Air power drive device

A driving device and aerodynamic technology, applied in the direction of machines/engines, non-variable engines, mechanical equipment, etc., can solve the problems of unusable motors, high energy consumption, environmental pollution, etc., and achieve energy sanitation, energy saving, environmental protection, and portable transportation Convenience and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

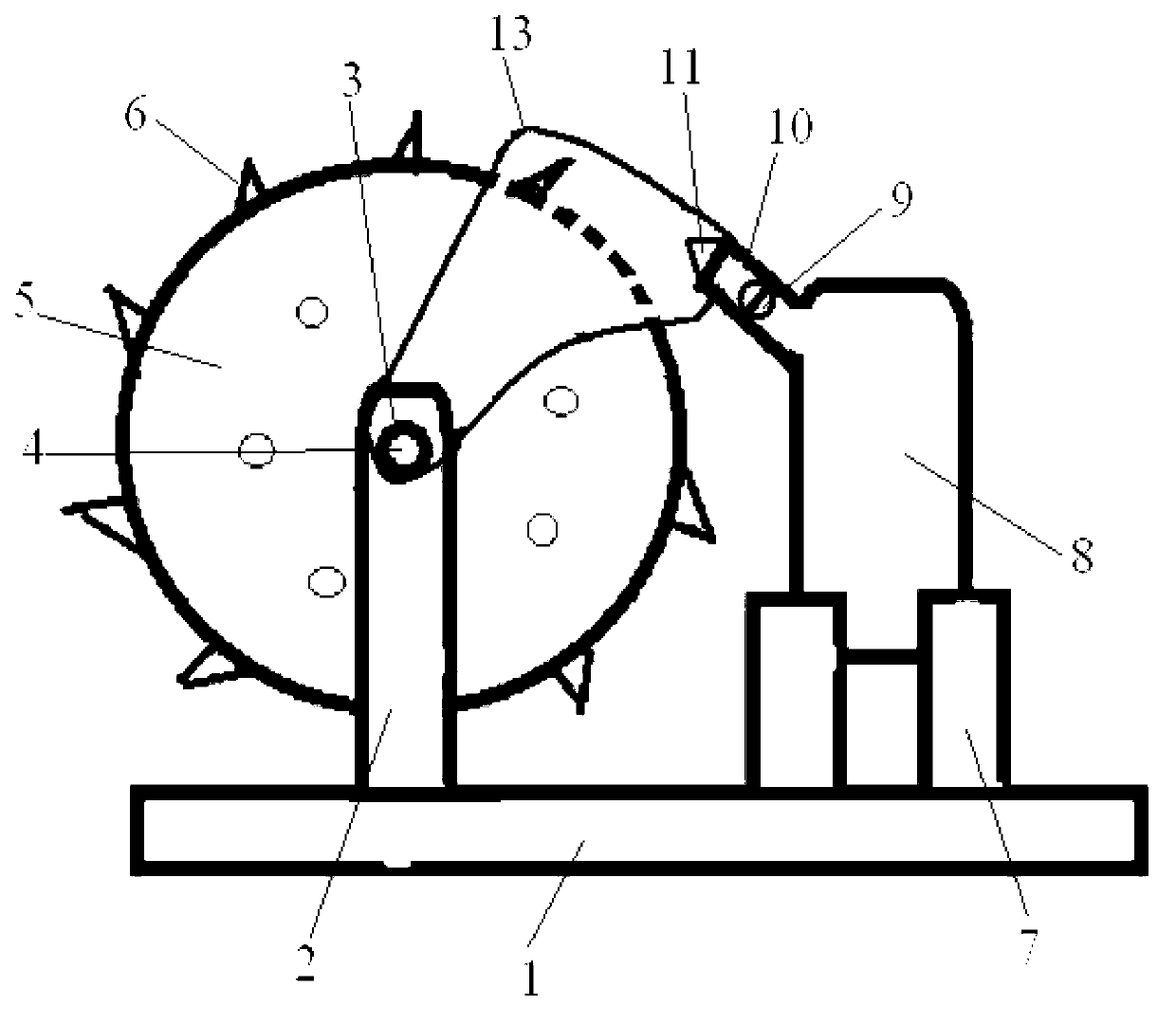

[0017] Such as figure 1 As shown, the present invention utilizes the principle of leverage to inject air into the wheel rim of a runner, push the runner to rotate with the rotating shaft through air force, and use the rotating shaft as the output shaft to output power outward.

