A kind of silicon steel pickling stabilization material and using method thereof

A technology for stabilizing materials and silicon steel acid, which is applied in the field of pickling, can solve the problems of increasing broken belts and edge cracking accidents, affecting unit production capacity, and increasing production costs, so as to avoid excessive pickling, reduce pickling energy consumption, and increase production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

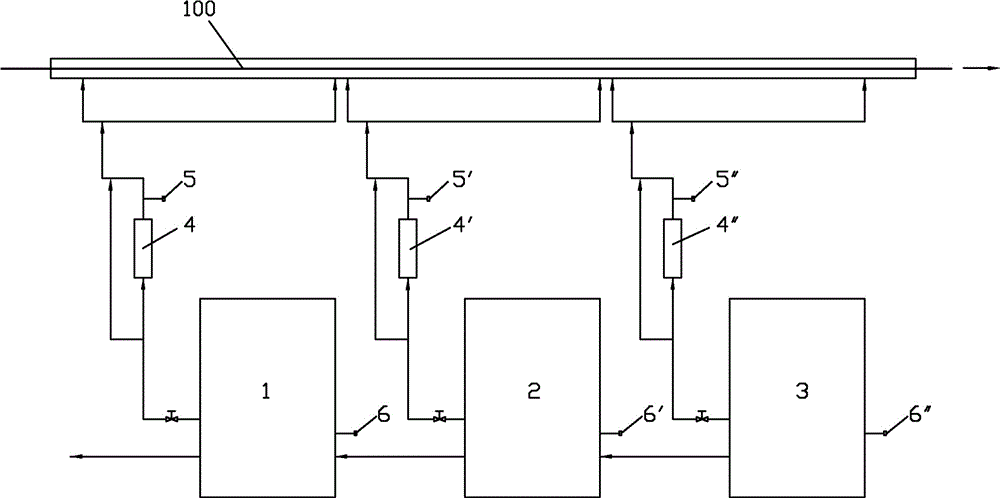

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Pickling of non-chemical silicon steel

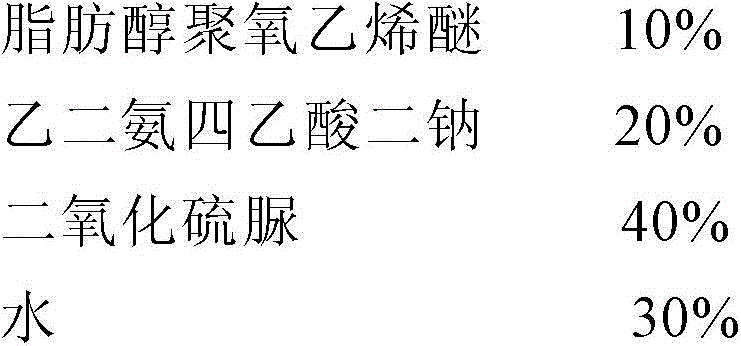

[0037] Pickling Accelerator:

[0038]

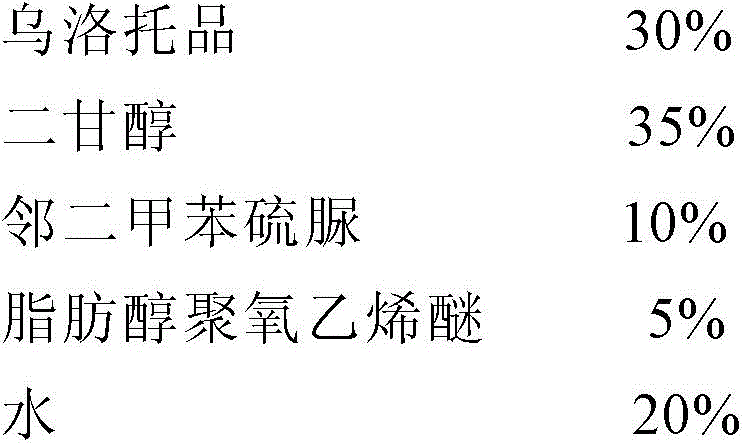

[0039] Inhibitors:

[0040]

[0041] Add the pickling accelerator into the second pickling tank according to the proportion of 2.0% of the acid liquid circulation volume, keep the concentration of hydrochloric acid in the first pickling tank between 3% and 5%, and the temperature is 85°C. The concentration of hydrochloric acid in the tank is between 4% and 6%, the temperature is 83°C, and the inhibitor is added to the third pickling tank according to the proportion of 0.5% of the acid liquid circulation, and the concentration of hydrochloric acid in the third pickling tank is kept at 8-6%. Between 10%, the temperature is at 80°C.

[0042] Adopt above-mentioned embodiment silicon steel pickling stabilizing material and pickling process parameter, can make the unit pickling speed of turbulent flow pickling unit reach 200 m / min when pickling exempt from normalization sili...

Embodiment 2

[0043] Embodiment 2: Pickling of non-chemical silicon steel

[0044] Pickling Accelerator:

[0045]

[0046] Inhibitors:

[0047]

[0048] Add the pickling accelerator to the second pickling tank according to the proportion of 2.0% of the acid liquid circulation volume, keep the concentration of hydrochloric acid in the first pickling tank between 3.5 and 6.5%, and the temperature is 80°C. The concentration of hydrochloric acid in the tank is between 7% and 12%, the temperature is 83°C, and the inhibitor is added to the third pickling tank according to the proportion of 1.5% of the acid liquid circulation, and the concentration of hydrochloric acid in the third pickling tank is kept at 8-10%. Between 14%, the temperature is at 80°C.

[0049] Adopt above-mentioned embodiment silicon steel pickling stabilizing material and pickling process parameter, can make the unit pickling speed of turbulent flow pickling unit reach 200 m / min when pickling exempt from normalization s...

Embodiment 3

[0050] Embodiment 3: pickling of normalized silicon steel

[0051] pickling accelerator

[0052]

[0053] Inhibitors:

[0054]

[0055] The pickling stabilizer prepared according to the above formula is added to the second pickling tank according to the proportion of 0.5% of the acid liquid circulation, and the concentration of hydrochloric acid in the first pickling tank is kept at 3-5%. between, the temperature is 85°C, the concentration of hydrochloric acid in the second pickling tank is between 4% and 6%, the temperature is 80°C, and the inhibitor is added to the third pickling tank according to the proportion of 0.5% of the acid liquid circulation, keeping The concentration of hydrochloric acid in the third pickling tank is between 8% and 10%, and the temperature is at 75°C.

[0056] Adopt above-mentioned embodiment silicon steel pickling stabilizing material and pickling process parameter, can make the unit pickling speed of turbulent flow pickling unit reach 230...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com