High-performance electric heating furnace oven

An electric heating furnace and high-efficiency technology, which can be used in household furnaces/stoves, electric heating fuels, and household heating, etc., can solve the problems of human injury, unsafe use, and low electric-heat conversion efficiency, and reduce radiation loss and electric conversion. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

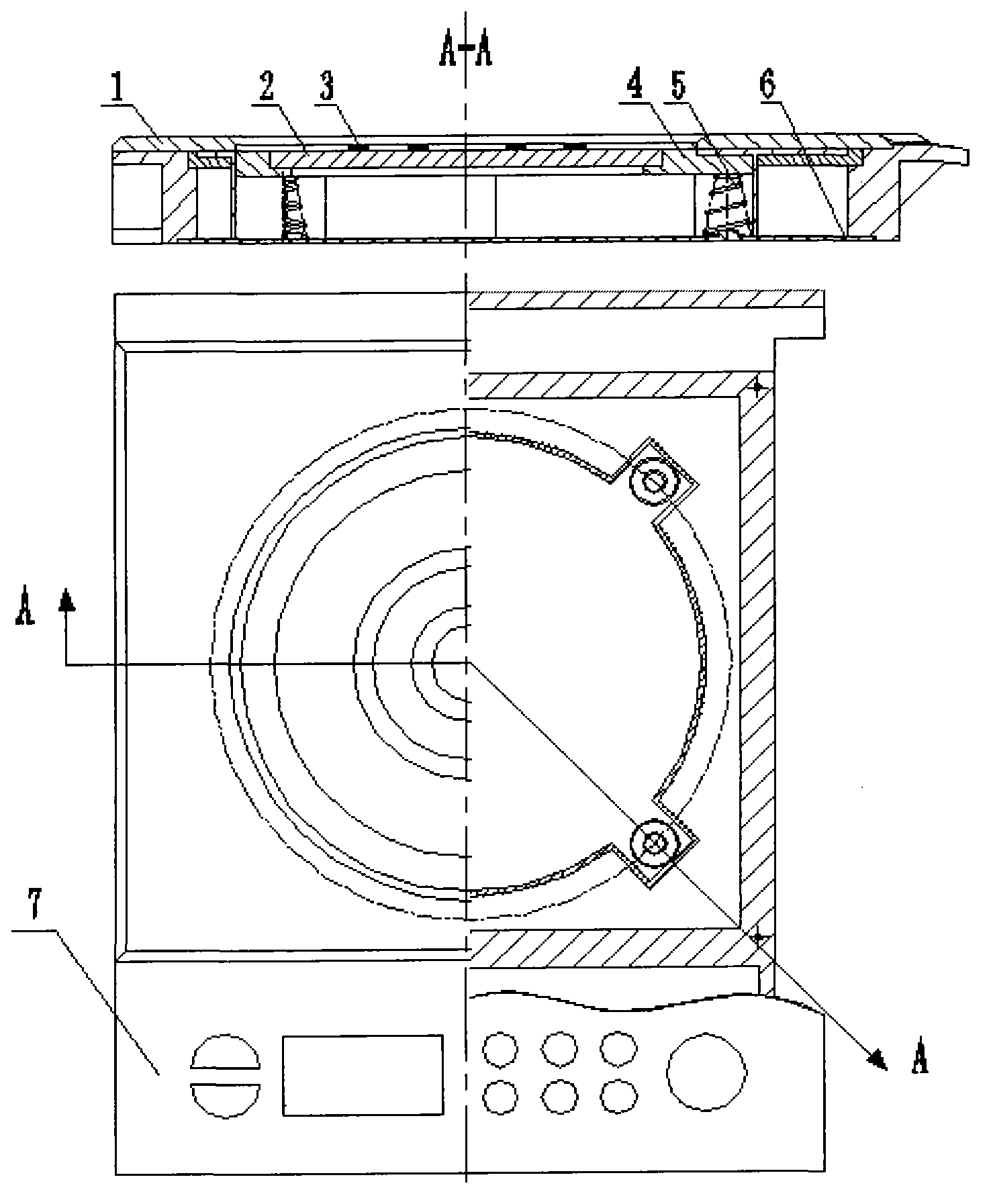

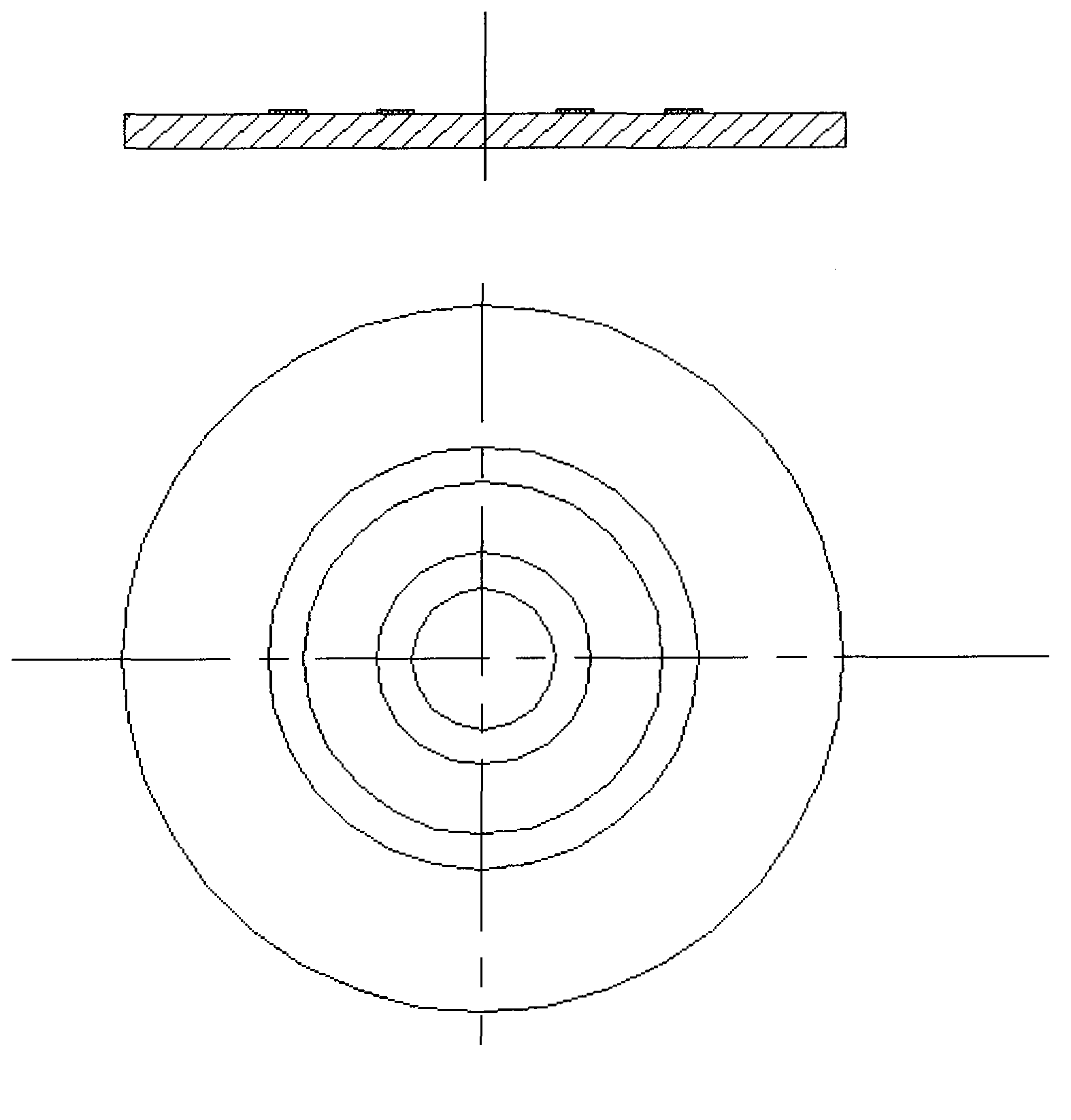

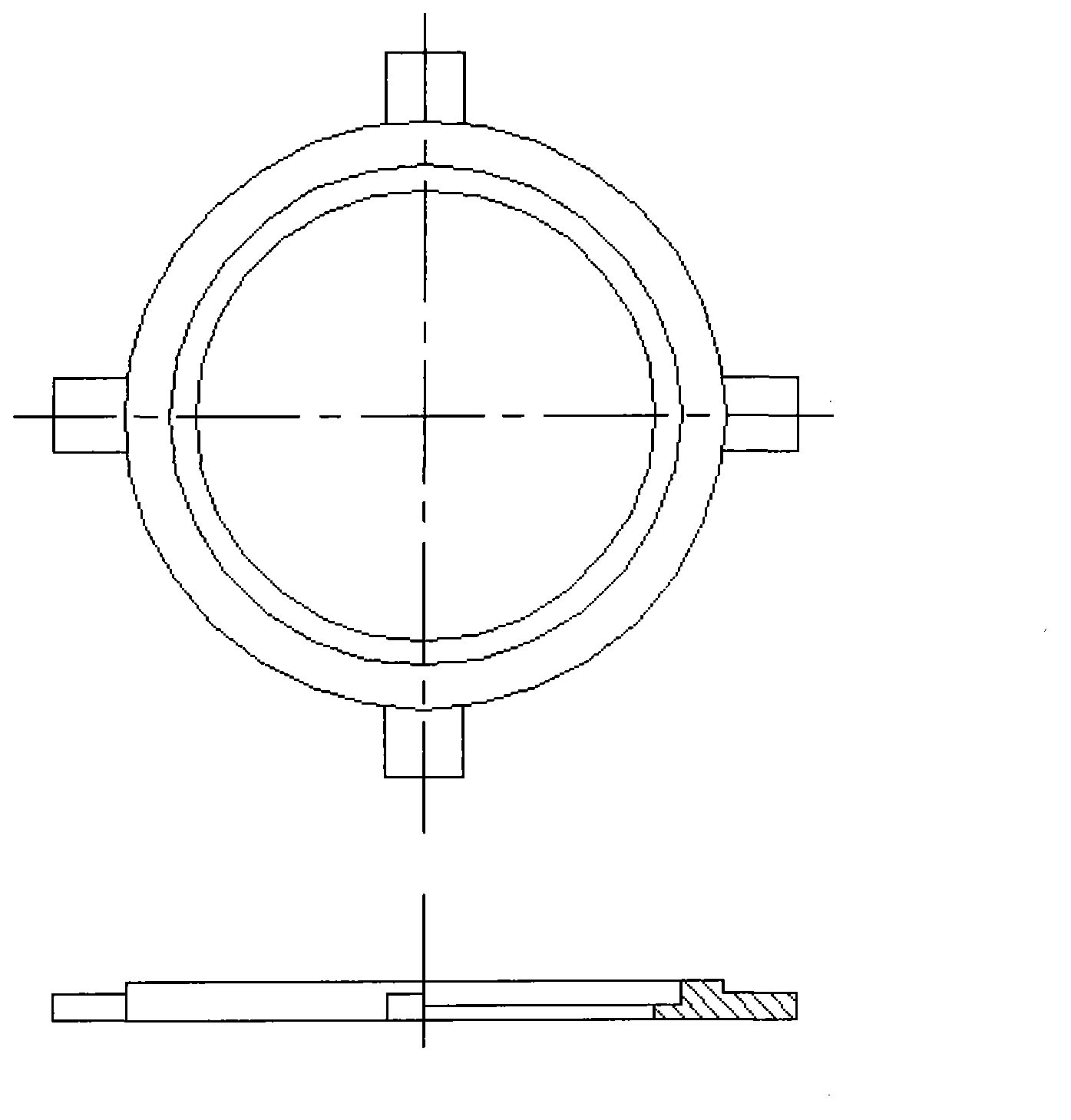

[0016] As shown in the figure, the upper surface of the heat insulation board 2 in the heating panel of the high-efficiency electric heating stove is sprayed with a thick electrothermal film. Various dielectric materials such as silicon, it can be seen that the heat shield 2 in the heating panel has a lot of room for selection, and the present invention preferably chooses glass-ceramics. The heat insulation board 2 in the heating panel is made into a disc shape, and the electric heating film heating ring 3 sprayed on the middle part of the heat insulation board 2 is connected to the electric electrode, and can be connected to an AC and DC power supply, and the voltage can be 5-400V Between, this just makes the scope of application of this electric stove wider. The lower end surface of the heating panel is provided with a lifting device, and the lifting device includes: a sliding plate 4 and a scroll spring 5 . The sliding plate 4 is fixedly connected with the scroll spring 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com