Stepless speed change device with transmission diameter variable wheel hub

A continuously variable transmission, variable diameter wheel technology, applied in transmission, transmission control, belt/chain/gear, etc., can solve problems such as torque and power limitation, and meet the requirements of improving transmission torque and power, manufacturing and installation accuracy The effect of lowering and increasing the allowable value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

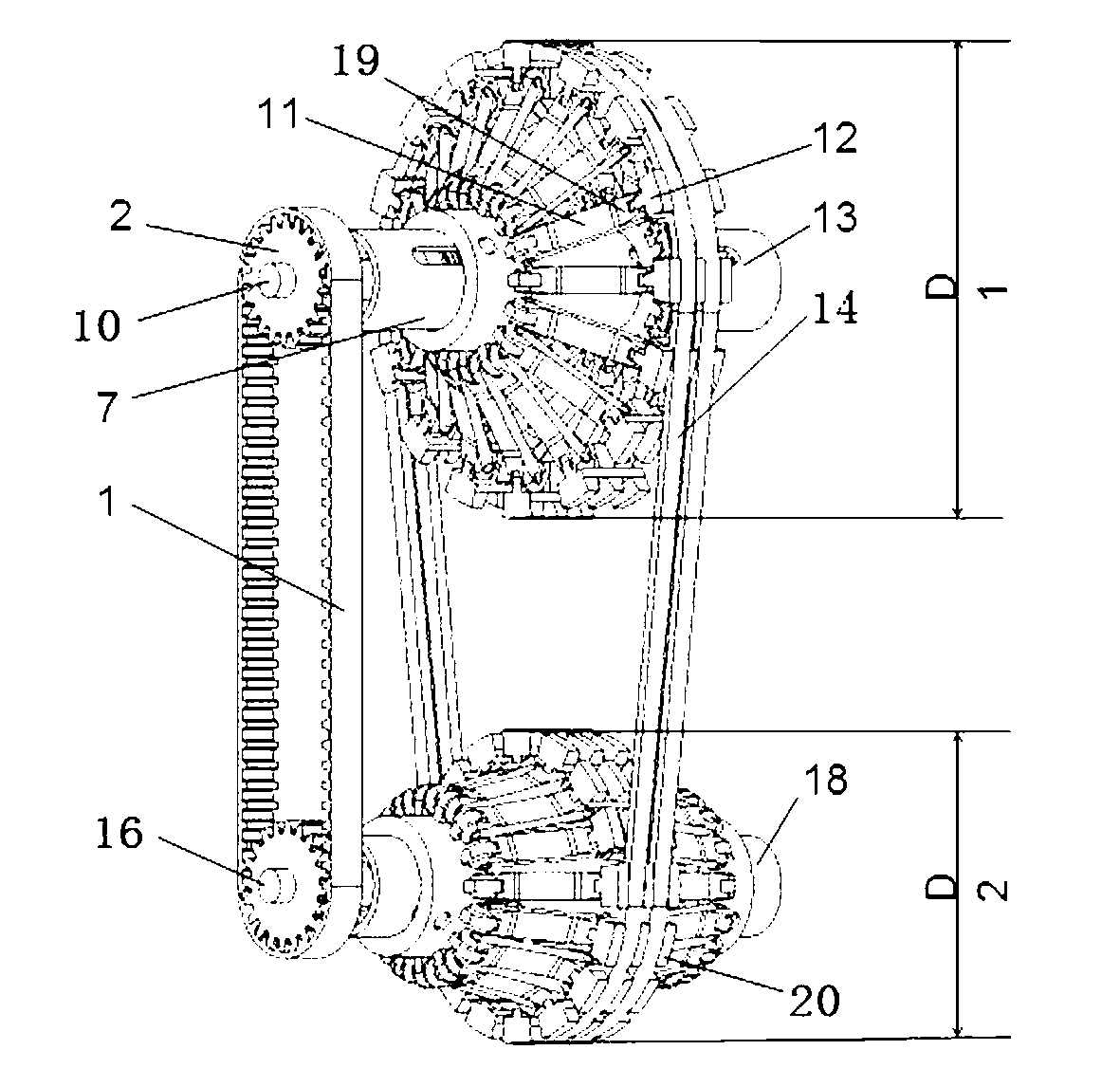

[0026] Embodiment: The purpose of this embodiment is to change the diameter of the active variable diameter hub 19 and the passive variable diameter hub 20 with the same structure, and realize the stepless speed change from the input shaft 13 to the output shaft 18 by the frictional traction force of the V-belt 14 .

[0027] Such as figure 1 , 2 , Shown in 4, the variable diameter process of active variable diameter hub 19 is realized by following structure: assembly synchronous belt pulley 2 is assembled on the left end shaft shoulder of active variable pitch screw mandrel 10, and synchronous belt 1 is assembled on synchronous belt pulley 2. The input shaft 13 is coaxially assembled with the active pitch variable screw rod 10 , and the sliding sleeve 7 is sleeved on the input shaft 13 and can slide along the axial direction of the input shaft and 13 . Sixteen inner hinges are evenly distributed on the sliding sleeve 7, and the inner hinges on the sliding sleeve 7 and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com