Straight-flow shut-off valve sealed with elastic valve seat under fluid pressure

A technology of elastic valve seat and fluid pressure, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of space, position, location, etc., the operation is not very convenient, and can not be implemented, etc. , The effect of small operation force and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

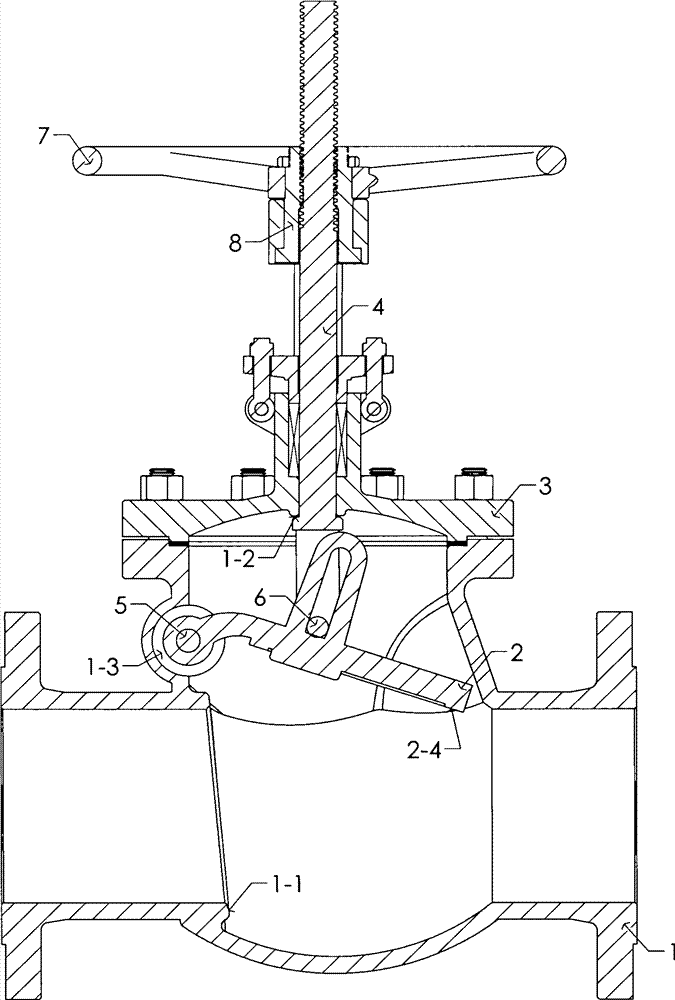

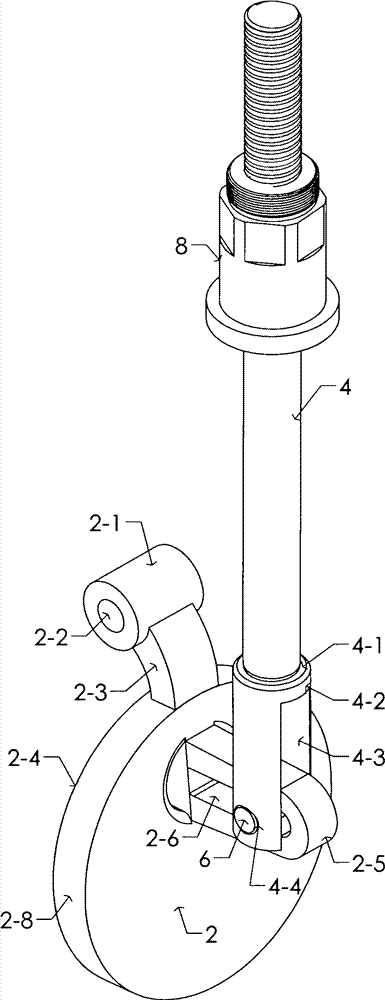

[0025] Example 1 as figure 1 and figure 2 As shown, the sealing body of the valve flap (2) is a circular platform (2-8), and the upper end of the peripheral surface has an additional cylindrical support body (2-1) formed along the center to both sides, and the support body (2-1) 1) The rib plate (2-3) and the two are connected, and one end is movably supported in the semicircular annular groove (1-3) protruding outward from the upper part of the valve body (1), and the pin shaft (5) passes through the valve The shaft hole on the body and the hole (2-2) on the support body (2-1) are connected to each other.