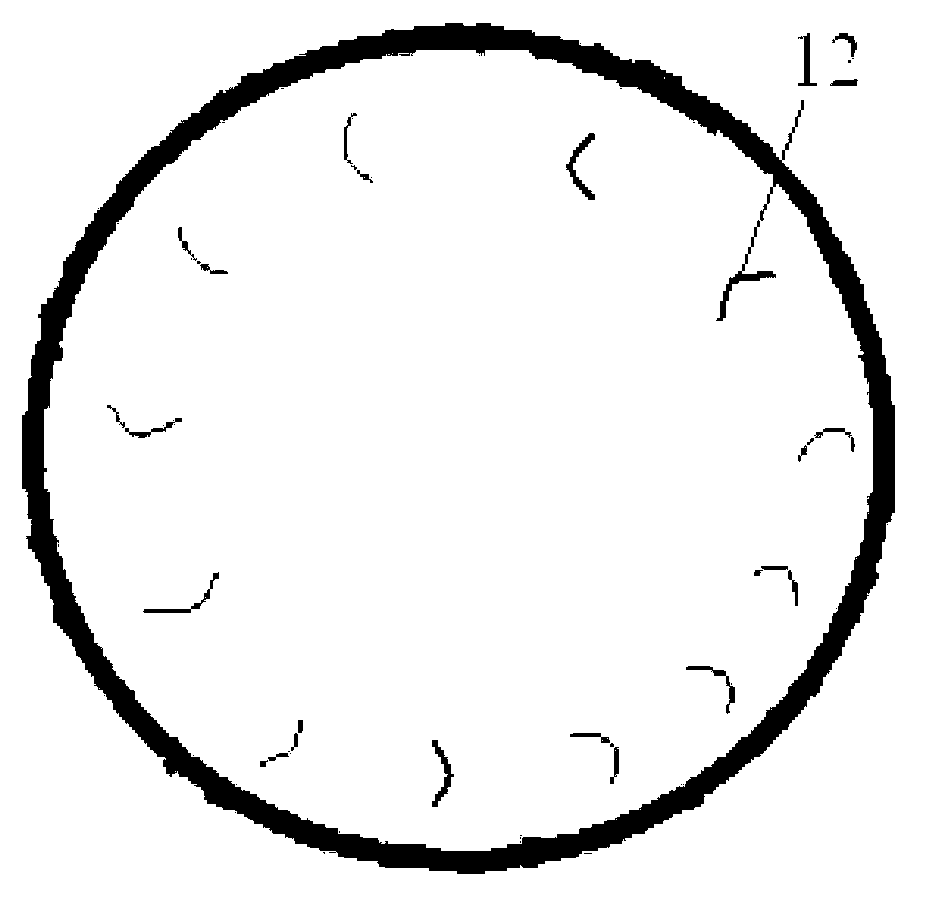

[0018] The present invention comprises a base 1, one side of the base 1 is provided with a pair of upright columns 2 as a supporting frame, two bearings 3 are arranged symmetrically on the top of the two upright columns 2, and the two bearings 3 jointly support a rotating shaft 4, and the rotating shaft 4 is fixedly connected with a set Runner 5 between two uprights 2. One end of the rotating shaft 2 protrudes to connect the input shaft of the generator. A plurality of protruding blades 6 as force-bearing elements are provided at intervals on the circumferential edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com