Tensile strength test clamp of automatic positioning screw

A tensile strength, automatic positioning technology, applied in the mechanical field, can solve the problems of high thread tripping risk, inconvenient use and operation, inaccurate test results, etc., and achieve the effect of shortening the test period, convenient use and operation, and high test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

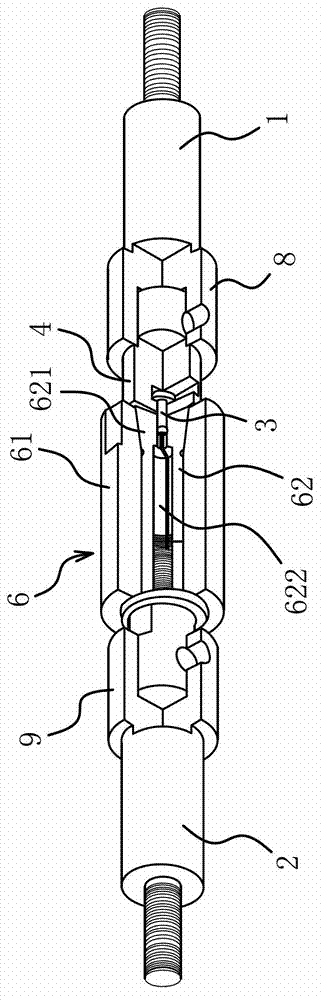

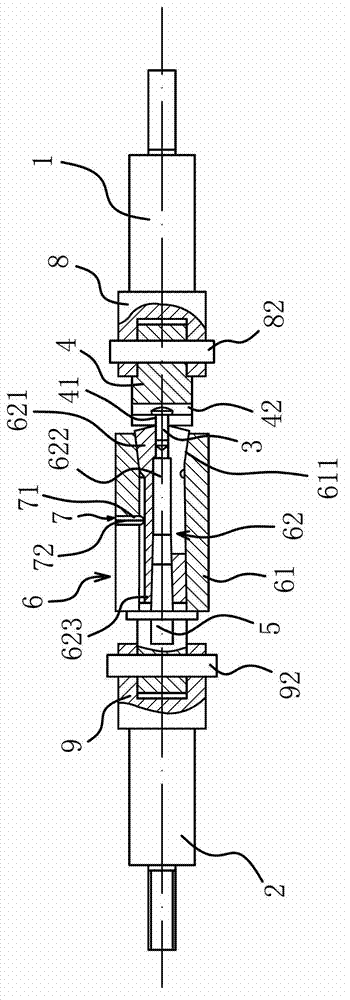

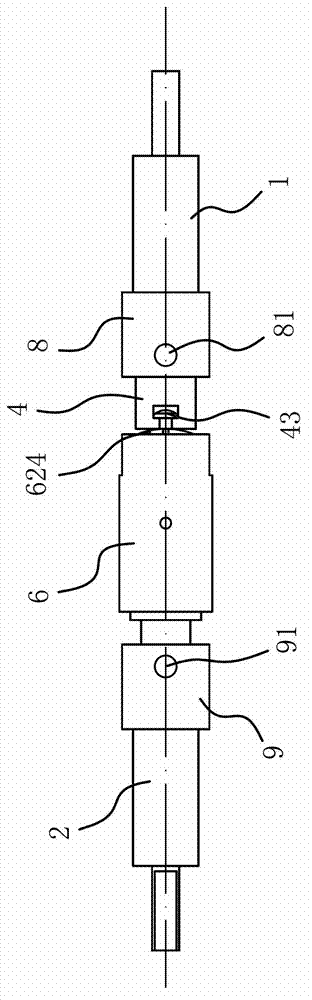

[0021] Such as Figure 1-3 As shown, the automatic positioning screw tensile strength test fixture includes a first connector 1 and a second connector 2, and the first connector 1 is provided with a mounting seat 4 for positioning the head of the screw 3 to be tested. Two connectors 2 are provided with a pull rod 5, and an adjustable clamping mechanism 6 for positioning the nail portion of the screw 3 to be tested is arranged between the mount 4 and the pull rod 5, and when the pull rod 5 moves axially away from the mount 4, the pull rod 5 can drive the adjustable clamping mechanism 6 to lock and position the nail portion of the screw 3 to be tested. The adjustable clamping mechanism 6 can be adjusted according to the size and specification of the screw 3 to be tested, and there is no need to replace the clamping mechanism, which shortens the test period and improves the test accuracy.

[0022] As a more optimized technical solution, in this embodiment, the adjustable clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com