Arc-shaped pipe based flow metering device and metering method for multiphase flow

A flow measurement and arc-shaped tube technology, which is applied in the measurement of flow/mass flow, measurement device, volume flow ratio measurement, etc., can solve problems such as unfavorable automation, many control links, and complicated separator maintenance and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

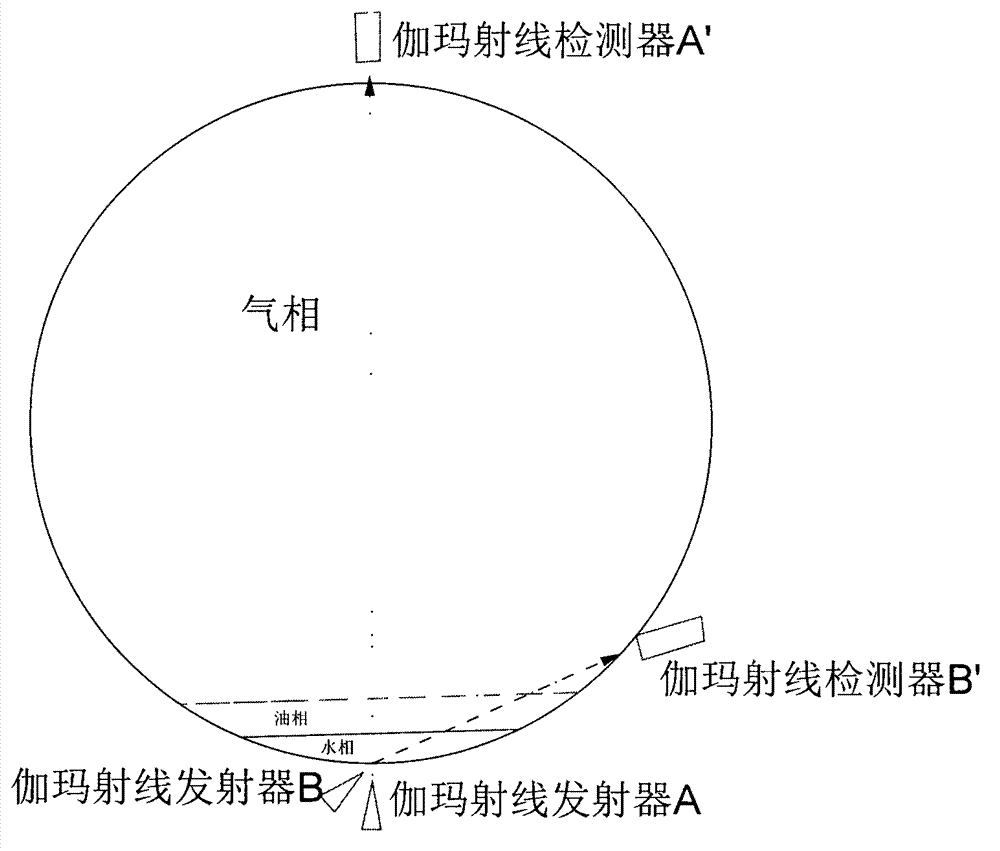

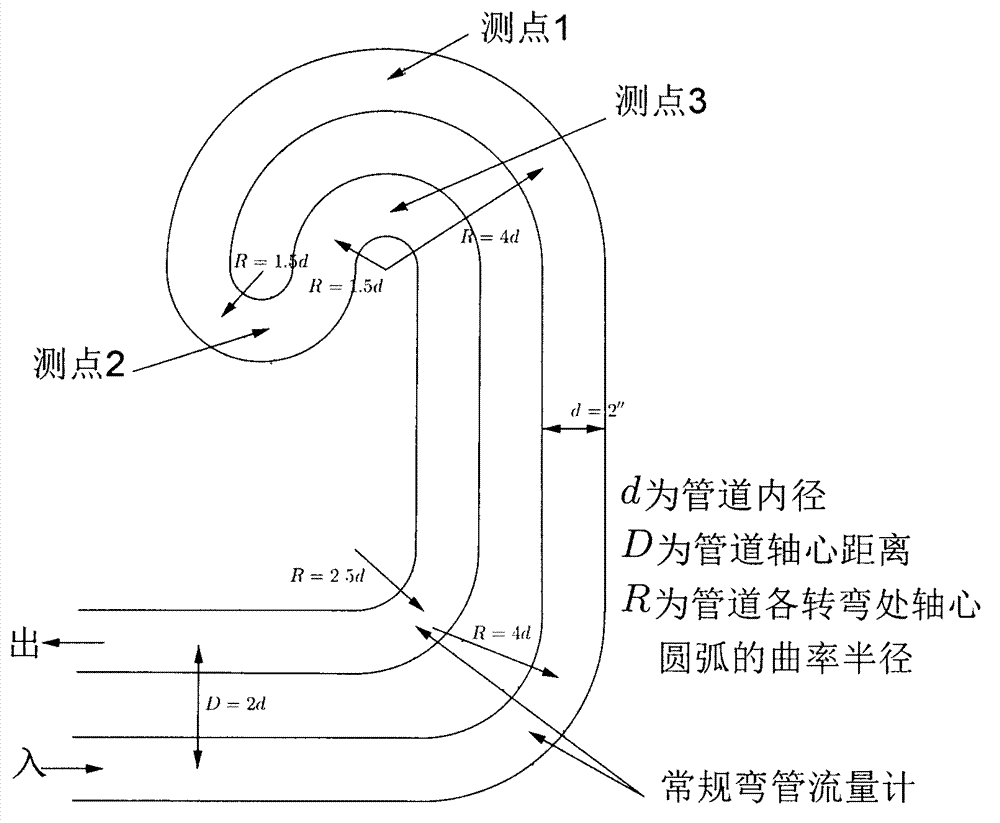

[0193] An exemplary preferred embodiment of the present invention is as image 3 As shown, the size relationship of each pipe is also plotted in the figure. where d is the inner diameter of the pipe. Wherein the pipeline may include multiple arc-shaped pipelines, and the curvature radius R of each arc-shaped pipeline is also plotted in the figure. Viewed along the direction of fluid flow, the first arc (R=4d) can be used as an upstream elbow flowmeter to measure total flow. It then optionally flows through a section of straight pipe, and then flows into a second curved pipe (R=4d), where the phase fraction measurement candidate 1 can be taken at the vertical section 1, where it can be measured in the vertical diameter direction or The gamma-ray detector is arranged in a non-radial direction, and the gamma-ray detector is a single-energy or dual-energy detector when gas-liquid two-phase measurement is performed; when gas, oil, and water three-phase measurement is performed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com