OAC (Optimum Asphalt Content) design method of modified asphalt concrete mixture in target mix proportion stage

A technology of modified asphalt and design method, which is applied in the field of asphalt concrete, can solve problems such as complex engineering, achieve the effects of simple steps, objective results, and reduced design time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

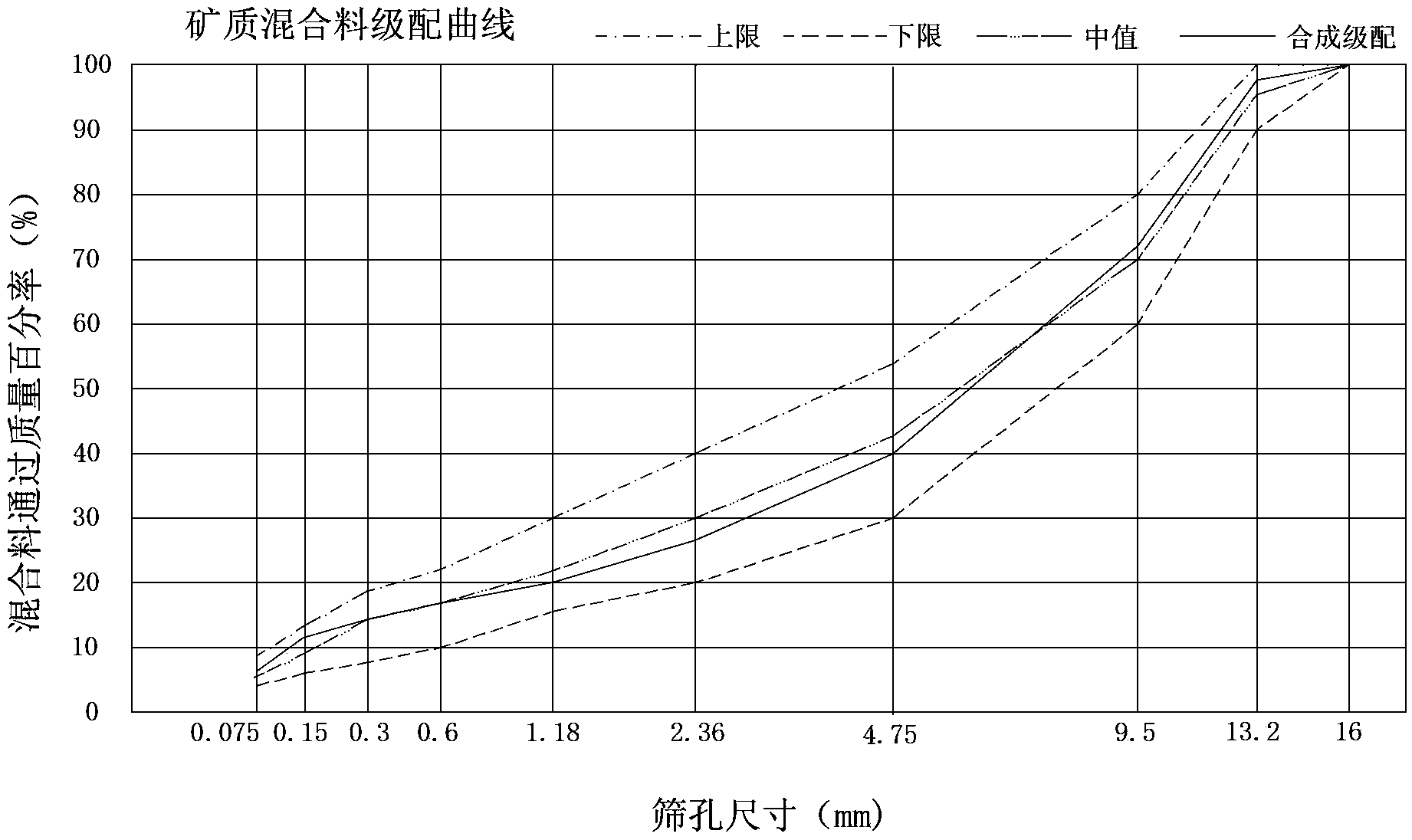

[0029] Example 1 This example is an example of laying AC-13 Qingchuanyan asphalt modified asphalt surface on a certain level of highway section in Chengdu, Sichuan.

[0030] 1. Required equipment, see Table 1

[0031] Table 1. Required equipment

[0032] Serial number

Name

Unit

Quantity

Remarks

1

Taiwan

1

2

Level

Taiwan

2

DZS3-1 type

3

Taiwan

1

4

Electronic scale

Taiwan

1

46kg range, 0.1g sense

5

Electronic scale

Taiwan

1

The range is 300~500g, the sensitivity is 0.001g

6

Marshall Stability Tester

Taiwan

1

LD190-II

7

Rutting test forming machine

Taiwan

2

8

Stone standard sieve

set

1

2.5~100mm

9

Sand standard sieve

set

1

0.16~5mm

10

Asphalt Penetration Tester

Taiwan

1

Measure the penetration value and calculate the PI

11

Marshall Tester

Taiwan

1

12

Asphalt Extractor

Taiwan

1

13

Marshall Stripper

Taiwan

1

14

Temperature control asphalt mixing machine

Taiwan

1

15

Constant tempe...

