Clamping jaw mechanism

A clamping jaw and frame technology, which is applied in the field of automated machinery and equipment manufacturing, can solve the problems of the hinged clamping jaw mechanism not clamping tightly, the force of the hinged shaft is large, and the service life is affected, so as to prolong the service life and increase the clamping force. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

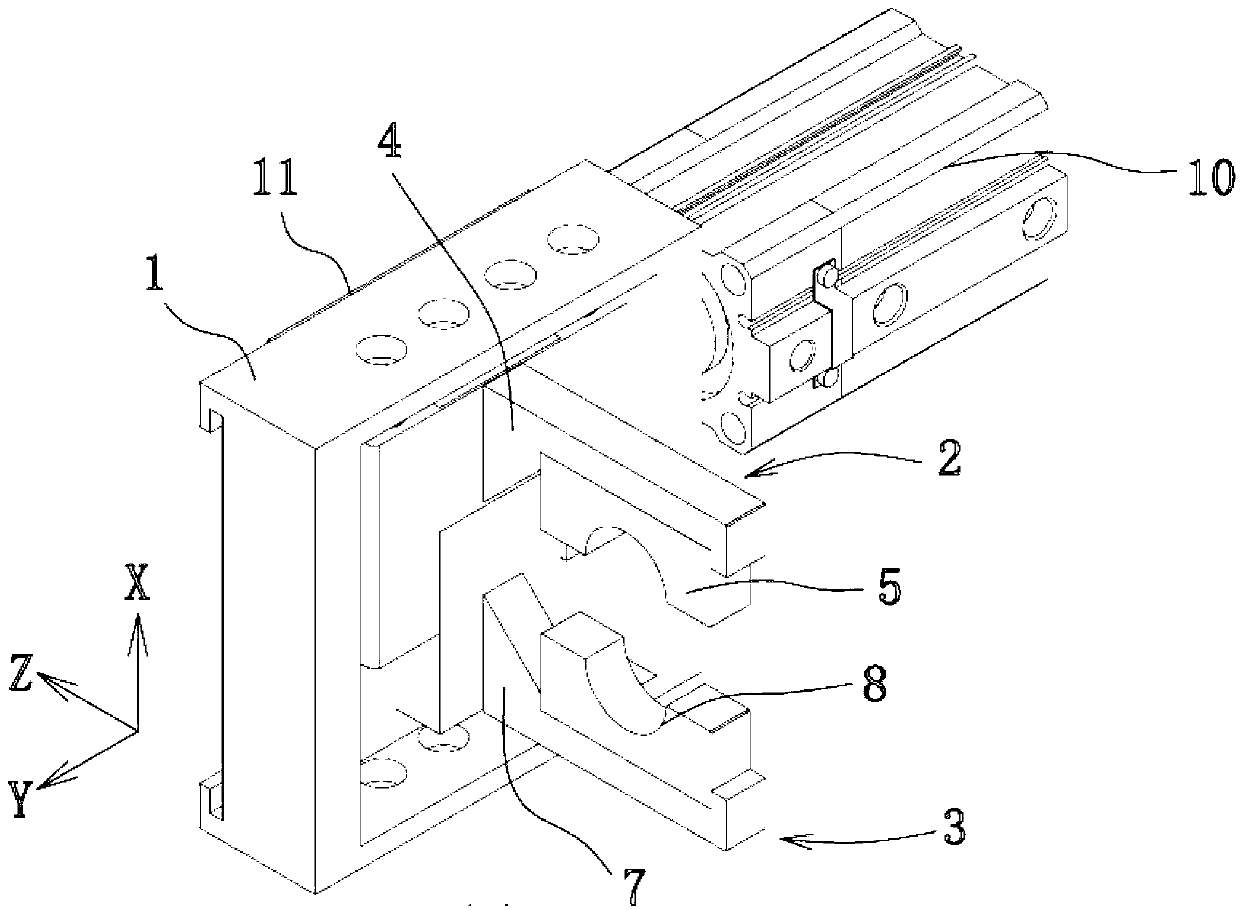

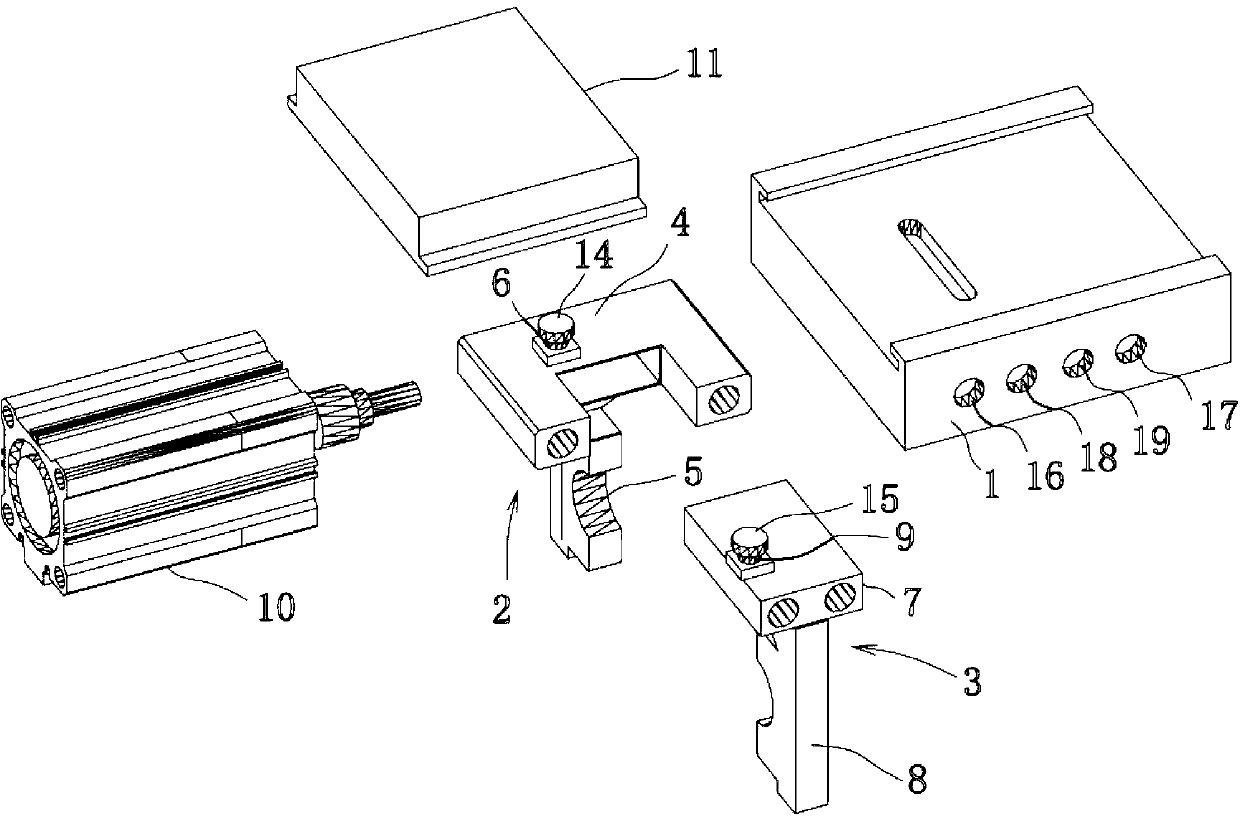

[0025] Example: see attached Figures 1 to 4 As shown, a clamping claw mechanism includes a frame 1, a left claw portion 2 and a right claw portion 3. The left claw portion 2 has a left claw seat 4 on which a left claw 5 is fixed. The claw base 4 is slidably connected with the frame 1 along the X axis, and the left claw base 4 is provided with a left claw slider 6;