[0026] One side of the round table (2-8) on the valve disc (2) is provided with a connecting body (2-5) protruding to one side at the upper part of the center circle, and the groove in the valve stem (4) big head (4-2) The port (4-3) cooperates with the two planes of the connecting body (2-5), wherein the chute (2-6) and the pin hole (4-4) placed at the end of the valv...

Embodiment 2

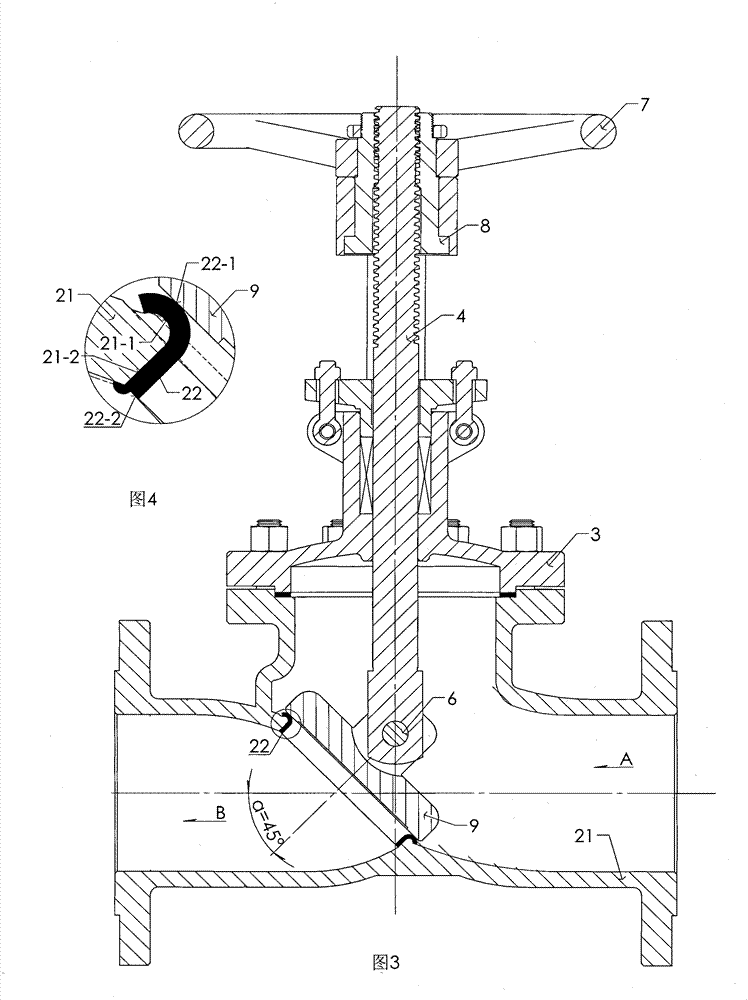

[0029] Example 2 as image 3 and Figure 4 Shown, the angle a=45 ° of valve body (21) inlet runner (A) and outlet runner (B).

[0030] The circular arc of the sealing end (22-1) of the elastic valve seat (22) is consistent with the circular arc (21-1) of the valve body (21), and the outer circle is consistent with the flow channel hole (21) in the valve body (21). -2) Cooperate.

[0031] The circular arc of the sealing end (22-1) of the elastic valve seat (22) is consistent with the circular arc (21-1) in the valve body (21), and the outer circle is consistent with the flow channel hole (21) in the valve body (21). -2) Cooperate, the end face (22-2) of the elastic valve seat (22) is integrated with the joint of the valve body (21-3) by welding.

Embodiment 3

[0032] Example 3 as Figure 5 and Figure 6 Shown, the angle a=45 ° of the flange (31-3) of valve body (31) outlet channel (B) and the flange (32-3) of bonnet (32) inlet channel (A).

[0033] The arc of the sealing end (35-1) of the elastic valve seat (35) is consistent with the arc (31-1) of the valve body (31), and the lower gasket (34) is placed in the groove of the valve body (31) In (31-2), the lower surface of the outer circle of the lower gasket (34) is in contact with and sealed with the lower plane of the outer circle of the elastic valve seat (35), and one side of the upper gasket (33) is in contact with the center of the valve cover (32). The flat surface (32-1) of the boss is in contact with and sealed, and the other side is in contact with and sealed with the upper plane of the outer circle of the elastic valve seat (35).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com