Construction method of longitudinal opening long-span large-volume concrete tunnel lining structure

A mass concrete and construction method technology, applied in tunnel lining, tunnel, shaft lining, etc., can solve problems affecting structural safety, difficulty in ensuring structural safety and reliability, and reduced section rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

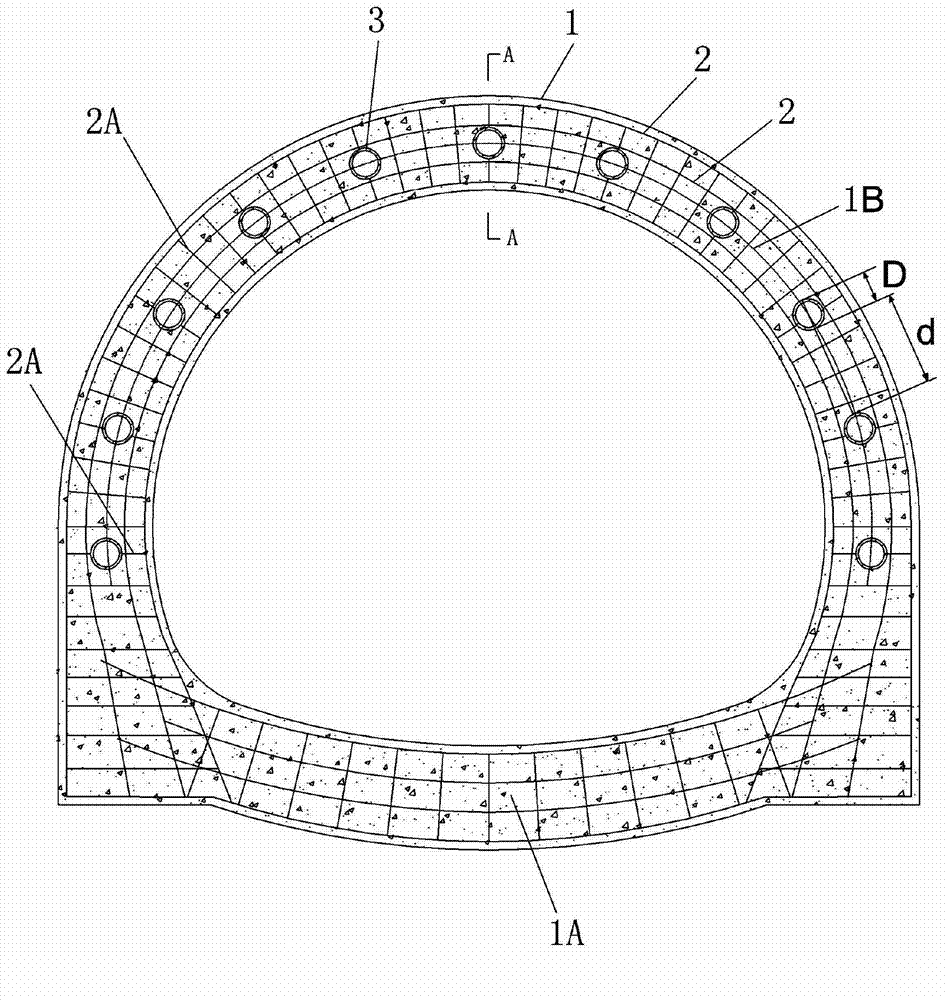

[0022] figure 1 , figure 2 Shown, a kind of specific embodiment of the present invention is: a kind of construction method of long-span mass concrete tunnel lining structure with longitudinal opening, and its method is:

[0023] a. Set up the formwork at the construction site of the lining 1 and bind the lining reinforcement 2;

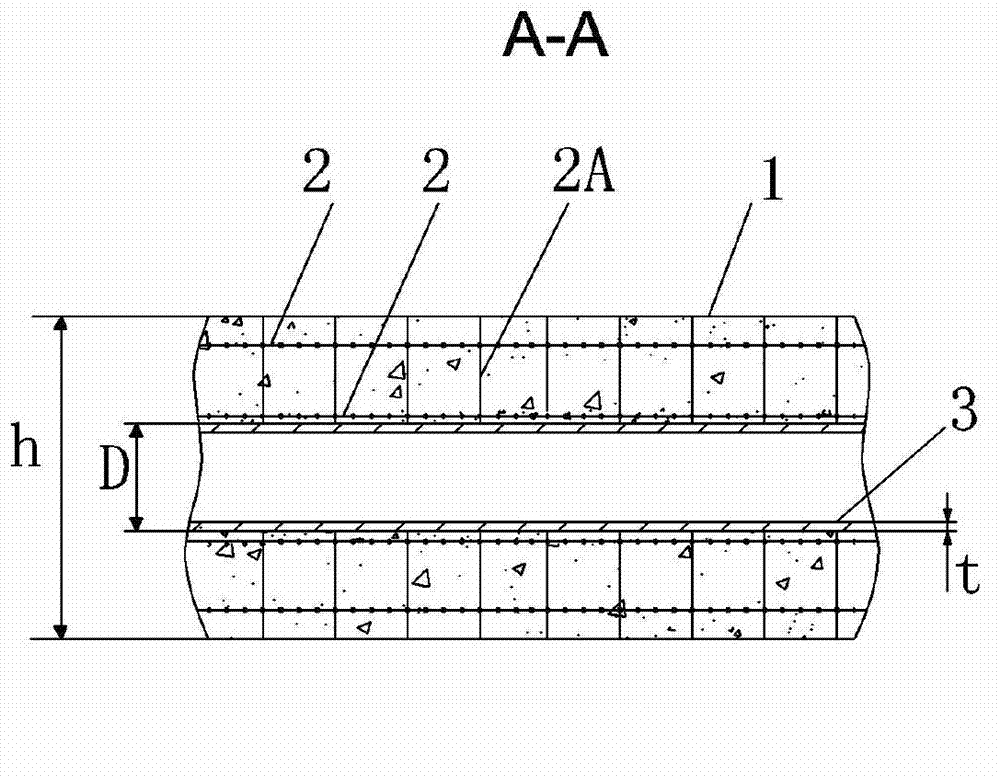

[0024] b. Place the steel pipes 3 longitudinally on the circumferential axis 1B of the lining 1 above the inverted arch 1A, and distribute them at equal intervals along the circumferential axis 1B, and weld the steel pipes 3 to the erecting bars 2A of the lining steel bars 2;

[0025] c. Pouring concrete.

[0026] The diameter D of the steel pipe 3 used in this example is 1 / 10 to 1 / 2 of the lining thickness h, the wall thickness t of the steel pipe 3 is 10 to 30 mm, and the circumferential distance d between adjacent steel pipes 3 is 2 to 1 / 2 of the diameter D of the steel pipe 3. 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com