Heating device used for through silicon via (TSV) fill copper residual stress measurement

A residual stress and heating device technology, applied in the direction of measuring devices, measuring force, instruments, etc., to prevent heat loss, reliable experimental results, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

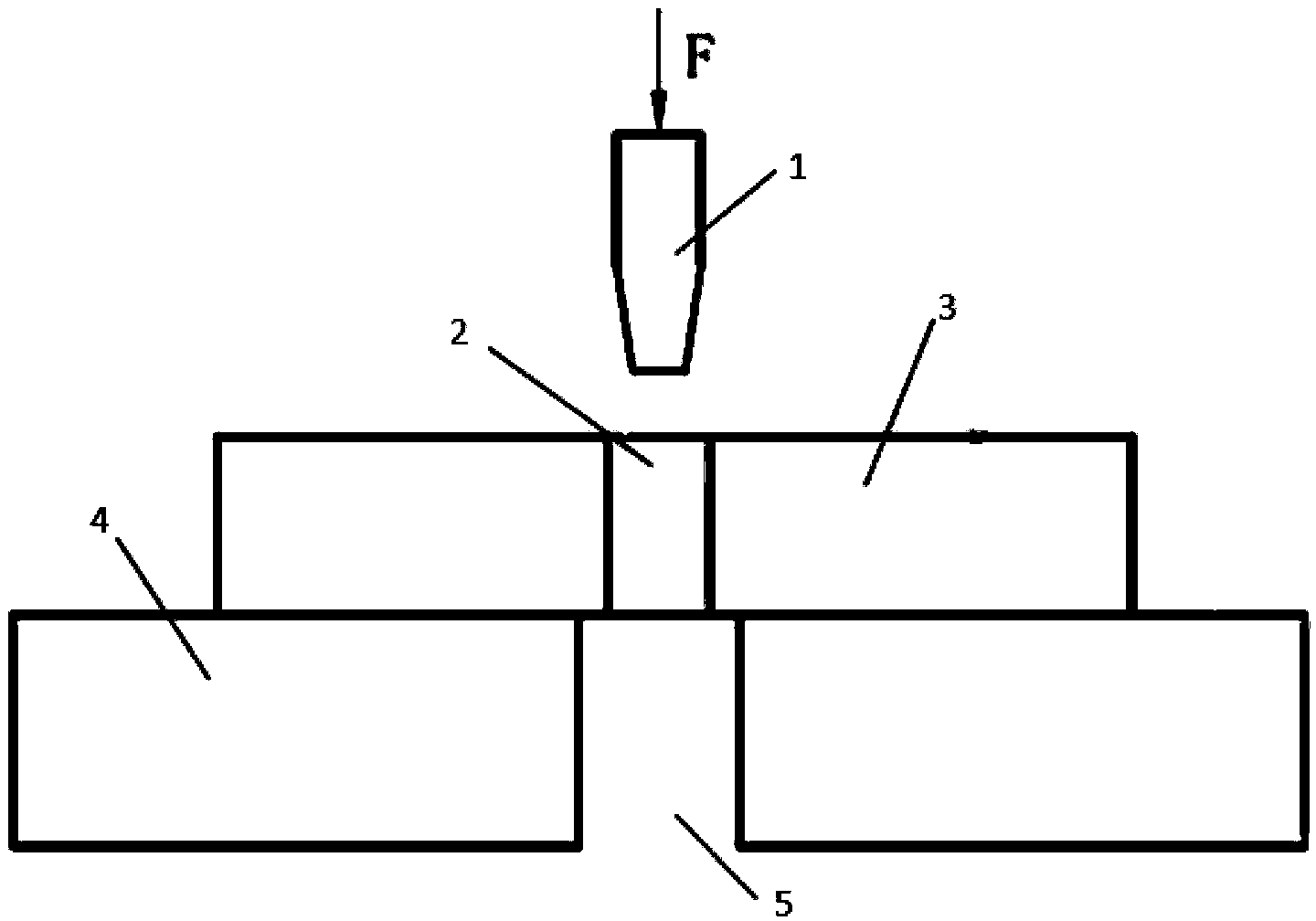

[0031] figure 1 It is a schematic diagram of the experimental principle. During the experiment, the sample carrier 4 is placed on the displacement stage of the nanoindenter, the copper column 2 is aligned with the indenter 1 of the nanoindenter, and the communication between the copper column 2 and the carrier is ensured. The hole 5 is centered, and the force in the direction shown in the figure is applied to press the copper column out of the TSV through hole, and the change of the load and displacement is recorded during the extrusion, and the load-displacement curve is obtained.

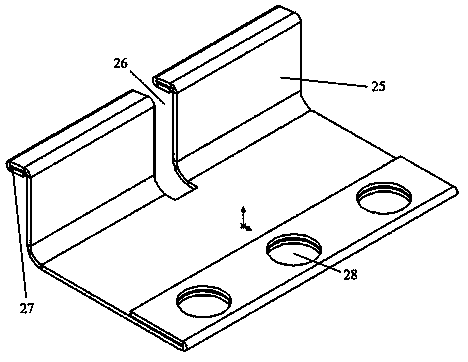

[0032] Figure 4 It is a schematic diagram of installing the TSV adapter plate 8 on the device according to the embodiment of the present invention. In the figure, the tightening spring piece 11 and the positioning spring piece 16 are fixed on the clamp seat 17 by the cross-recessed flat head scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com