Stainless steel corrugated hose connecting devicefor fuel gas transportation

A corrugated hose, connecting device technology, applied in the direction of hose connecting device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problem of reducing the safety and service life of corrugated hose, limiting the scope of use, reducing the sealing performance, etc. problems, to achieve the effect of easy installation, improved axial tensile strength, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

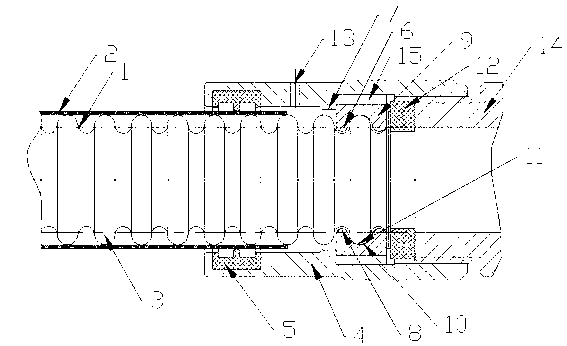

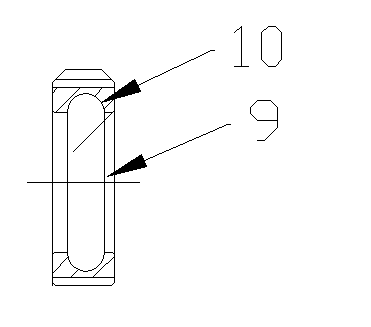

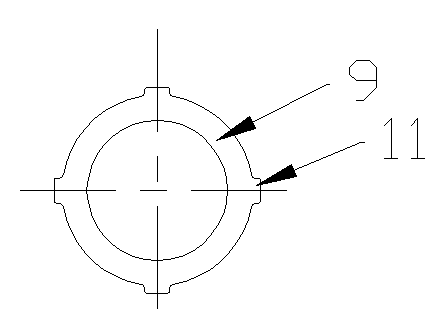

[0015] Such as figure 1 , 2 , 3, the present invention is a stainless steel corrugated hose connection device for gas transmission, comprising a corrugated hose 1 and a plastic sheath 2 covering it, the inner wall of the plastic sheath 2 is evenly distributed with a number of gas guides groove 3, the outer sheath of the plastic sheath is provided with a through seat 4, a sealing ring 5 is provided between one end of the through seat and the plastic sheath, the inner circle of the other end of the through seat is provided with a thread 6, and the bottom of the thread is provided with There is an undercut 7, four grooves 8 are provided on the thread, and a clamping ring 9 is provided on one side of the undercut, wherein the clamping ring is a metal ring separated in two halves, and the inner circle of the clamping ring There is a groove 10, the groove matches the corrugated shape of the corrugated hose, and the outer circle of the clamping ring is provided with 4 bosses 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com