[0026] The right claw portion 3 has a right claw seat 7 on which a right claw 8 is fixed, the right claw seat 7 is slidably connected with the frame 1 along the X axis, and a right claw slider is arranged on the right claw seat 7 9;

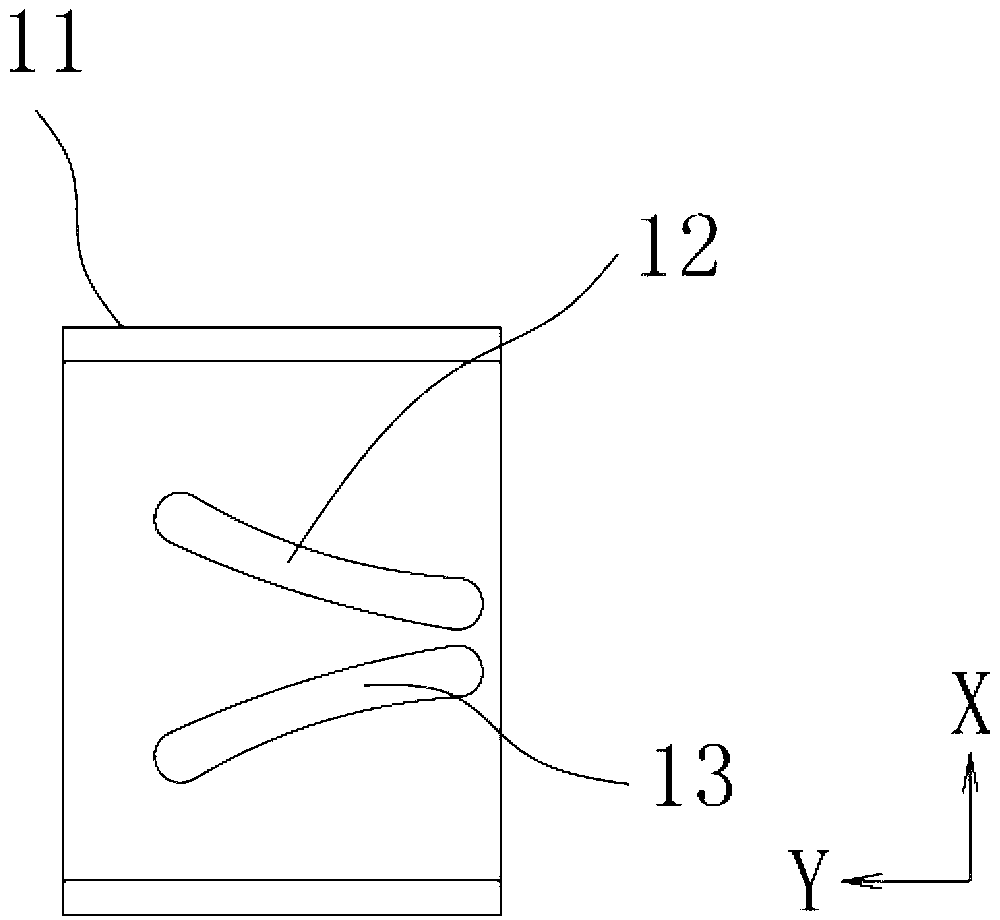

[0027] It also includes a linear drive device 10 and a push slider 11, the push slider 11 is slidably connected with the frame 1 along the Y axis; the push slider 11 is provided with a left slide rail 12 and a right slide rail 13, the The X-axis distance between the left slide rail 12 and the right slide rail 13 gradually increases along the Y-axis direction. The left claw slider 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com