A gas temperature control device

A technology for controlling device and gas temperature, which is applied in the field of lithography machines, and can solve problems such as inability to achieve high-precision temperature control and general temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

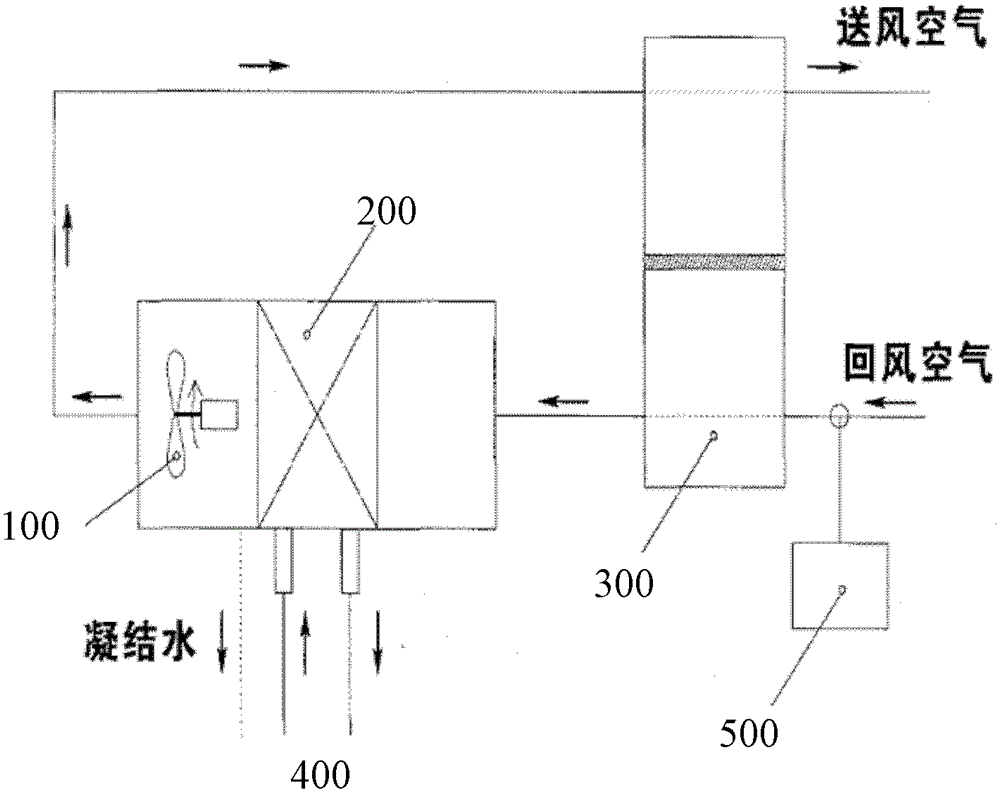

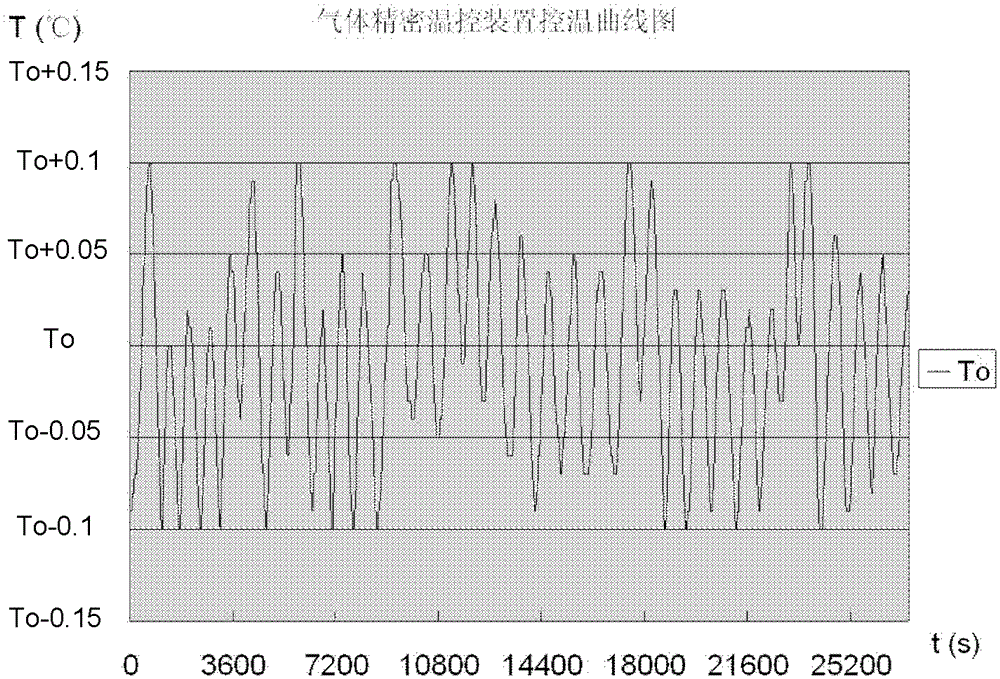

[0029] There are many heat sources inside the lithography machine, which affect the overall internal environment and have a great impact on its exposure performance. In order to ensure the temperature stability and uniformity of local key areas, a