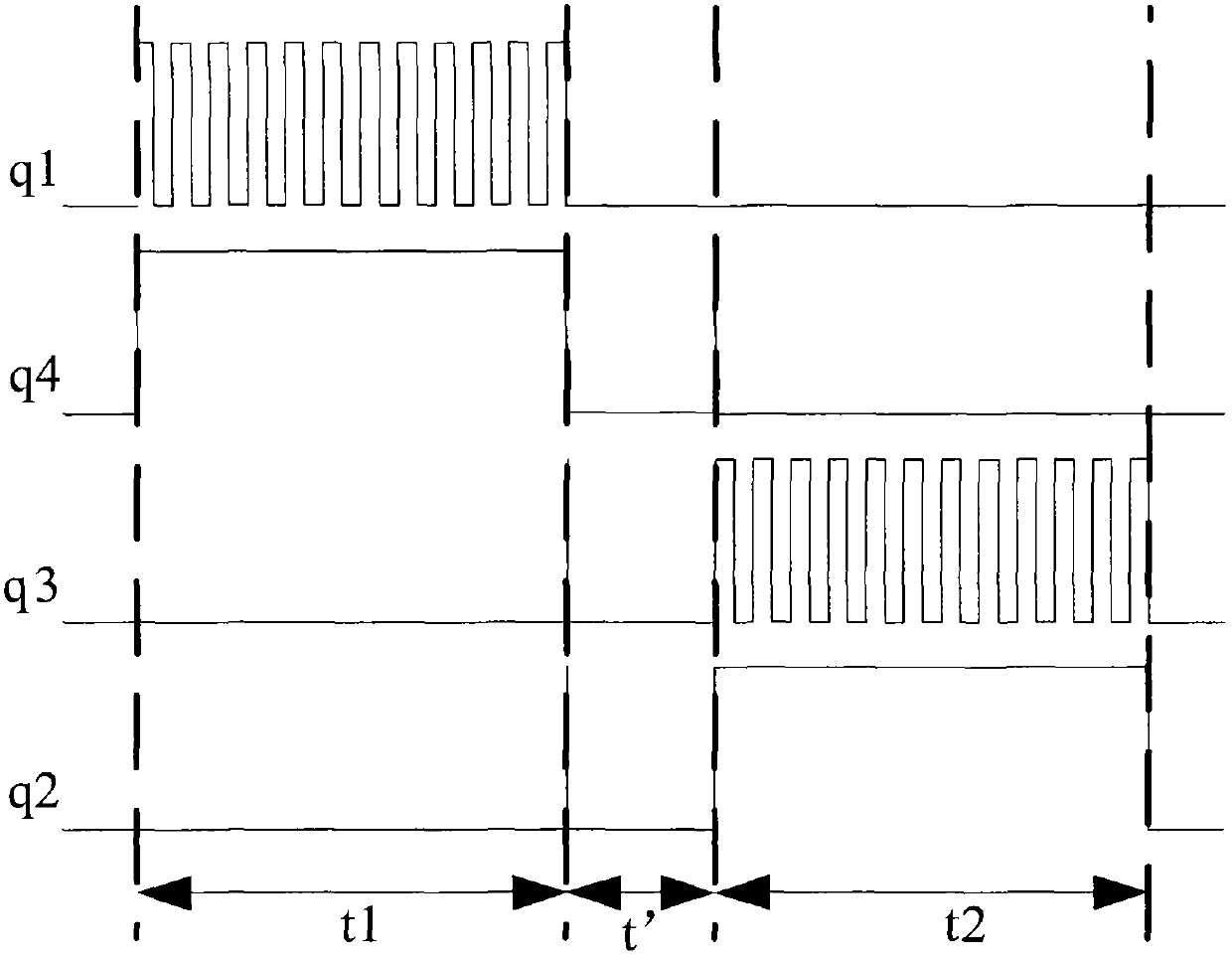

[0013] Such as figure 2 As shown, it is defined that the H-bridge drive circuit works in the positive direction during the t1 period, and the H-bridge drive circuit works in the negative direction during the t2 period, then the t2 period is called the H-bridge drive circuit commutation relative to the t1 period, and the t' period is H During the transition period during the commutation process of the bridge drive circuit, the transistor Q1, the transistor Q2, the transistor Q3 and the transistor Q4 are all in the off state during the t' period. That is to say, the large-energy independent discharge circuit is only used in the t' period, and the large-energy independent discharge circuit does not work in other periods.

[0014] The inductance of the large magnetic moment magnetic torque device is very large, and the stored energy is also large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com