Combined process for hydrotreatment of heavy oil

A technology of hydrotreating and combined process, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problem of high investment, achieve the effect of prolonging operation time, maintaining long-term stable operation, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation process of the ebullated bed hydrotreating catalyst is to firstly prepare the microspherical catalyst carrier, and then use the impregnation method to support the required hydrogenation active metal components. The preparation process of the catalyst carrier is as follows: the raw materials of the catalyst carrier with suitable humidity are made into particles of suitable size, and then the particles are spheroidized, and the spheres are dried and calcined to form a spherical catalyst carrier.

[0041] The drying and calcination of the catalyst carrier can adopt conditions well known to those skilled in the art, such as natural drying or drying at 80-150°C, and calcination at 600-1000°C for 1-6 hours. The impregnation method to support the active hydrogenation metal component can be carried out by methods well known to those skilled in the art, such as making a solution of the required active metal salt, impregnating the catalyst carrier with the solution...

Embodiment 1

[0045] Catalyst preparation

[0046] A spherical catalyst carrier is prepared, the average pore diameter is 24nm, and the spherical particle diameter is 0.1-0.3mm. Prepare the Mo-Ni solution according to the conventional method, and use MoO in the solution 3 The content by weight is 8.00%, and the content by weight of NiO is 1.80%. The above-mentioned support was impregnated with the solution in an equal-volume impregnation method to obtain the final catalyst R101-C, the properties of which are shown in Table 1.

[0047] A spherical catalyst carrier with an average pore diameter of 15 nm is prepared, and the spherical catalyst particle size is 0.1-0.3 mm. Prepare the Mo-Ni-P solution according to the conventional method, and use MoO in the solution 3 The content by weight is 13.00%, the content by weight of NiO is 2.50%, and the content by weight of P is 1.00%. The above-mentioned support was impregnated with this solution by an equal-volume impregnation method to obtain t...

Embodiment 2

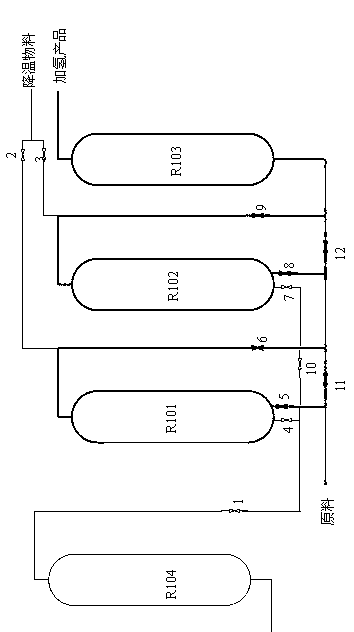

[0054] The ebullating bed hydrogenation reactor described in the present invention is a three-phase ebullating bed reactor, and the ebullating bed reactors disclosed in CN02109404.7, CN200610134154.5 and CN200710012680.9 can be used, which can satisfy gas, liquid, solid The three phases are separated in the ebullated bed reactor.

[0055] Select R101-C, R102-C and R103-C catalysts in Example 1 to join respectively in three series-connected 1L three-phase ebullating bed reactors, FZC-40 catalysts are packed into a fixed bed reactor R-1, In the presence of hydrogen, a vacuum residue hydrotreating test was carried out. The properties of the vacuum residue selected for the test are: distillation range 520°C +, the sulfur content is 2.60% by mass, the metal (Ni+V+Fe) content is 253 μg / g, the CCR (carbon residue) content is 12.1% by mass, and the asphaltene content is 5.9% by mass.

[0056] The test conditions and evaluation results are shown in Table 2.

[0057] Table 2 Process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com