Method for producing n-vinyl pyrrolidone

A technology of vinylpyrrolidone and pyrrolidone, which is applied in the fields of fine chemical industry and chemical pharmacy, can solve the problems of high production process cost, high cost, large dosage, etc., and achieve the effect of shortening reaction time, low price and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

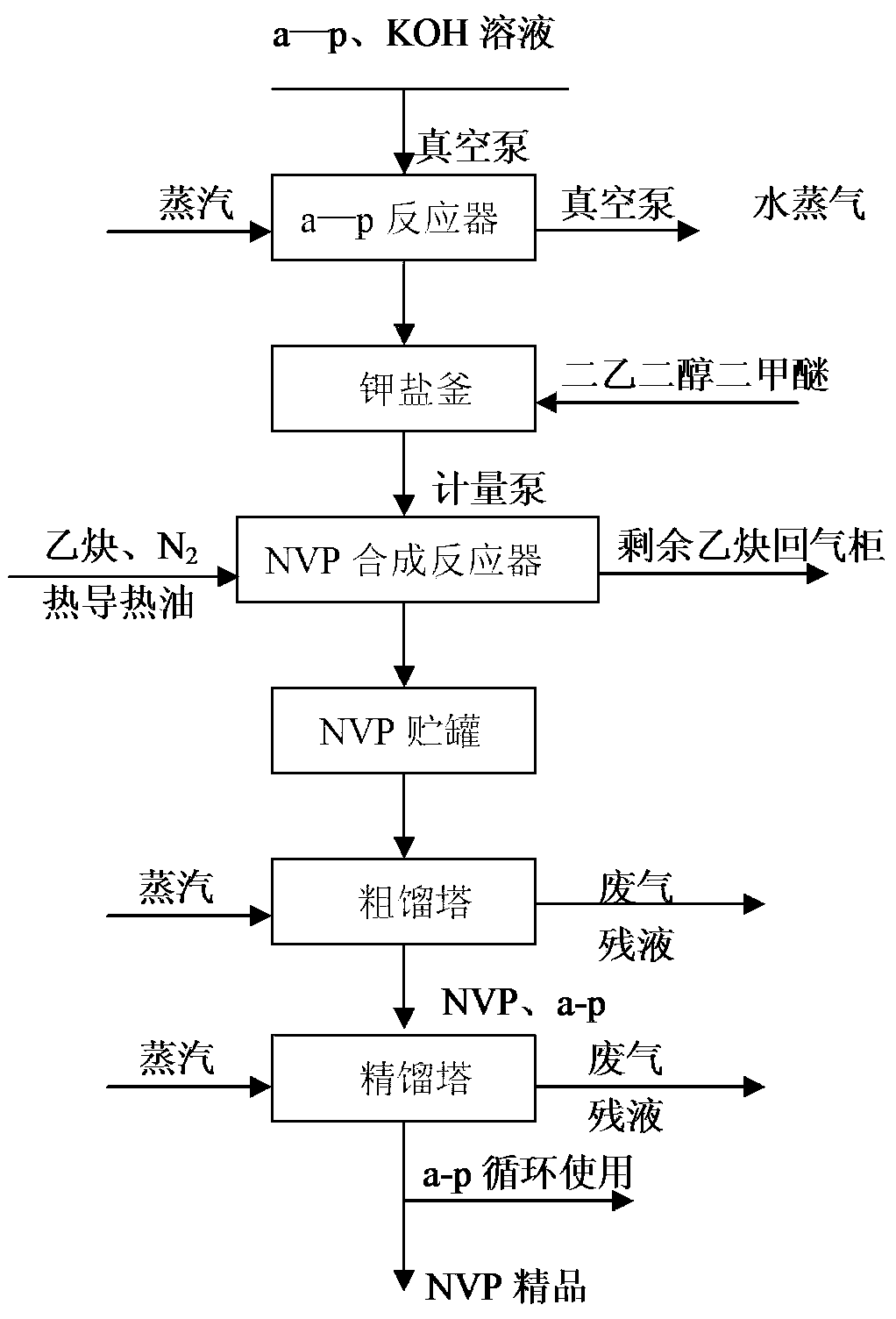

Method used

Image

Examples

Embodiment 1

[0018] a. Add 104ga-pyrrolidone and 2g potassium hydroxide into the potassium salt reactor and heat under reduced pressure, keep 110°C for full reaction, stop heating when the water content of the distilled liquid is less than 0.05%,

[0019] B, add 1.06g diethylene glycol dimethyl ether in the potassium salt storage tank, put into the storage tank after stirring and mixing;

[0020] c. Pass the mixed gas of acetylene and nitrogen with a volume ratio of 8:2 into the high-pressure reactor, and at the same time pump the mixed solution of a-p potassium salt, a-p and diglyme ether prepared above into the high-pressure reactor to control The temperature is 130°C-150°C, the pressure is controlled at 12 atmospheres, and the reaction is carried out for 3 hours. The reacted mixed liquid is distilled to separate the unreacted a-p and NVP, and the distilled NVP is collected and then rectified to obtain the target product vinylpyrrolidone. (NVP).

[0021] The conversion rate was detected...

example 2

[0023] a. Add 260ga-pyrrolidone and 5g potassium hydroxide into the potassium salt reactor and heat under reduced pressure, keep 110°C for full reaction, and stop heating when the moisture in the distilled liquid is less than 0.05%;

[0024] b. Add 2.65g of diethylene glycol dimethyl ether, stir and mix evenly, and then put it into the storage tank;

[0025] c. The mixed gas of acetylene and nitrogen with a volume ratio of 8:2 is passed into the high-pressure reactor, and at the same time, the mixture of a-p potassium salt, a-p and diethylene glycol dimethyl ether prepared above is pumped into the high-pressure reactor to control the temperature React at 130°C to 150°C with pressure controlled at 12 atmospheres for 3 hours, distill the reacted mixed liquid to separate unreacted a-p and NVP, collect the distilled NVP and rectify to obtain the target product vinylpyrrolidone ( NVP).

[0026] The conversion rate was detected to be 88.9%, and the yield of the target product NVP w...

example 3

[0028] a. Add 1040ga-pyrrolidone and 20g potassium hydroxide into the potassium salt reactor and heat under reduced pressure, keep 110°C for full reaction, and stop heating when the moisture in the distilled liquid is less than 0.05%;

[0029] b. Add 10.6g of diethylene glycol dimethyl ether, stir and mix evenly and put it into the storage tank;

[0030] c. Pass the mixed gas of acetylene and nitrogen with a volume ratio of 8:2 into the high-pressure reactor, and at the same time pump the mixed solution of a-p potassium salt, a-p and diglyme ether prepared above into the high-pressure reactor to control The temperature is 130°C-150°C, the pressure is controlled at 12 atmospheres, and the reaction is carried out for 3 hours. The reacted mixed liquid is distilled to separate the unreacted a-p and NVP, and the distilled NVP is collected and then rectified to obtain the target product vinylpyrrolidone. (NVP).

[0031] The conversion rate was detected to be 88.7%, and the yield of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com