Laser module temperature control testing device

A test device and laser module technology, applied in the field of laser applications, can solve problems affecting test accuracy, temperature change speed and temperature control range, vibration and static electricity, etc., to achieve the effect of improving test efficiency, good test environment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

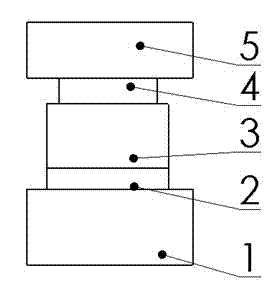

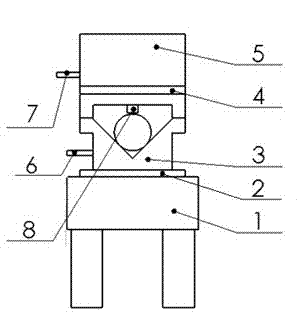

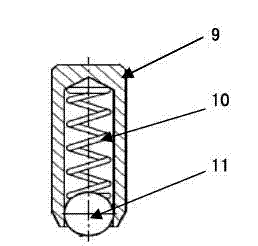

[0028] The laser module temperature control test device of the present invention comprises a fixed platform 1, and a clamping device 3, a cooling plate 4, and a radiator 5 are arranged from bottom to top above the fixed platform 1, and it also includes a temperature control device, which includes a single-chip microcomputer, a temperature control device, and a temperature control device. Sensors and temperature sensors are connected to the single-chip microcomputer, and are centrally controlled by the single-chip microcomputer. The temperature sensor is fixed on the radiator and the clamping device, and the first temperature sensor 6 is connected to the clamping device, and the second temperature sensor 7 is connected to the radiator. , the single chip microcomputer automatically adjusts the PID parameter value according to the feedback temperature difference of the temperature sensor. A thermal insulation board 2 is arranged between the clamping device 3 and the fixed platform...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the heat insulation plate of this embodiment is made of alumina, and the material of the clamping device and the heat sink is made of steel.

Embodiment 3

[0033] The difference between this embodiment and Embodiment 1 is that the heat insulating plate of this embodiment is set as ceramics, and the material of the clamping device and the heat sink is set as copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com