Embodiment 2

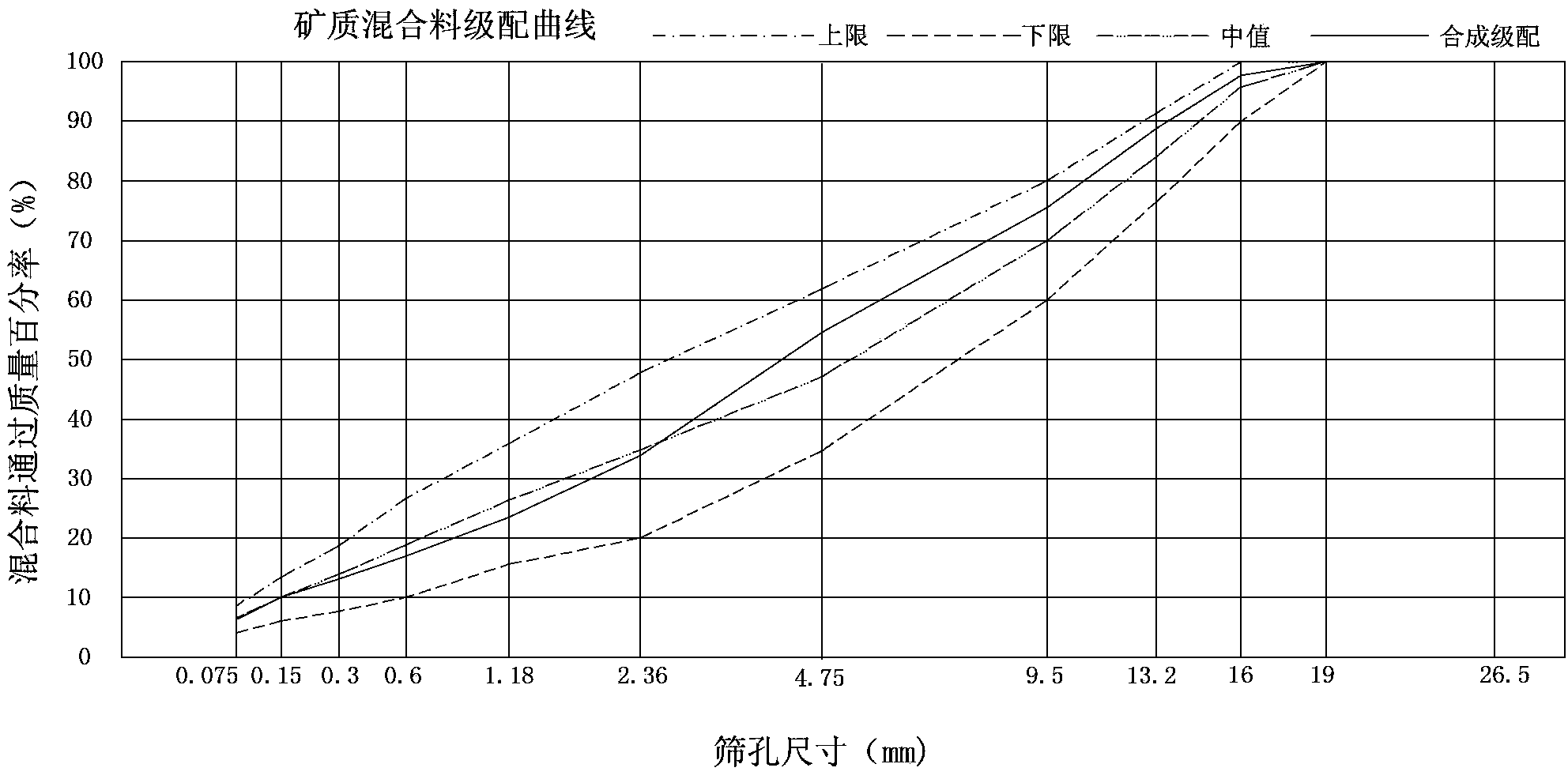

[0071] Example 2 This example is an example of laying AC-16 modified asphalt surface layer in a road reconstruction project in Chengdu Hi-tech Park.

[0072] 1. The equipment required is the same as Table 1 in Example 1.

[0073] 2. Material

[0074] (1) Modified asphalt: SBS modified asphalt, accounting for 4% by weight.

[0075] (2) Matrix asphalt: AH-70, accounting for 96% by weight.

[0076] (3) Aggregate and filler

[0077] ①Coarse aggregate: 1# crushed stone (13.2mm-16mm), 2# crushed stone (9.5mm-13.2mm), 3# crushed stone (4.75mm-9.5mm).

[0078] ②Fine aggregate: stone chips (0mm-4.75mm).

[0079] ③ Filler: mineral powder.

