Multiple anti-fake carbon powder and its preparation method

A multiple, toner technology, applied in electrical recording, optics, instruments, etc., can solve the problems of low technical content of anti-counterfeiting toner, low anti-counterfeiting strength, easy imitation, etc. difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025]

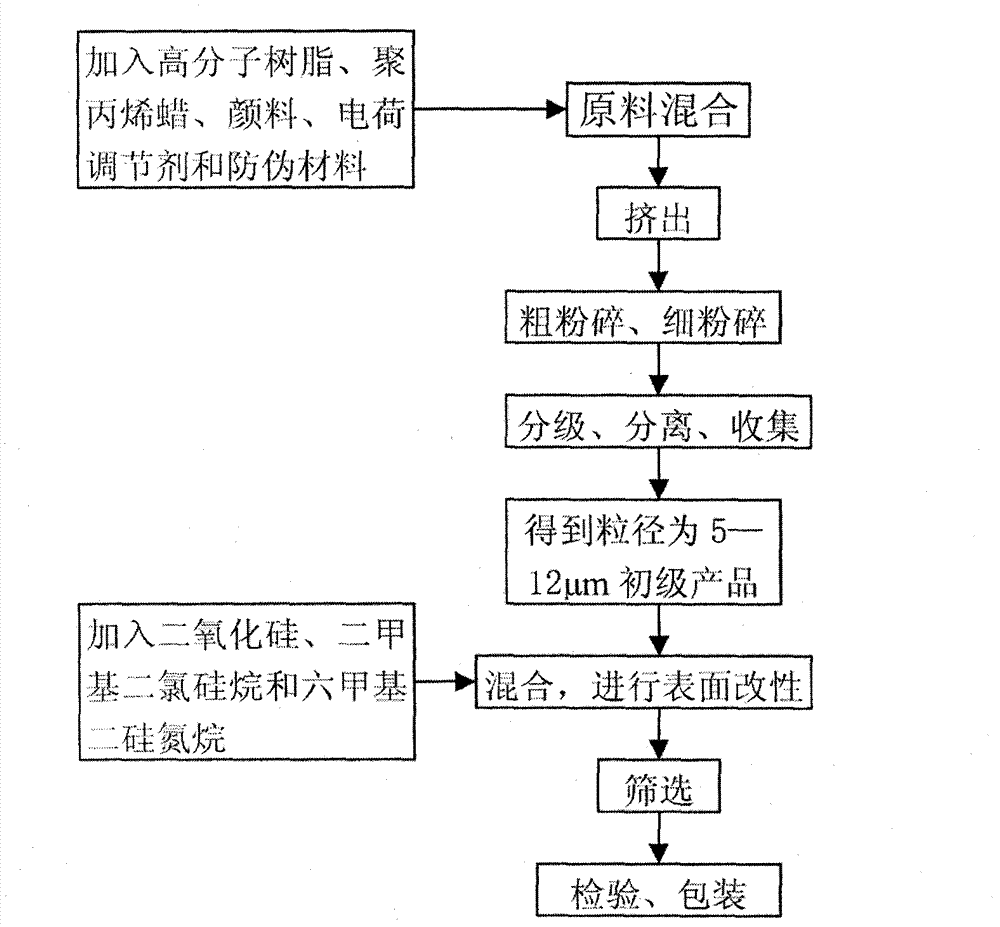

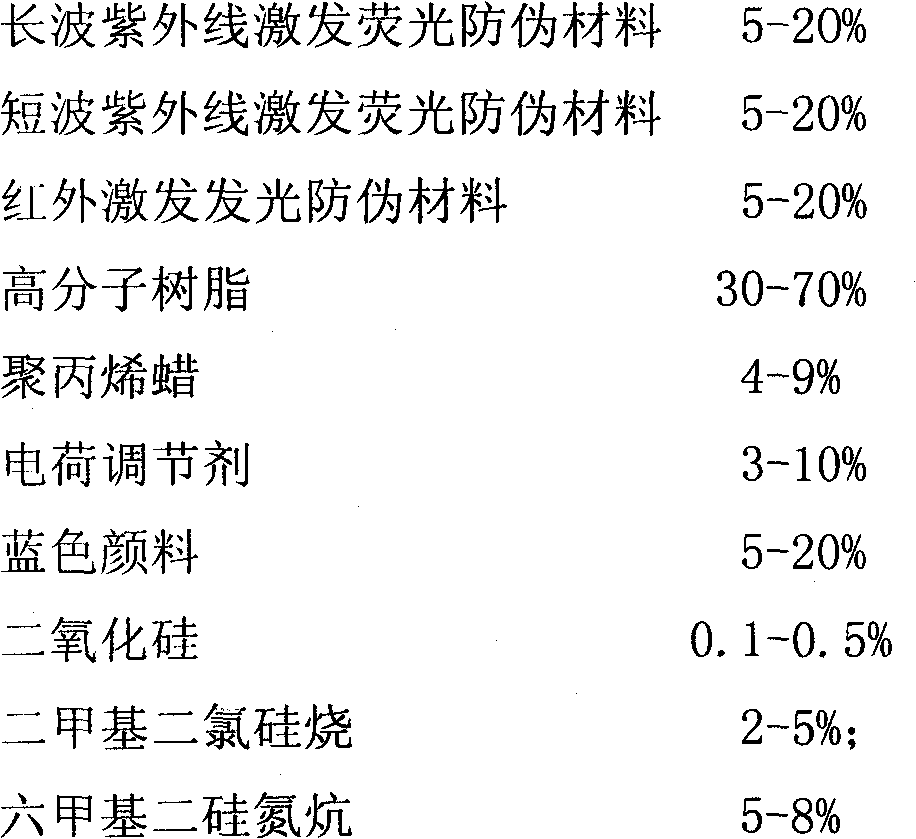

[0026] 10 kg of anti-counterfeiting toner is produced in each batch, according to the proportion of the above formula components, and made according to the following steps:

[0027] (1) Evenly mix polymer resin, polypropylene wax, blue pigment, charge regulator and anti-counterfeiting material in a mixer to make a mixture;

[0028] (2) Then put the above mixture into the extruder, and slowly heat it, press the above mixture into tablets at a temperature of 100-155°C, and grind it into powder with a coarse powder machine after cooling:

[0029] (3) After that, use a fine powder machine to further pulverize the above-mentioned pulverized powder, and carry out classification, separation, and collection to obtain a primary product with a particle size of 5--12 μm:

[0030] (4) Add silicon dioxide, dimethyldichlorosilane and hexamethyldisilazane, and mix with a mixer to modify the surface so that the fluidity is greater than 20%.

[0031] (5) Screen with 150--250 mesh ...

example 2

[0034]

[0035]

[0036] 10 kg of anti-counterfeiting ink is produced in each batch, and the proportion of the above formula components is controlled, and the production is made according to the following steps:

[0037] (1) Evenly mix polymer resin, polypropylene wax, blue pigment, charge regulator and anti-counterfeiting material in a mixer to make a mixture;

