Novel aluminum alloy round pipe

A technology of aluminum alloy and round tube, applied in the direction of slender components, building components, etc., can solve the problems of aluminum alloy round tube application limitations, round tube depression or bending deformation, no reinforcement mechanism, etc., and achieve long service life , not easy to sag or bend and deform, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

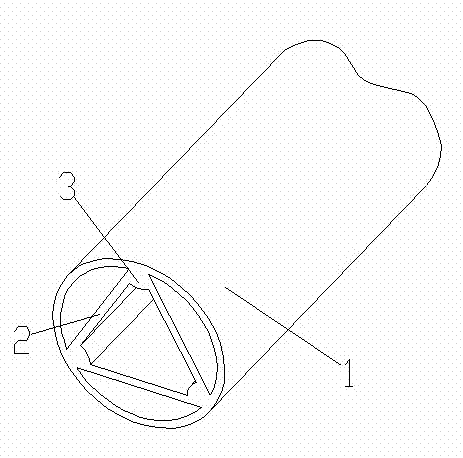

[0013] attached figure 1 It is a new type of aluminum alloy round tube according to the present invention, which includes an aluminum alloy round tube body 1, and a reinforcing rib 2 is provided on the inner wall of the aluminum alloy round tube body 1; there are three reinforcing ribs 2, which are first connected to each other On the inner wall of the aluminum alloy round tube body 1 . A fastening flange 3 is provided at the connection between the reinforcing ribs 2, which enhances the bending resistance structural strength of the aluminum alloy round tube body 1 and has good practical effect.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0015] A new type of aluminum alloy round tube of the present invention is provided with triangular reinforcing ribs inside the hollow rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com