Motive power mixing device of hybrid car

A hybrid electric vehicle and power hybrid technology, which is applied to hybrid electric vehicles, power units, air pressure power units, etc., can solve the problems of battery pack charging, increased kinetic energy consumption, and uncoordinated speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

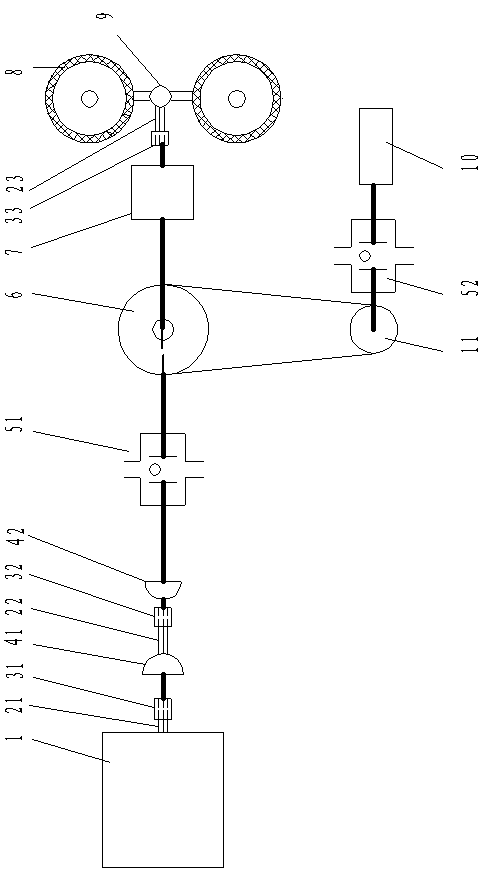

[0016] Combine below figure 1 , describe in detail the concrete working situation that the present invention proposes.

[0017] On the internal-combustion engine power output shaft 21, after the internal-combustion engine and its attached transmission 1, before the differential 9, select an appropriate position, that is, at the original design power interruption place, or at the artificial cut-off place now, the internal-combustion engine (fuel engine) )1 The output shaft is connected with the inner ring (or outer ring) of the overrunning clutch 51 (key fit is available). At this time, the inner ring (or outer ring) of the overrunning clutch 51 rotates in the forward direction to rotate with load and is connected with the internal combustion engine 1 The forward rotation is consistent; the outer ring (or inner ring) of the overrunning clutch 51 cooperates with the part after the disconnection of the output shaft, usually by adding an outer (inner) cover and fixing with a key. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com