[0038] (2) Then put the above mixture into the extruder, and slowly heat it, press the above mixture into tablets at a temperature of 100-155°C, and grind it into powder with a coarse powder machine after cooling:

[0039] (3) After that, use a fine powder machine to further pulverize the above-mentioned pulverized powder, and carry out classification, separation, and collection to obtain a primary product with a particle size of 5--12 μm:

[0040] (4) Add silicon dioxide, dimethyldichlorosilane and hexamethyldisilazane, and mix with a mixer to modify the surface so that the fluidity is greater than 20%.

[004...

example 3

[0044]

[0045] 10 kg of anti-counterfeiting ink is produced in each batch, and the proportion of the above formula components is controlled, and the production is made according to the following steps:

[0046] (1) Evenly mix polymer resin, polypropylene wax, black pigment, charge regulator and anti-counterfeiting material in a mixer to make a mixture;

[0047] (2) Then put the above mixture into the extruder, and slowly heat it, press the above mixture into tablets at a temperature of 100-155°C, and grind it into powder with a coarse powder machine after cooling:

[0048] (3) After that, use a fine powder machine to further pulverize the above-mentioned pulverized powder, and carry out classification, separation, and collection to obtain a primary product with a particle size of 5--12 μm:

[0049] (4) Add silicon dioxide, dimethyldichlorosilane and hexamethyldisilazane, and mix with a mixer to modify the surface so that the fluidity is greater than 20%.

[0050] (5) Scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com