Internal gear pump

一种齿轮式、齿顶的技术,应用在旋转活塞式泵、泵、旋转活塞式机械等方向,能够解决无法提高容积效率、无法减小运送侧顶端间隙等问题,达到静音性良好、抑制泄露、提高泵效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

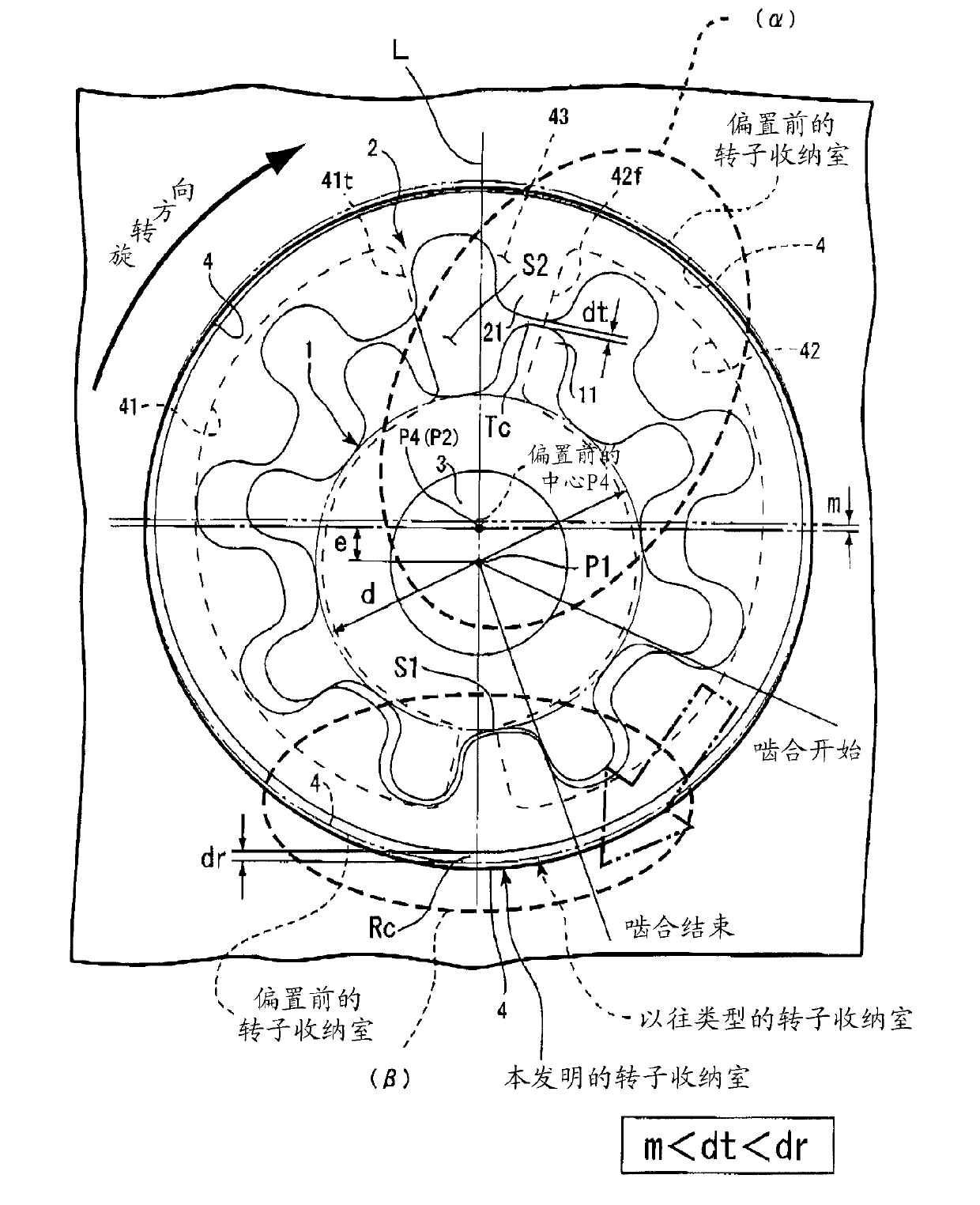

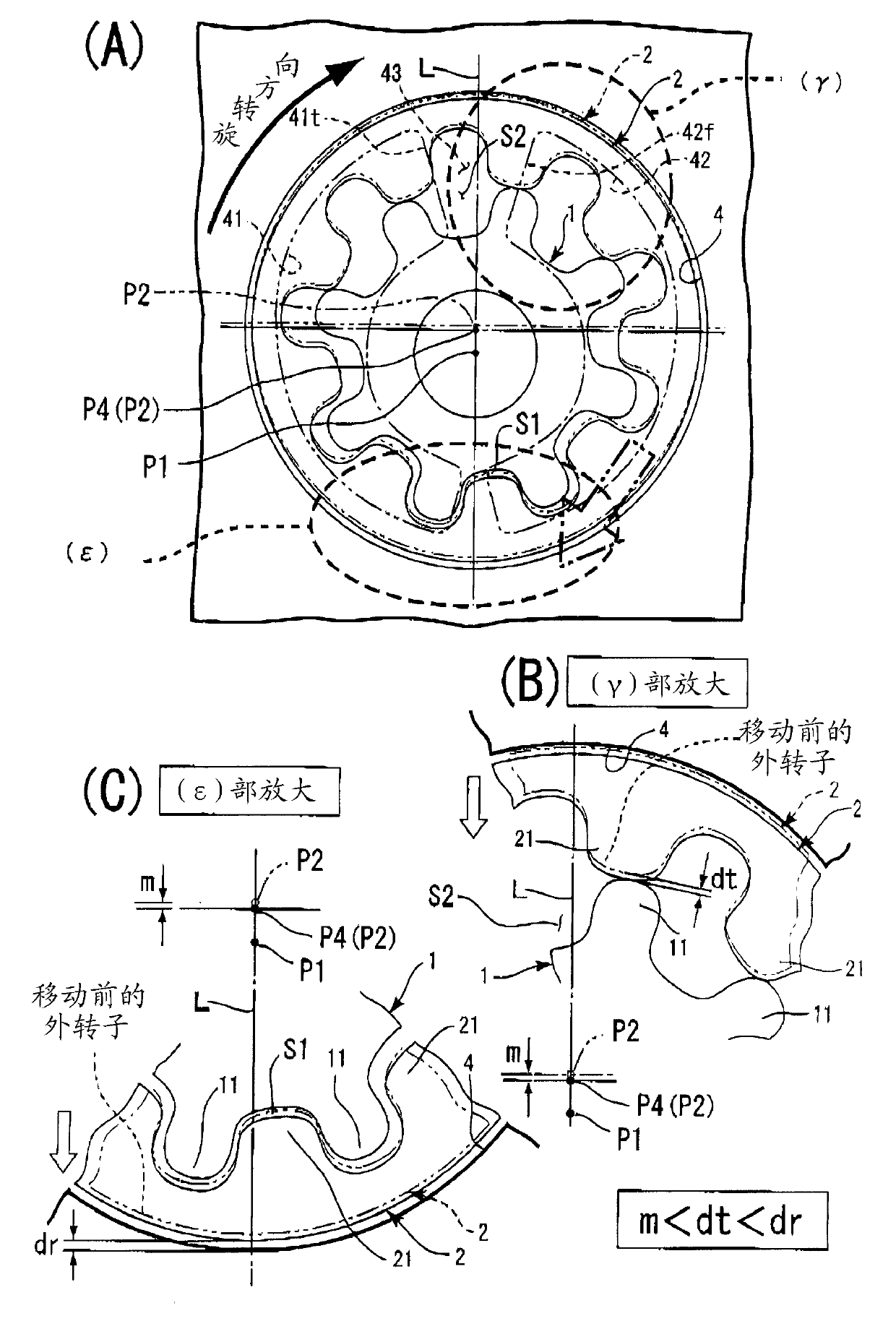

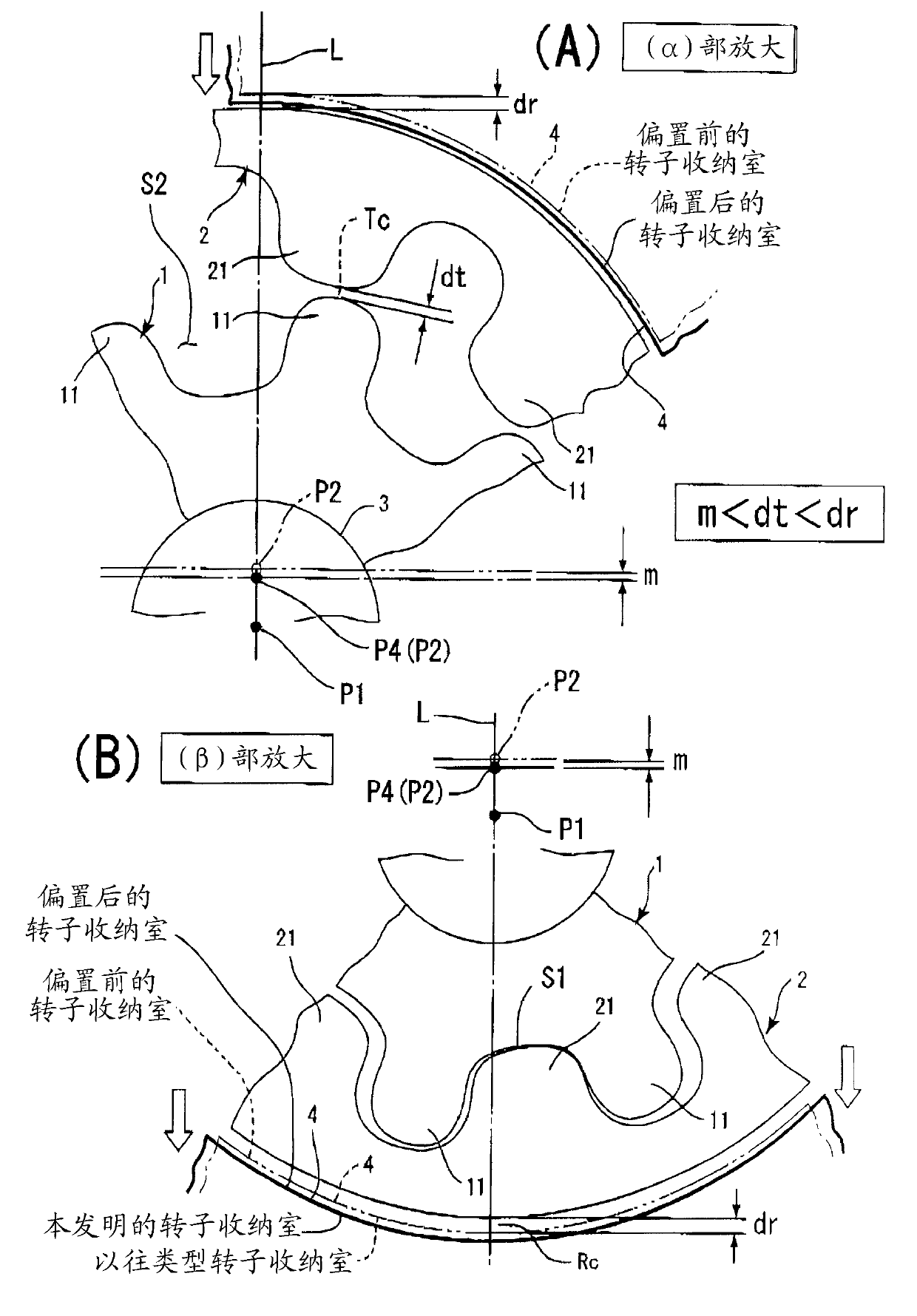

[0028] Hereinafter, embodiments of the present invention will be described based on the drawings. In the present invention, the pump rotor constitutes the rotor of the internally connected gear pump, specifically, the inner rotor 1 and the outer rotor 2 (refer to figure 1 ). The inner rotor 1 is a gear with external teeth, and the outer rotor 2 is a gear with internal teeth. exist figure 1 In , the arrows of the two-dot chain line described in the range from the meshing start to the meshing end indicate the force applied from the inner rotor 1 to the outer rotor 2 .

[0029] Furthermore, the pump rotor is not a trochoidal tooth shape, but a so-called high-volume tooth shape that realizes an increase in the theoretical discharge amount. The high-volume tooth profile, for example, the tooth profile 11 of the inner rotor 1 is formed by combining a plurality of ellipses and circles, or curves of higher order.

[0030] In the present invention, in the pump rotor, let the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com