gas temperature control device for lithography machines is invented. Through this device, the temperature-controlled air is sent into the interior of the lithography machine, and a partial air bath is performed on the above-mentioned area, focusing on maintaining the environment of the key areas inside the machine and improving the exposure accuracy of the lithography machine.

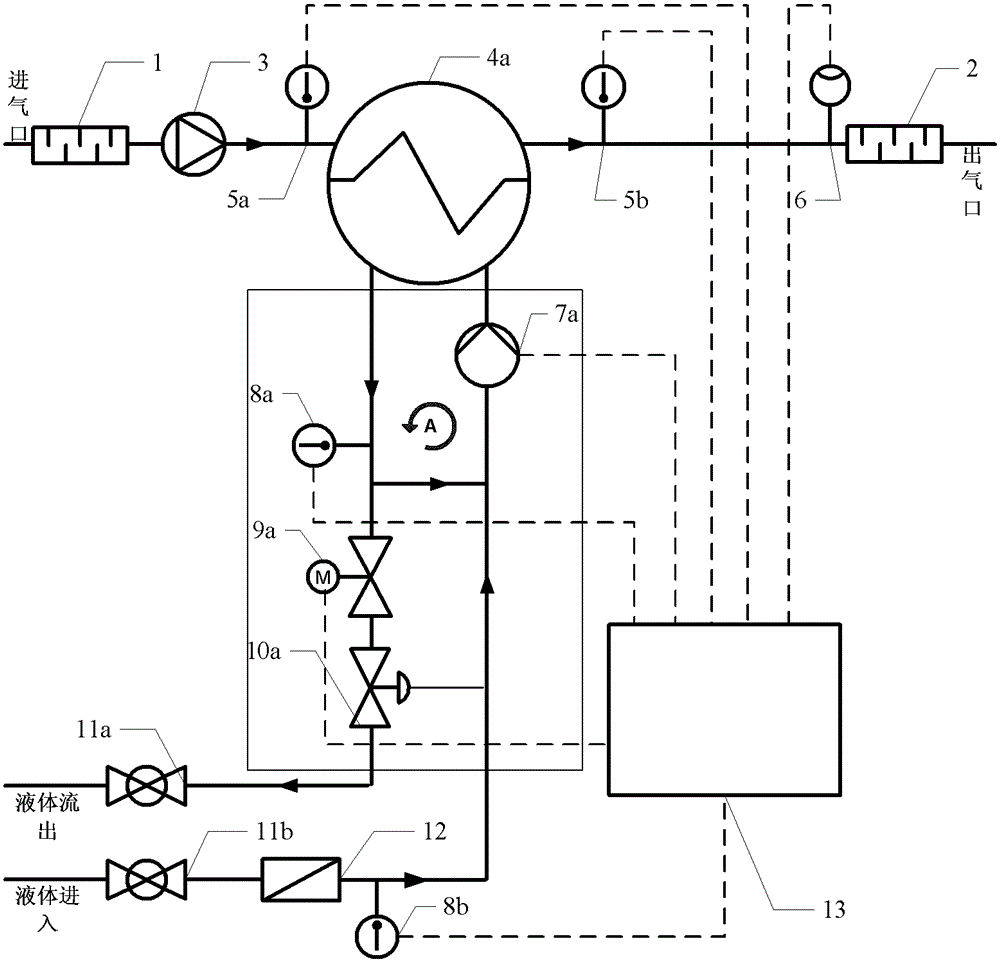

[0030] Please refer to figure 2 , figure 2 Shown is a schematic structural diagram of the gas temperature control device of the first preferred embodiment of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com