[0080] 3. Mineral material grading

[0081] Mineral material grading is carried out in accordance with "Technical Specification for Highway Asphalt Pavement Construction" JTG_F40-2004, see Table 5. AC-16 mineral material screening and composite grading curve diagram figure 2 .

[0082] 5. AC-16 mineral material screening and synthesis grading table

[0083]

[0084]...

Embodiment 3

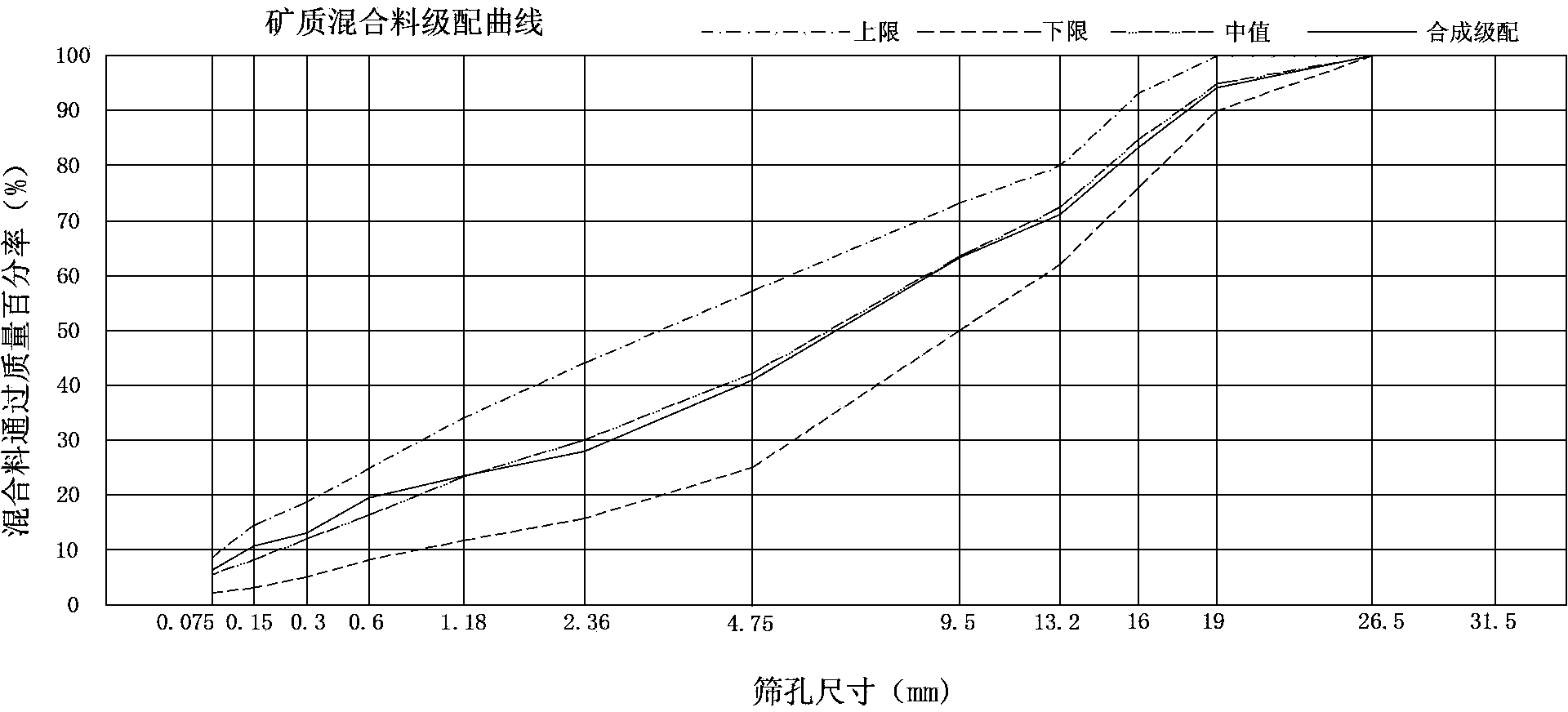

[0103] Example 3 This example is an example of the AC-20 modified asphalt surface layer of the Jiaotongda Road Reconstruction Project in Chengdu, Sichuan Province.

[0104] 1. The equipment required is the same as Table 1 in Example 1.

[0105] 2. Material

[0106] (1) Modified bitumen bitumen: BRA modified bitumen, accounting for 35% by weight.

[0107] (2) Base asphalt: No. 70 A grade road petroleum asphalt, accounting for 65% by weight.

[0108] (3) Aggregate and mineral powder

[0109] ①Coarse aggregate: 1# crushed stone (10mm-20mm), 2# crushed stone (5mm-15mm), 3# crushed stone (5mm-10mm).

[0110] ②Fine aggregate: stone chips (0mm-5mm).

[0111] ③ Filler: mineral powder.

[0112] 3. Mineral material grading

[0113] Mineral material grading is carried out in accordance with "Technical Specification for Highway Asphalt Pavement Construction" JTG_F40-2004, see Table 8 for details: AC-20 mineral material screening and composite grading curve diagram image 3 .

[0114] Table 8. AC-20 Miner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com