Penoxsulam-amidosulfuron weeding composition

A technology of penoxsulam and herbicidal composition, applied in the directions of herbicides, algaecides, biocides, animal repellents, etc., to achieve the effects of convenient use, reducing adverse effects and reducing the frequency of medication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 (8% penoxsulam · rimsulfuron oil suspension):

[0027] Penoxsulam 2%,

[0028] Acylsulfuron-methyl 6%,

[0029] Styrene phenol ethoxylate 5%,

[0030] Sodium Lignosulfonate 8%,

[0031] Epoxidized soybean oil 5%,

[0032] Organic bentonite 5%,

[0033] Refined soybean oil to 100%.

[0034] Put the above materials (except organic bentonite) into the reaction kettle mixer together, stir for 2 hours, open the feed valve at the bottom of the kettle, inject the materials into the multi-stage sand mill for grinding, and the fineness of the ground materials is 98% through 1- After 5um, the material is discharged, and the material is put into a high-shear emulsification kettle together with the pre-dissolved organic bentonite. After emulsification, it can be made into 8% penoxsulam · rimsulfuron oil suspension concentrate with good flowability .

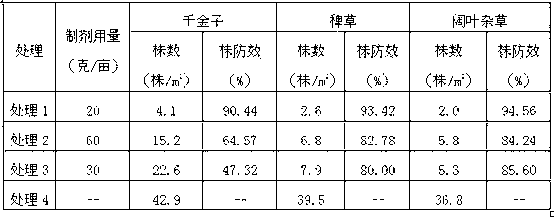

[0035] This example is used to prevent and control annual weeds in direct-seeded rice fields: the test is carried ...

Embodiment 2

[0039] Example 2 (20% penoxsulam · rimsulfuron water dispersible granules):

[0040] Penoxsulam 5%,

[0041] sulfuron-methyl 15%,

[0042] Sodium Lauryl Sulfate 4%,

[0043] Carboxylate 5%,

[0044] Urea 40%,

[0045] Kaolin up to 100%.

[0046] Put the above materials together into the conical mixer and mix evenly, and then pulverize through the jet mill, and then mix the pulverized materials through the conical mixer. Knead into a plastic material, and finally put the material into an extrusion granulator to extrude and granulate. After granulation, dry and sieve to obtain 20% penoxsulam·sulfuron-methyl water-dispersible granules.

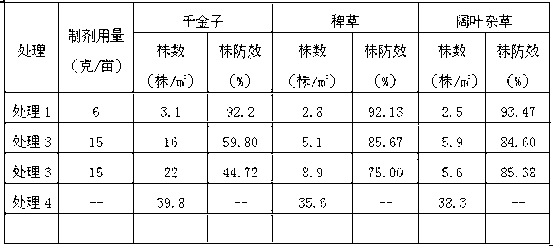

[0047]This example is used to prevent and control annual weeds in rice seedling throwing fields: the experiment is carried out in rice seedling throwing fields with many weeds, barnyardgrass and broad-leaved weeds. There are 4 treatments in the experiment, and treatment 1 is 20% penoxsulam · Sulfur-methyl water-dispersible granules, treat...

Embodiment 3

[0051] Example 3 (15% penoxsulam · rimsulfuron wettable powder):

[0052] Penoxsulam 5%,

[0053] sulfuron-methyl 10%,

[0054] Sodium Lauryl Sulfate 2%,

[0055] Sodium butylnaphthalene sulfonate 3%,

[0056] Calcium Lignosulfonate 5%,

[0057] Silica 5%,

[0058] Kaolin up to 100%.

[0059] Put the above materials together into the conical mixer and mix them evenly, and then pulverize them through the jet mill, and then mix the pulverized materials through the conical mixer. Penoxsulam · rimsulfuron wettable powder.

[0060] This example is used to prevent and control annual weeds in rice seedling throwing fields: the experiment was carried out in a rice transplanting field with many weeds such as Qianjinzi, barnyardgrass and broad-leaved weeds. There were 4 treatments in the experiment, and treatment 1 was 15% penoxsulfonate For rimsulfuron-methyl wettable powder, treatment 2 was a single dose of 10% penoxsulam wettable powder, treatment 3 was a single dose of 20% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com