Waste heat utilization thermoelectric power generation pipeline device

A power generation device and thermoelectric power generation module technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of low technical level of low-temperature waste heat recovery, increase of cost capital, slow progress, etc., and achieve excellent heat flux variable performance and environmental protection The effect of improved adaptability and easy modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

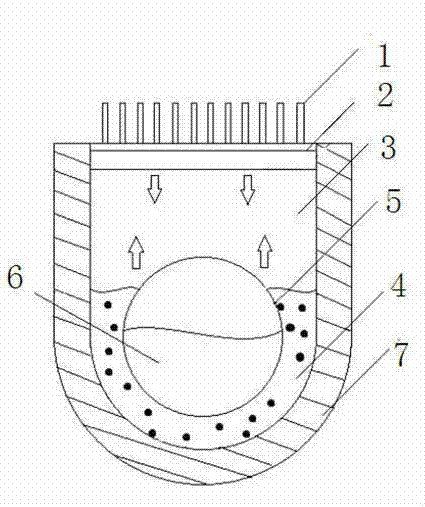

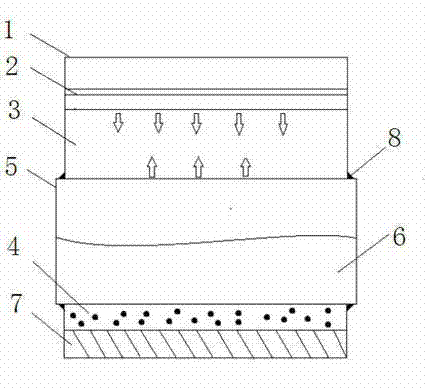

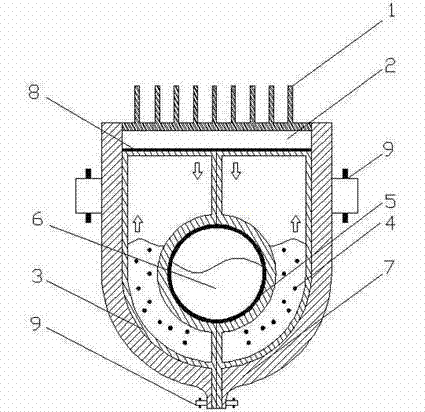

[0014] figure 1 , figure 2 It is a schematic diagram of the structure of the waste heat thermoelectric power generation tube, as shown in the figure: the medium and low temperature thermal fluid 6 with waste heat flows in the heat flow pipe 5, and the heat flow pipe 5 is covered by the working medium 4 of the heat transfer device. The U-shaped part of the heat transfer device 3 has good thermal insulation performance to reduce the heat loss during the phase change transfer process of the working fluid 4 of the heat transfer device. The horizontal part of the heat transfer device 3 closely connected to the hot end of the thermoelectric power generation module 2 has good thermal conductivity to ensure High efficiency utilization of working fluid heat. The cold end of the thermoelectric power generation module 2 is in close contact with the heat sink fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com